Preparation method of quantum cutting coating, solar cell, solar module and preparation method

A solar cell and quantum tailoring technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of further improvement in aesthetics and adhesion, affect the conversion efficiency of components, and immature preparation methods, etc., to achieve patterning And coloring, avoiding poor adhesion, excellent adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

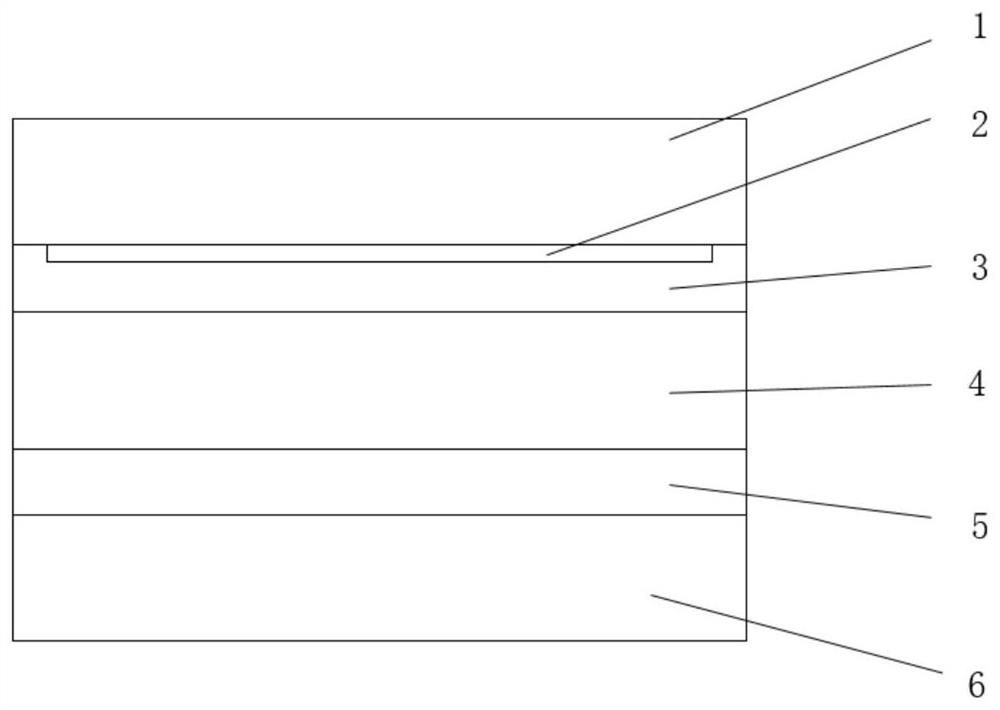

[0043] This embodiment provides a method for preparing a solar cell, and the specific preparation steps are:

[0044] First, rare earth element Yb-doped CsPbCl1.5Br1.5 perovskite quantum dots were prepared by hot injection method, the specific method is as follows: Weigh 0.8g Cs 2 CO 3 , add 30ml octadecene (ODE) and 2.5ml oleic acid, in N 2 Under the protection of the atmosphere, heat up to 150°C until completely dissolved to synthesize cesium oleate; weigh PbBr 2 (0.5 mmol), YbCl 3 (0.4mmol), add 1ml oleylamine, 1ml oleic acid, 10ml ODE, in N 2 Under atmosphere protection, raise the temperature to 160°C until the precursor is completely dissolved, then raise the temperature to 200°C and inject 1ml of the prepared cesium oleate solution, react for 10s, and cool in ice water. Yb can be obtained after centrifugal purification 3+ Perovskite quantum dots doped with rare earth elements. Next, configure the UV screen printing ink of CsPbCl1.5Br1.5:Yb (5%) according to the mas...

Embodiment 2

[0053] This embodiment provides a method for preparing a solar cell, and the specific preparation steps are:

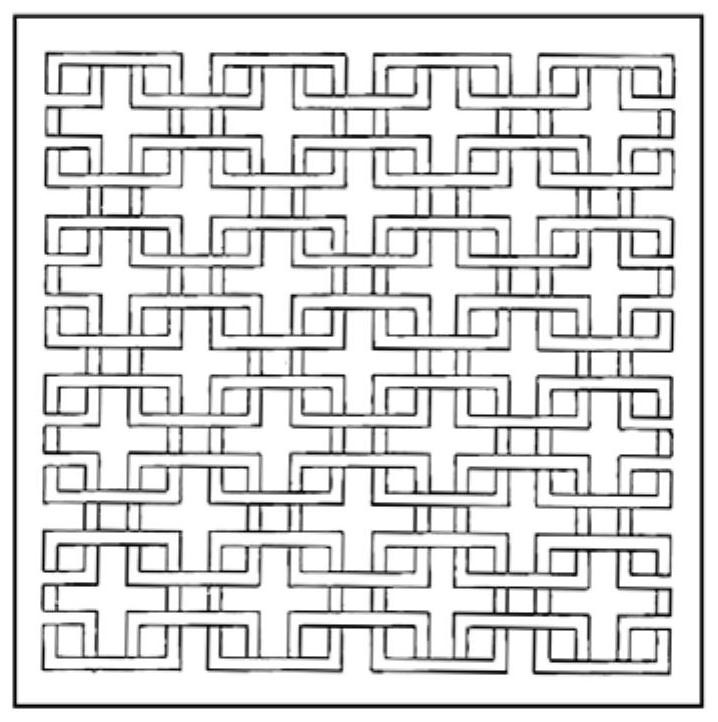

[0054] Get the CsPbCl that configures in embodiment 1 1.5 Br 1.5 : UV screen printing ink of Yb (5%) perovskite quantum dots, use 200 mesh, polyester screen with a wire diameter of 40 μm, use an 80-degree scraper to screen-print the pane pattern, and obtain a silver-white coating with a thickness of 52 μm ,Such as image 3 As shown, the dark lines are the silver-white Quantum Cut coating, and the white parts are blank. Steps such as UV light curing, encapsulation, lamination, and testing are exactly the same as those in Example 1. The coating area accounts for about 20% of the entire battery area. Due to the reduction of the quantum tailoring coating area, the battery efficiency drops to 19.5%. The adhesion is good, and its peel strength is 123.0N / cm.

Embodiment 3

[0056] This embodiment provides a method for preparing a solar cell, and the specific preparation steps are:

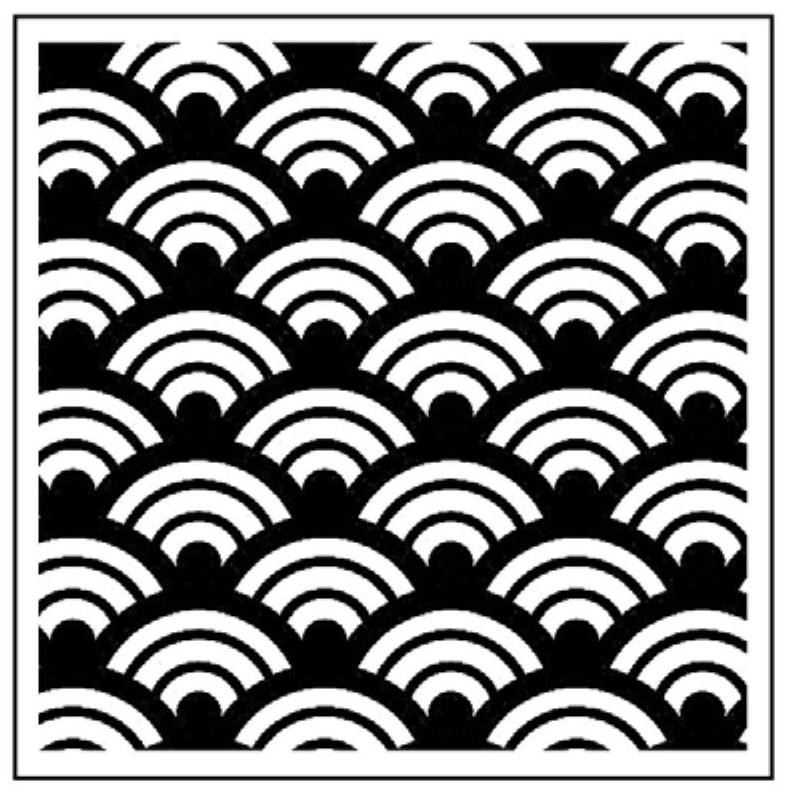

[0057] Get the CsPbCl that configures in embodiment 1 1.5 Br 1.5 : The UV screen printing ink of Yb (5%) perovskite quantum dots, with 200 orders, the polyester screen of silk diameter 40 μ m, with 80 degree scraper, screen printing pattern, obtains the silver-white coating that thickness is 59 μ m, Such as Figure 4 As shown, the dark part represents the silver-white quantum tailoring coating, and the white part represents the blank. Steps such as UV light curing, encapsulation, lamination, and testing are exactly the same as those in Example 1. The coating area accounts for about 80% of the entire battery area. Due to the increase in quantum tailoring coating area, the battery efficiency is increased to 21.9%, but the adhesion has been greatly reduced, and its peel strength is 88.0N / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com