An automatic knife changing noodle machine

An automatic knife changer and noodle machine technology, which is applied to dough forming machinery or equipment, dough sheeting machine/rolling machine/rolling stick, dough forming and cutting equipment, etc., which can solve the problem of noodle equipment personal injury and noodle taste Insufficient muscularity, time-consuming and energy-consuming problems, etc., to achieve a clean and beautiful surface, avoid damage to the machine and personal injury, and fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

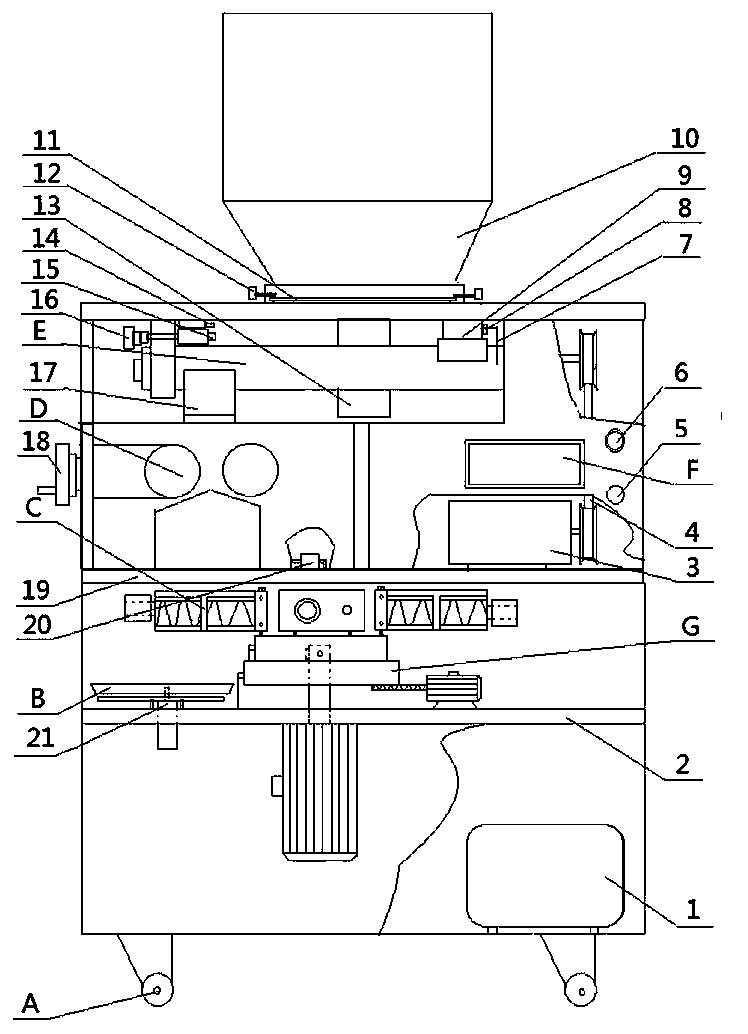

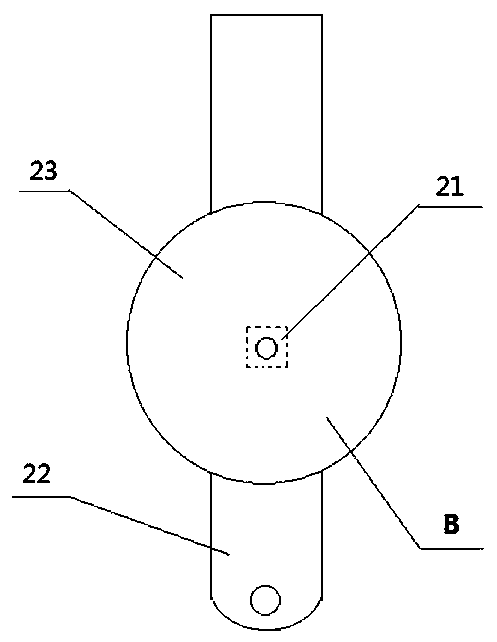

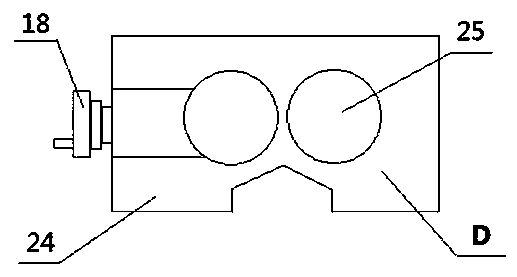

[0023] Example 1, such as Figure 1~6 As shown in the structure, an automatic knife-changing noodle machine includes a frame, a water container 1 is arranged at the bottom of the frame, a lower cabinet 2 is arranged above the water container 1, and a knife is arranged on the lower surface of the lower cabinet 2. Frame rotating motor 30, the rotating shaft of tool rest rotating motor 30 is connected with cutter rotating mechanism 33, and cutter rotating mechanism 33 below is provided with cutter separating mechanism 34 and cutter in place protection switch 31, and cutter separating mechanism 34 is connected with cutter separating and promoting motor 35, A cutter limit protection switch 32 is arranged on the side of the cutter rotating mechanism 33, and a cutter C is arranged above the cutter rotating mechanism 33; a support plate 22 is arranged on the lower cabinet 2 below the cutter C, and a connecting plate motor 21 is arranged below the support plate 22. The face plate motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com