Centrifugal humidifying dust removal filtering device

A filter device and wet dust removal technology, which is applied in the direction of combined device, separation method, and dispersed particle separation, can solve the problems of expensive filter system and increased wind resistance, and achieve the effects of convenient installation and use, avoiding wind resistance and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

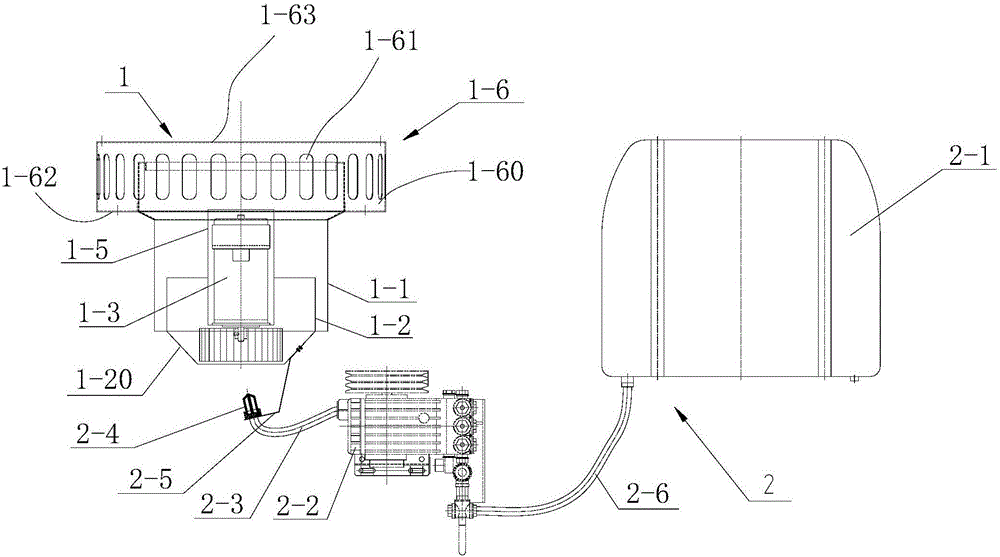

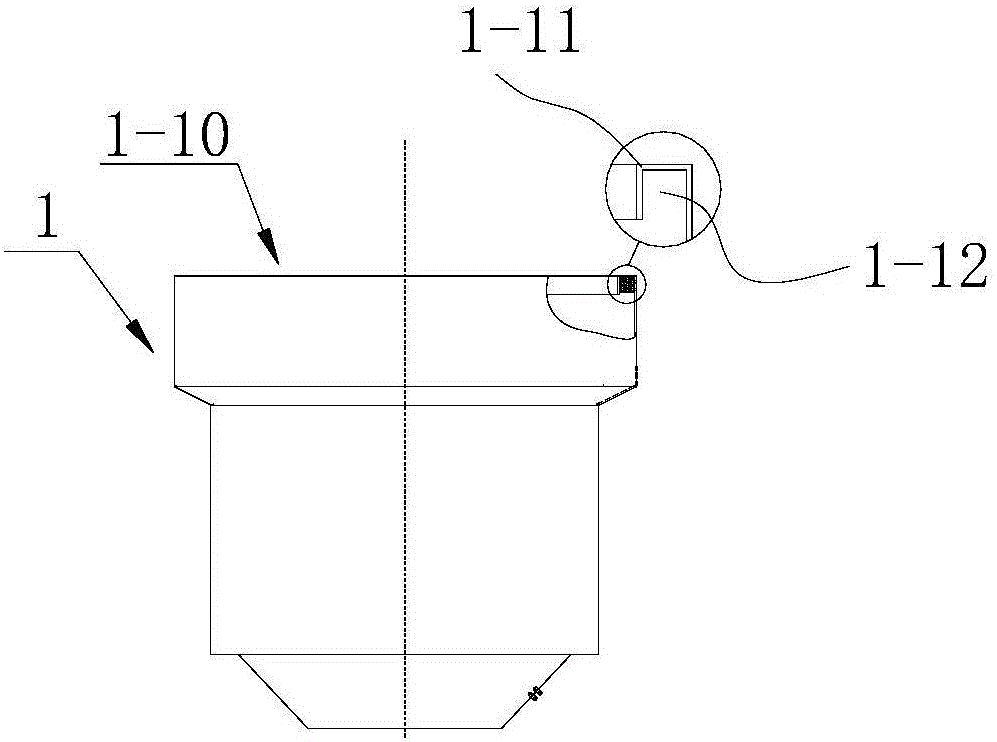

[0024] Example 1, see figure 1 , a centrifugal humidification type dust filter device, including a centrifugal dust removal cylinder 1 and an atomization humidification device 2, the centrifugal dust removal cylinder 1 is installed on the upper part of the road sweeper garbage collection box; the centrifugal dust removal cylinder 1 includes an upper end The outer cylinder 1-1 and the inner cylinder 1-2 are both open. The outer cylinder adopts a variable-diameter structure, and the diameter of the lower end is smaller than the diameter of the upper end. The effect of the enlargement is that the centrifugal force becomes smaller. The reason is that the viscosity increases, and the dust adheres to the wall of the outer cylinder due to the decrease of centrifugal force and the increase of viscosity, and then forms a fluid to flow back to the garbage collection box; the upper part of the outer cylinder is an air outlet 1-10 connected to the atmosphere; the inner cylinder The height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com