A new approach to quantum tailoring to improve the efficiency of thin-film silicon solar cells

A solar cell and quantum tailoring technology, applied in the field of solar cells, can solve the problems of low-energy photon energy waste, high-energy photon energy loss, light energy loss, etc., so as to avoid the decline of conversion efficiency, avoid the decline of battery performance, and improve the conversion efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] In silicon thin film solar cells, due to the thin film thickness of silicon thin film, the absorption of incident visible light is very weak, which seriously limits the photoelectric conversion efficiency of the cell. It is a very attractive and effective way to increase the effective absorption of incident light in the 400-760nm band by increasing the silicon thin film.

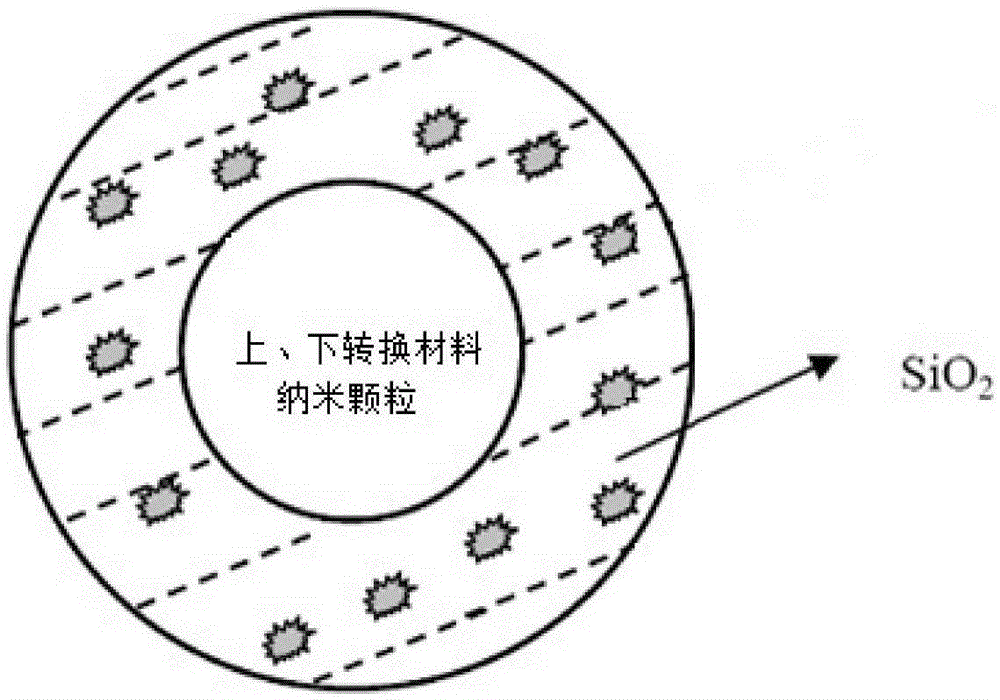

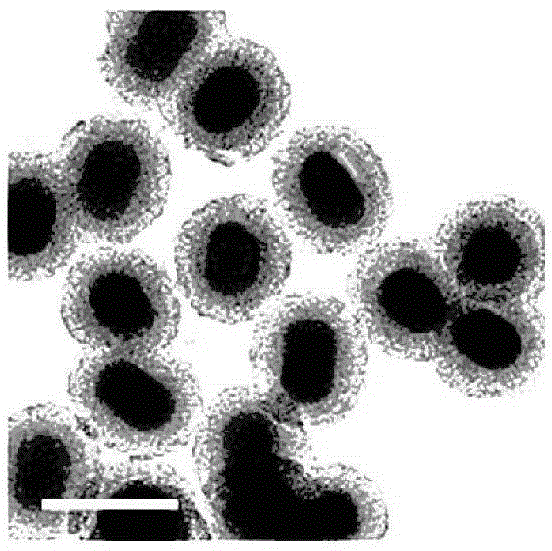

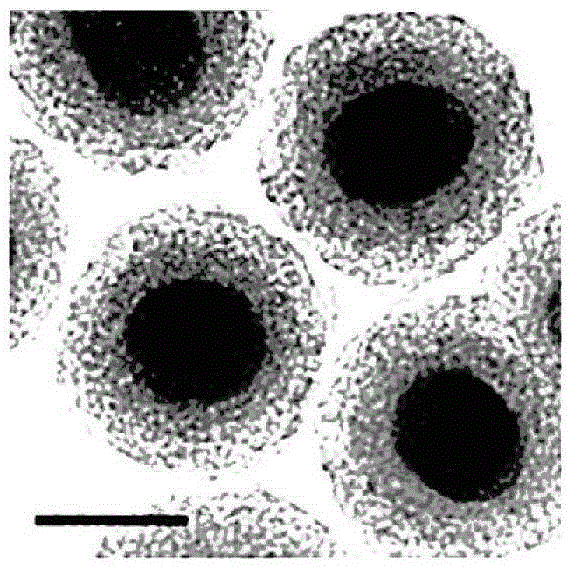

[0025] For this problem, the solution idea of the present invention is: adopt chemical method to prepare and contain up-conversion material NaYF 4 :Yb,Er + and containing the down conversion material NaYF4:Tb 3+ , Yb 3+ The silica sol is prepared by spin-coating or pulling method to contain nano-NaYF 4 : Yb, Er + and NaYF4:Tb 3+ , Yb 3+ Granular SiO 2 Thin film, this new process not only increases the number of reflections...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com