UV-near infrared quantum cutting phosphor and preparation method thereof

A quantum tailoring, near-infrared technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of human body injury, inconvenience to popularize civilian use, etc., to achieve the effect of easy popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, rare earth ion Ce 3+ The doping effect on La(BO 2 ) 3 impact test

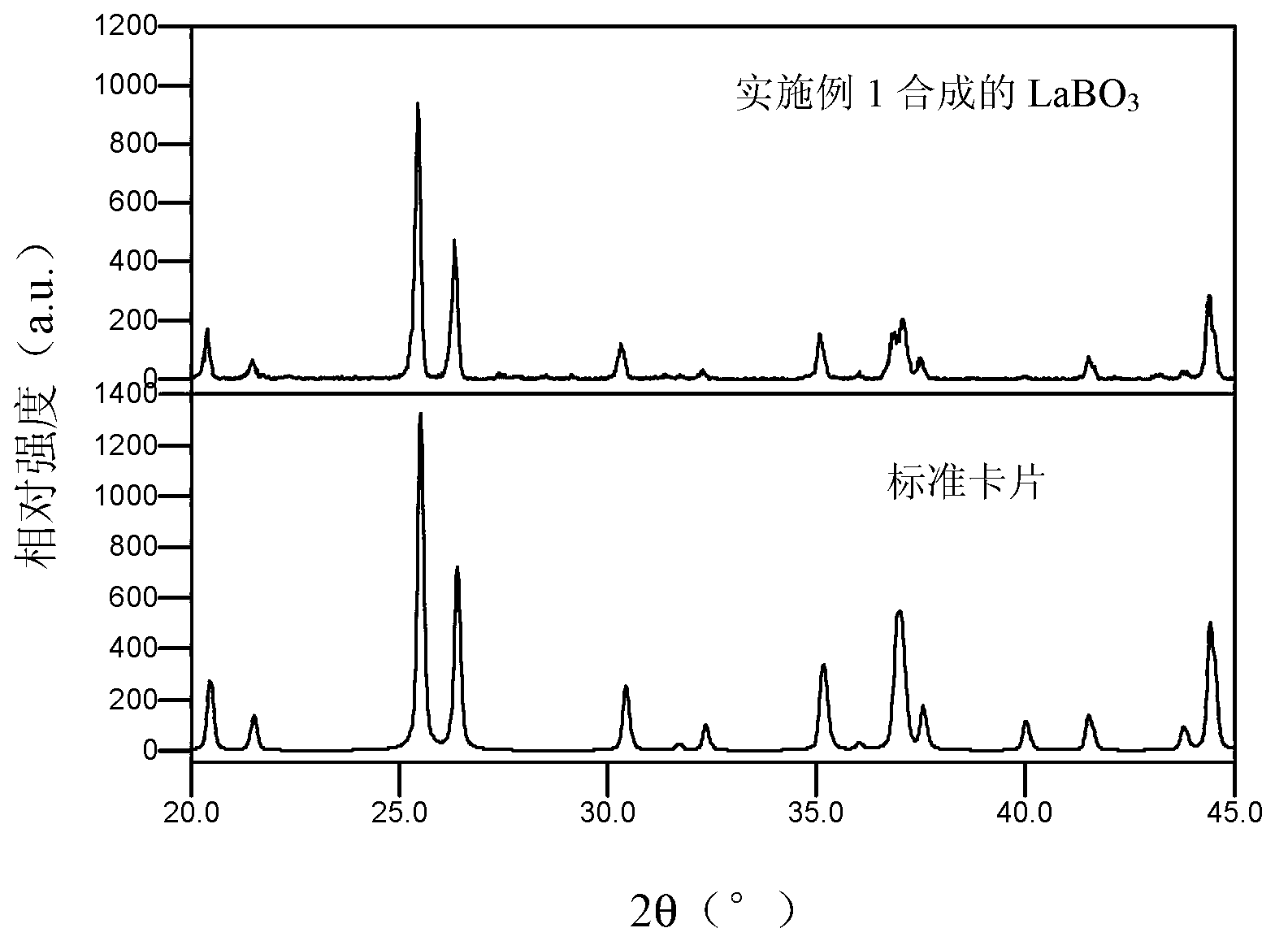

[0028] (1) After fully grinding lanthanum oxide and boric acid in an agate mortar (wherein the molar ratio of lanthanum element contained in lanthanum oxide to boric acid is 1:1), put it in a crucible under the reduction condition of C powder, first Pre-sintered at 500°C for 2 hours, and then sintered at 1100°C for 4 hours; the synthesized LaBO 3 The XRD patterns of the samples are compared with the standard cards. Such as figure 1 As shown, it can be seen from the figure that all the diffraction peaks can be indexed to LaBO 3 (LaBO 3 It is an orthorhombic crystal system, the space group is Pnma, and the unit cell parameters are Z=4), it can be known that doping does not change the crystal structure of the matrix by comparing the XRD spectra. On this basis, the doping experiment of rare earth ions was carried out.

[0029] (2) After fully grinding lanthanum oxide, cerium oxide a...

Embodiment 2

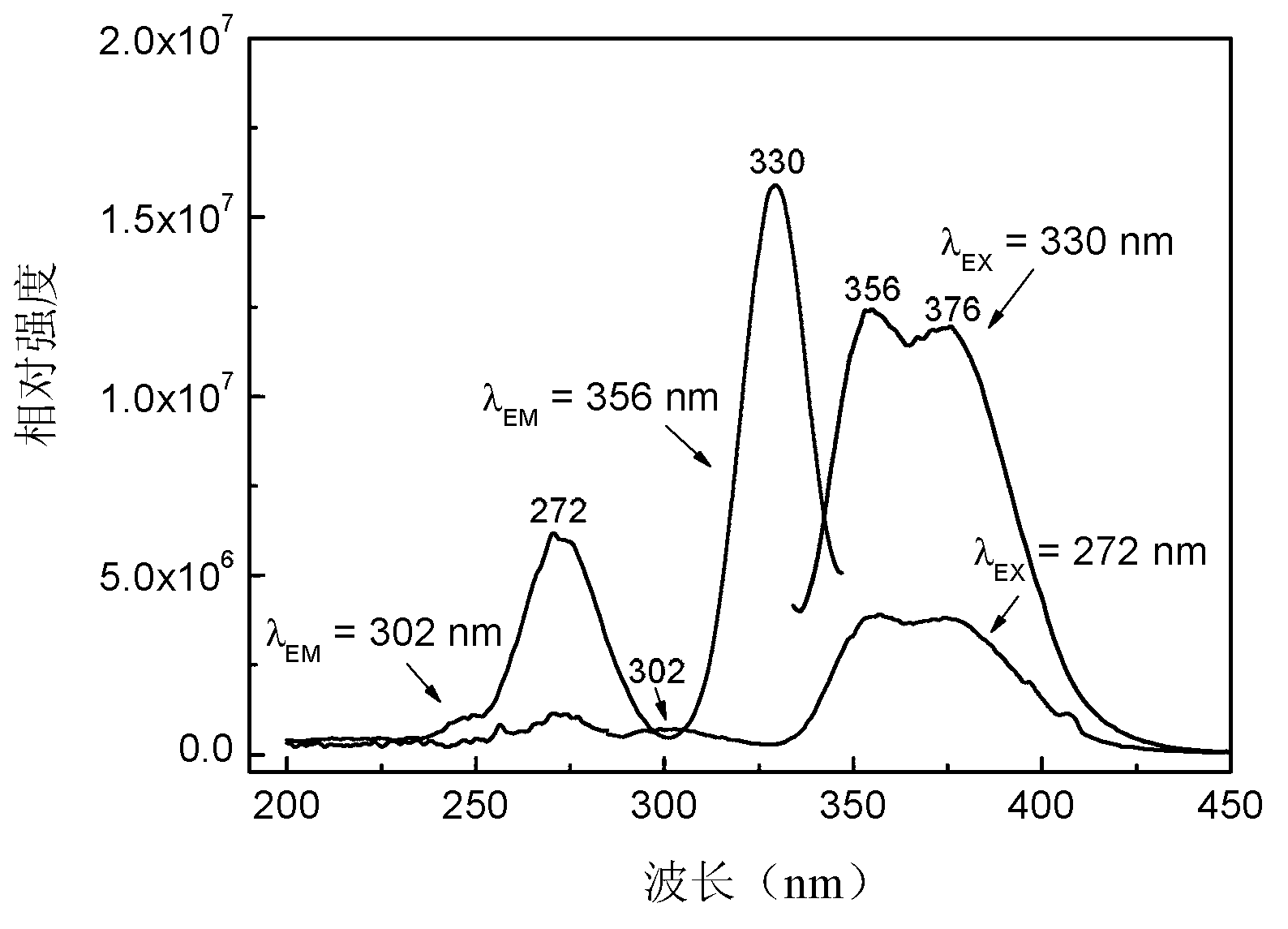

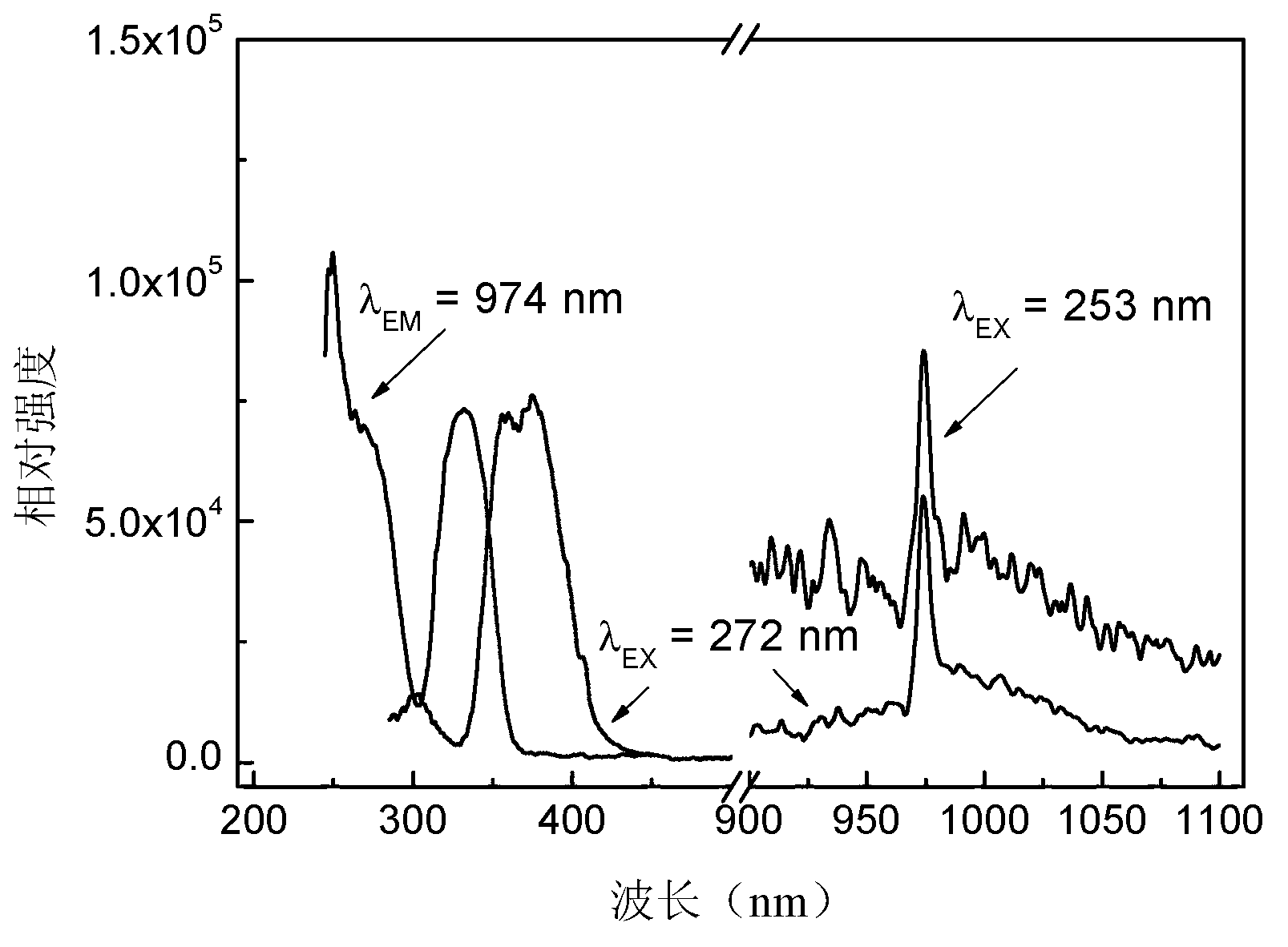

[0030] Embodiment 2, LaBO 3 : Ce 3+ , Yb 3+ Study on Luminescent Properties of Double-doped System

[0031] Using LaBO 3 As a substrate for the exploration of near-infrared luminescence, Ce 3+ The ion has broad-spectrum excitation and emission of d-f transition and effective sensitization effect, Yb 3+There are only two energy levels: 2 f 7 / 2 ground state and 2 f 5 / 2 Excited state, the significant excitation and emission wavelength is about 974nm, which requires the energy transfer of other ions to achieve photoconversion, here study Ce 3+ ions in matrix LaBO 3 The luminescence properties and Ce 3+ with Yb 3+ Fluorescence properties after co-doping.

[0032] (1)LaBO 3 : Ce 3+ Photoluminescent properties of materials

[0033] In order to better study Ce 3+ and Yb 3+ The luminescent properties of ion double doping, first study of single doped Ce 3+ Luminescent properties of ions.

[0034] figure 2 for LaBO 3 : Ce 3+ excitation and emission spectra. In thi...

Embodiment 3

[0049] Embodiment 3, fluorescent powder LaBO 3 :0.22e 3+ , 0.03Yb 3+ preparation of

[0050] Accurately weigh lanthanum oxide, cerium oxide, ytterbium oxide and boric acid and fully grind them in an agate mortar (wherein, the amount of rare earth oxides is based on the contained rare earth elements, lanthanum oxide contained in lanthanum oxide, cerium contained in cerium oxide The ratio of the sum of the amount of ytterbium contained in ytterbium oxide to the amount of boric acid is 1:1, and the ratio of the amount of cerium contained in cerium oxide to the amount of ytterbium contained in ytterbium oxide is 22:3. Put it into a crucible under the condition of C powder reduction, pre-sinter at 500°C for 3 hours, and then rise to 800°C for 6 hours to get the phosphor LaBO 3 :0.22Ce 3+ , 0.03Yb 3+ .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com