Gold nano array substrate and preparation method thereof, and composite structure of gold nano array substrate and near-infrared quantum cutting luminescent material, and preparation method thereof

A technology of quantum tailoring and luminescent materials, which is applied in nanostructure manufacturing, nanostructure assembly, nano-optics, etc., can solve the problems of low luminous efficiency of near-infrared quantum tailoring materials, limiting the application prospects of light conversion sheets, and low spectral line intensity. Achieve the effects of improving photoelectric conversion efficiency, suitable for popularization, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the features and advantages of this patent more obvious and easy to understand, the following special examples are described in detail as follows:

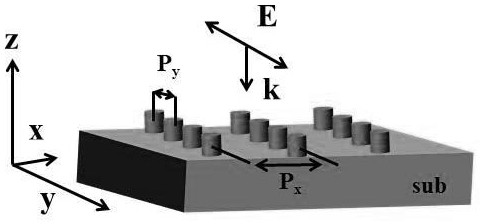

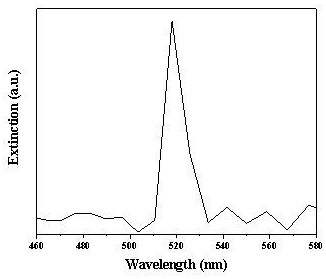

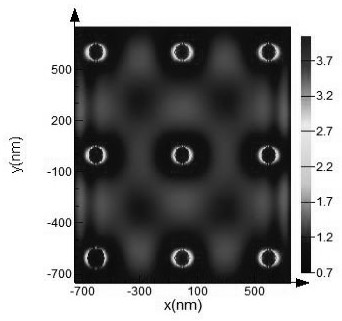

[0043] figure 1A schematic diagram of the simulation of the gold nanoarray structure is given: the extinction spectrum and electromagnetic field distribution of the gold nanoarray are simulated by FDTD software, and the structural parameters of the gold nanoarray are designed and optimized. Theoretical guidance provided by the surface lattice resonance peaks of gold nanoarray substrates.

[0044] In the extinction spectrum simulation of the gold nanoarray in this embodiment, periodic boundary conditions are introduced in the x and y directions, absorption boundary conditions are used in the z-axis direction, the substrate is set as a silicon wafer, and the diameter and height of the gold nanoarray are respectively set as 80 nm and 90 nm, period P in x and y direction x =P y = 650nm.

[0045] figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com