Method for preparing strontium fluoride or rare-earth doped strontium fluoride film by adopting electrolytic deposition

A rare earth doping, strontium fluoride technology, applied in chemical instruments and methods, electrolytic inorganic material coating, single crystal growth and other directions, can solve problems such as hindering universal application, complex equipment experimental procedures, etc., to achieve simple equipment and fast deposition rate. , the effect of good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Clean the ITO conductive glass twice with acetone, then clean the ITO conductive glass in an ultrasonic cleaner with deionized water for 10 minutes, then place the ITO conductive glass in a 10% nitric acid solution to activate it for 10 seconds, and finally use Deionized water cleaning, stand-by;

[0020] 2) In the 0.01 mol / liter disodium edetate and strontium ion complex solution, add 0.02 mol / liter sodium ascorbate, then add 0.04 mol / liter ammonium fluoride solution, adjust the pH value of the solution to 6, Obtain electrolyte, stand-by;

[0021] 3) Use ITO conductive glass as the working electrode, the platinum electrode as the counter electrode, and the calomel electrode as the reference electrode to form a three-electrode system, place it in the electrolyte for electrodeposition, and the anode deposition potential relative to the calomel electrode is 0.8V, The deposition temperature is 25° C. to obtain a strontium fluoride thin film.

Embodiment 2

[0023] 1) Clean the ITO conductive glass with acetone for 3 times, then clean the ITO conductive glass in an ultrasonic cleaner with deionized water for 30 minutes, then put the ITO conductive glass in 10% nitric acid solution to activate for 30 seconds, and finally use Deionized water cleaning, stand-by;

[0024] 2) In the 0.5 mol / liter disodium edetate and strontium ion complex solution, add 1 mol / liter sodium ascorbate, then add 2 mol / liter ammonium fluoride solution, adjust the pH value of the solution to 9, Obtain electrolyte, stand-by;

[0025] 3) Use ITO conductive glass as the working electrode, the platinum electrode as the counter electrode, and the calomel electrode as the reference electrode to form a three-electrode system, which is placed in the electrolyte for electrodeposition. The anode deposition potential relative to the calomel electrode is 1.4V. The deposition temperature is 50° C. to obtain a strontium fluoride thin film.

Embodiment 3

[0027] 1) Clean the ITO conductive glass twice with acetone, then clean the ITO conductive glass in an ultrasonic cleaner with deionized water for 15 minutes, then place the ITO conductive glass in a 10% nitric acid solution to activate it for 15 seconds, and finally use Deionized water cleaning, stand-by;

[0028] 2) In the 0.02 mol / liter disodium edetate and strontium ion complex solution, add 0.04 mol / liter sodium ascorbate, then add 0.08 mol / liter ammonium fluoride solution, adjust the pH value of the solution to 7, Obtain electrolyte, stand-by;

[0029] 3) Use ITO conductive glass as the working electrode, the platinum electrode as the counter electrode, and the calomel electrode as the reference electrode to form a three-electrode system, which is placed in the electrolyte for electrodeposition. The anode deposition potential relative to the calomel electrode is 1.1V. The deposition temperature is 30° C. to obtain a strontium fluoride thin film.

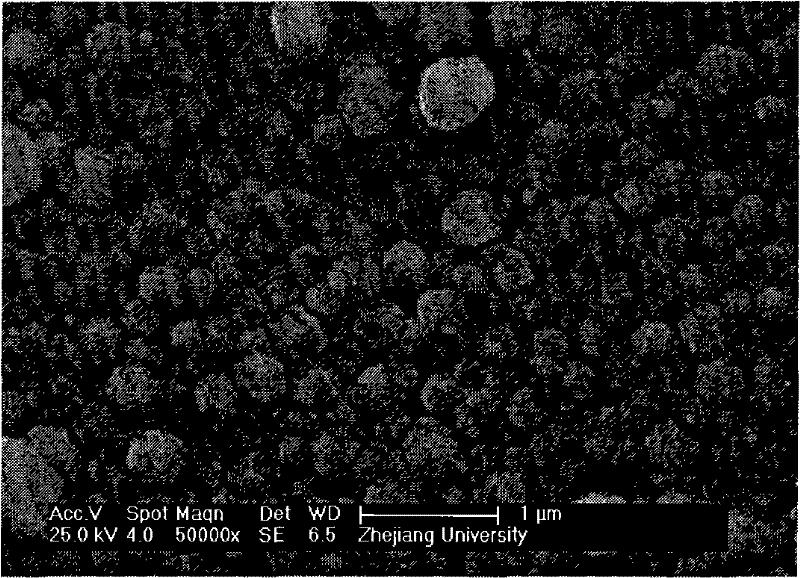

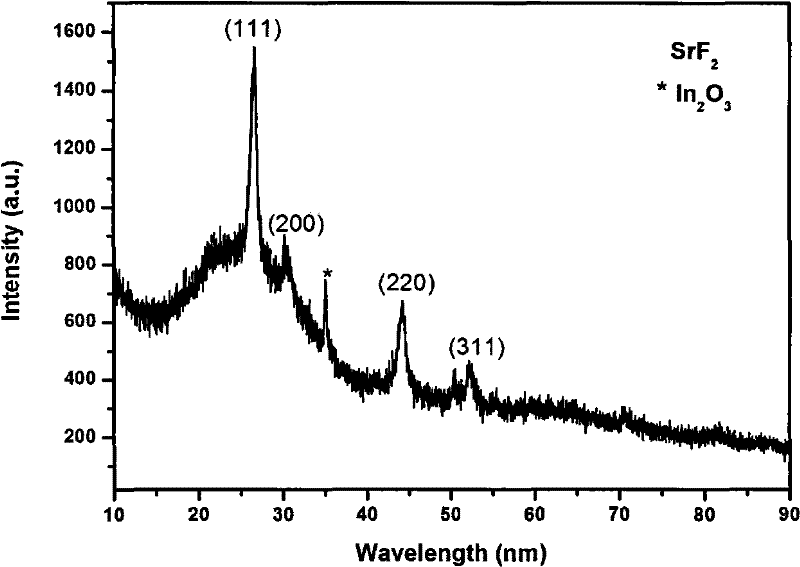

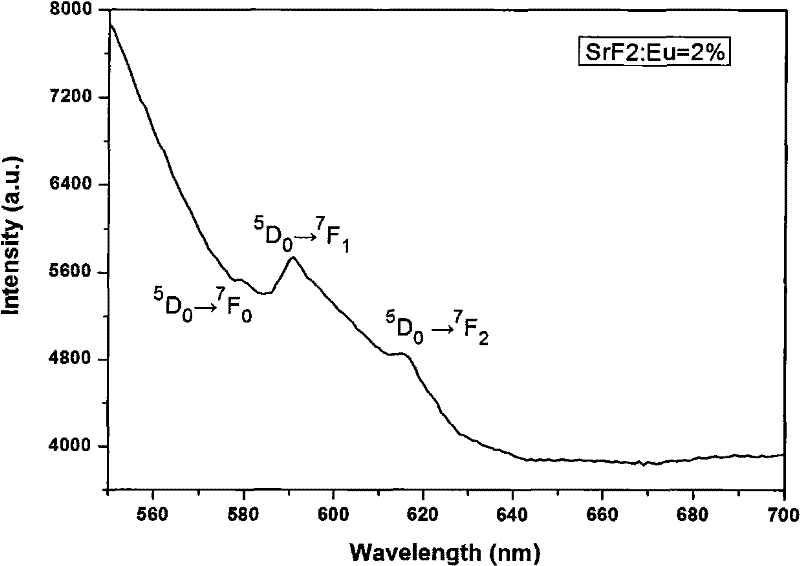

[0030] The structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com