Cutting improver and preparation method thereof

A technology of improving agents and raw materials, applied in the field of powder metallurgy, can solve the problems of reducing the strength and toughness of materials, and achieve the effects of improving cutting performance, conducive to stress concentration, and reducing intermittent impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

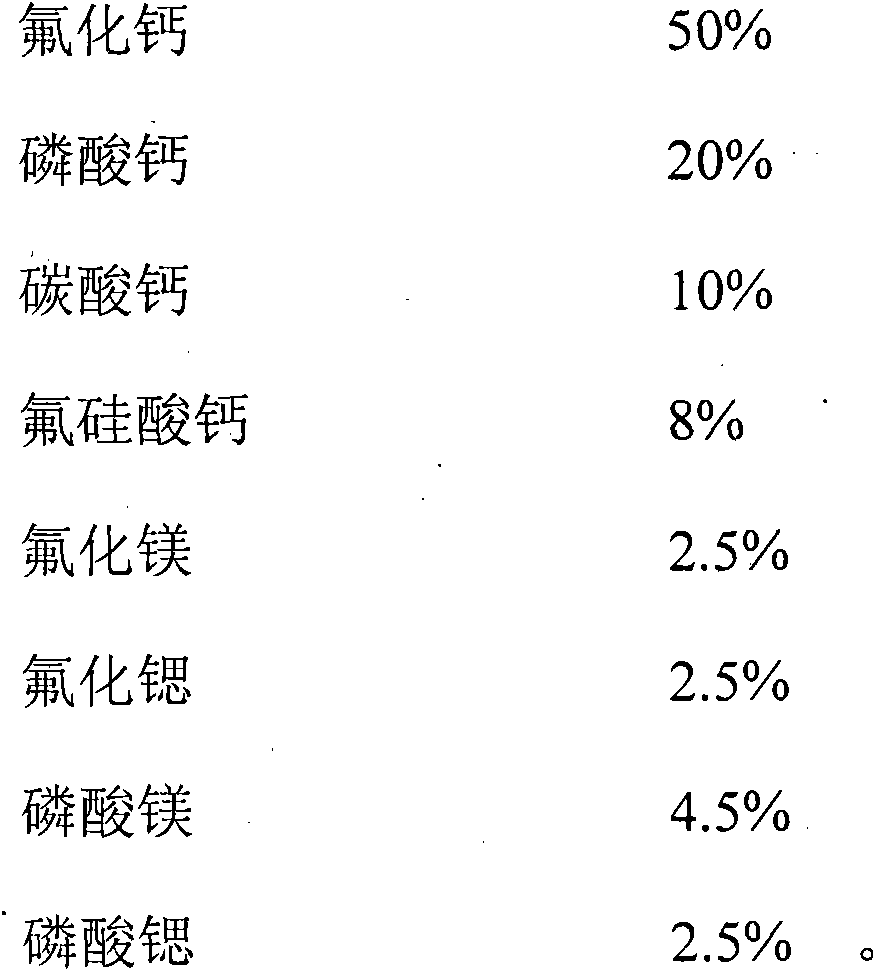

[0024] A cutting improving agent is characterized in that it is made of the following raw materials in weight percentage: 50% of calcium fluoride, 20% of calcium phosphate, 10% of calcium carbonate, 8% of calcium fluorosilicate, 2.5% of magnesium fluoride, fluoride Strontium 2.5%, magnesium phosphate 4.5%, strontium phosphate 2.5%.

[0025] The preparation method of above-mentioned cutting improving agent, comprises the following steps:

[0026] ① Weigh raw materials according to the above weight percentage;

[0027] ②Mix the raw materials weighed in step ① by a dry powder mixer for 10 minutes;

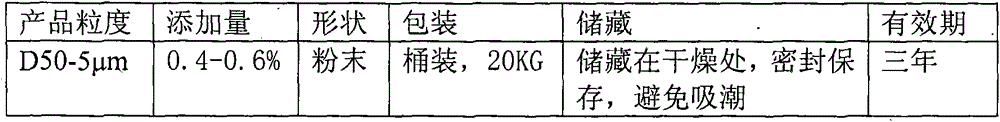

[0028] ③ The raw material treated in step ② is crushed by air flow until the D50 is less than 5 μm to obtain the finished product.

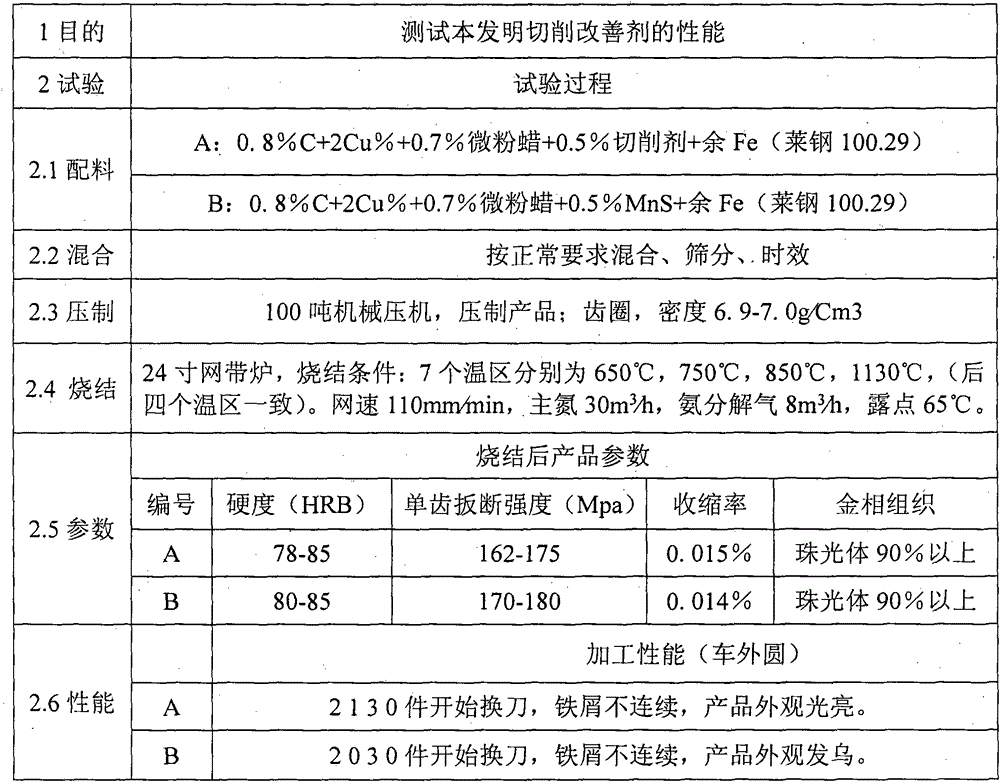

[0029] The performance data of the above-mentioned cutting improver are shown in Table 1 below:

[0030]

[0031] The cutting improving agent of the present invention is used in powder metallurgy products, compared with the commonly used manganese ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com