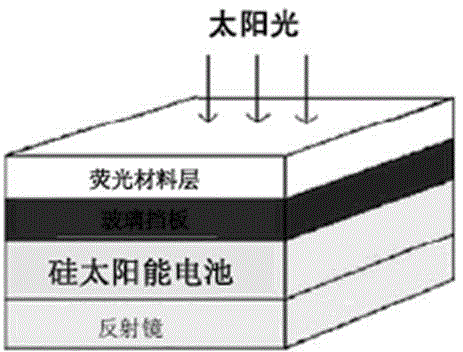

Near-infrared quantum cutting fluorescent powder capable of increasing silicon solar cell efficiency and preparation method thereof

A silicon solar cell and quantum tailoring technology, applied in chemical instruments and methods, circuits, photovoltaic power generation, etc., can solve the problems of poor mixing effect, narrow spectral range, and high intermediate loss, so as to broaden the spectral absorption range and improve conversion efficiency , The effect of low intermediate loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

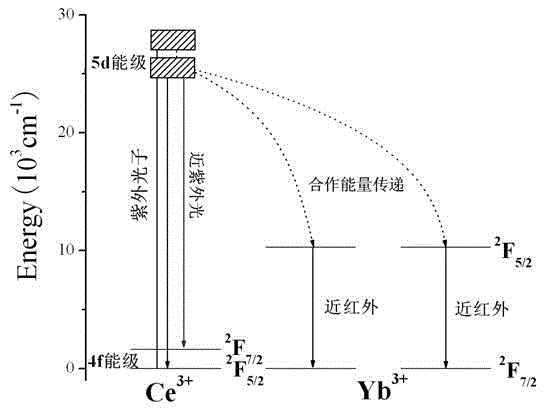

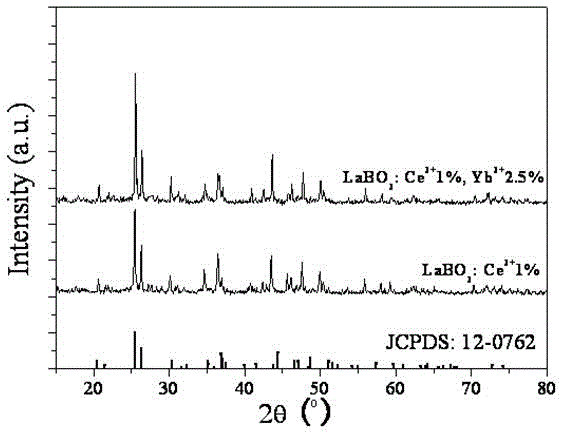

[0032] According to the chemical composition of the present invention LaBO 3 : Ce 3+ (1%), Yb 3+ (x%), respectively weigh La 2 o 3 (Analytical pure) 1.58g, HBO 3 (Analytical pure) 0.8g; Measure 100ul of 1mol / L Ce(NO 3 ) 3 solution and 200ul of 1mol / L Yb(NO 3 ) 3 solution; the La 2 o 3 、HBO 3 , Ce(NO 3 ) 3 solution and Yb(NO 3 ) 3 The solution is mixed evenly to obtain a mixture; then the mixture is dried in an oven at 80°C for 30 minutes; then the dried mixture is fully ground for 30 minutes, and the fineness of solid particles is ≤10 μm; the ground mixture is placed in a corundum crucible and placed in a high temperature box Calcined at 500°C, 900°C, and 1100°C in a type furnace for 2 hours respectively, and cooled to room temperature; the calcined sample was ground again for 10 minutes until the fineness of solid particles was ≤10 μm to obtain LaBO 3 : Ce 3+ (1%), Yb 3+ (2%) sample. Finally, the sample was tested by fluorescence spectroscopy. Figure 4 I...

Embodiment 2

[0034] According to the chemical composition of the present invention LaBO 3 : Ce 3+ (1%), Yb 3+ (x%), respectively weigh La 2 o 3 (Analytical pure) 1.56g, HBO 3 (Analytical pure) 0.8g; Measure 100ul of 1mol / L Ce(NO 3 ) 3 solution and 250ul of 1mol / L Yb(NO 3 ) 3 solution; the La 2 o 3 、HBO 3 , Ce(NO 3 ) 3 solution and Yb(NO 3 ) 3 Mix the solution evenly to obtain a mixture; put the mixture in an oven at 70°C and dry for 50 minutes; then fully grind the dried mixture for 20 minutes, and the fineness of solid particles is ≤10 μm; place the ground mixture in a corundum crucible, and put it in a high-temperature box Calcined in the furnace at 500°C, 900°C, and 1100°C for 2 hours respectively, and cooled to room temperature; the calcined sample was ground again for 20 minutes to obtain LaBO 3 : Ce 3+ (1%), Yb 3+ (2.5%) sample. Finally, the sample is tested for fluorescence spectrum, and the sample is also observed in the infrared region Yb under excitation at 33...

Embodiment 3

[0036] According to the chemical composition of the present invention LaBO 3 : Ce 3+ (1%), Yb 3+ (x%), respectively weigh La 2 o 3 (Analytical pure) 1.56g, HBO 3 (Analytical pure) 0.8g; Measure 100ul of 1mol / L Ce(NO 3 ) 3 solution and 300ul of 1mol / L Yb(NO 3 ) 3 solution; the La 2 o 3 、HBO 3 , Ce(NO 3 ) 3 solution and Yb(NO 3 ) 3 Mix the solution evenly to obtain a mixture; put the mixture in an oven at 70°C and dry for 30 minutes; then grind the dried mixture for 30 minutes, and the fineness of solid particles is ≤10 μm; place the ground mixture in a corundum crucible and put it in a high-temperature box Calcined in the furnace at 500°C, 900°C, and 1100°C for 2 hours respectively, and cooled to room temperature; the calcined sample was ground again for 10 minutes, and the solid particle fineness was ≤10 μm to obtain LaBO 3 : Ce 3+ (1%), Yb 3+ (3%) sample. Finally, the sample was tested by fluorescence spectroscopy. Figure 4 It can be seen that Ce 3+ The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com