A recycling wine bottle cleaning device

A technology for cleaning devices and wine bottles, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc. It can solve the problems that the spraying device cannot meet the cleaning work, and achieve saving spraying volume, low production cost, and no need for labor The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

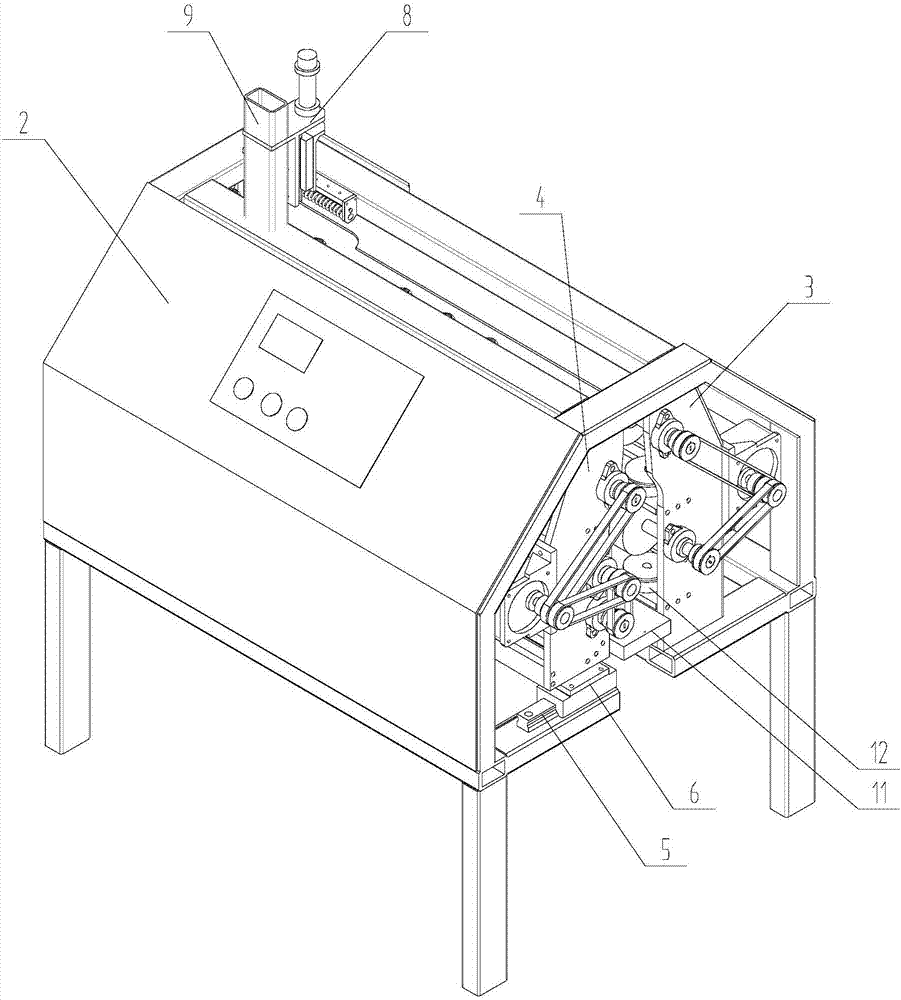

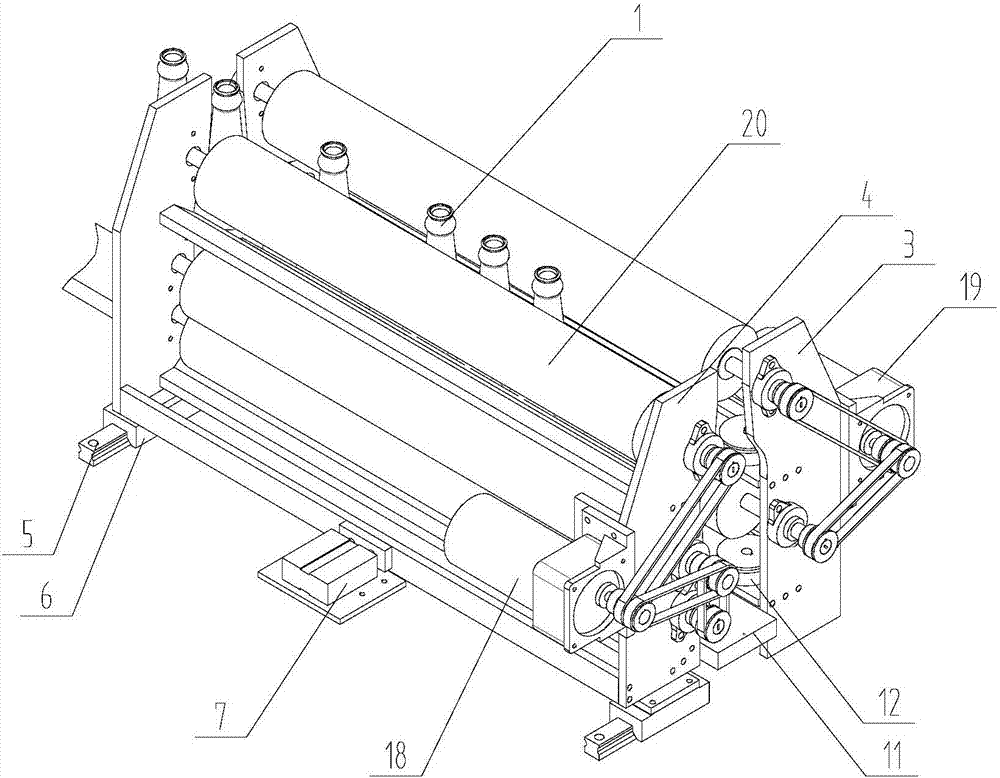

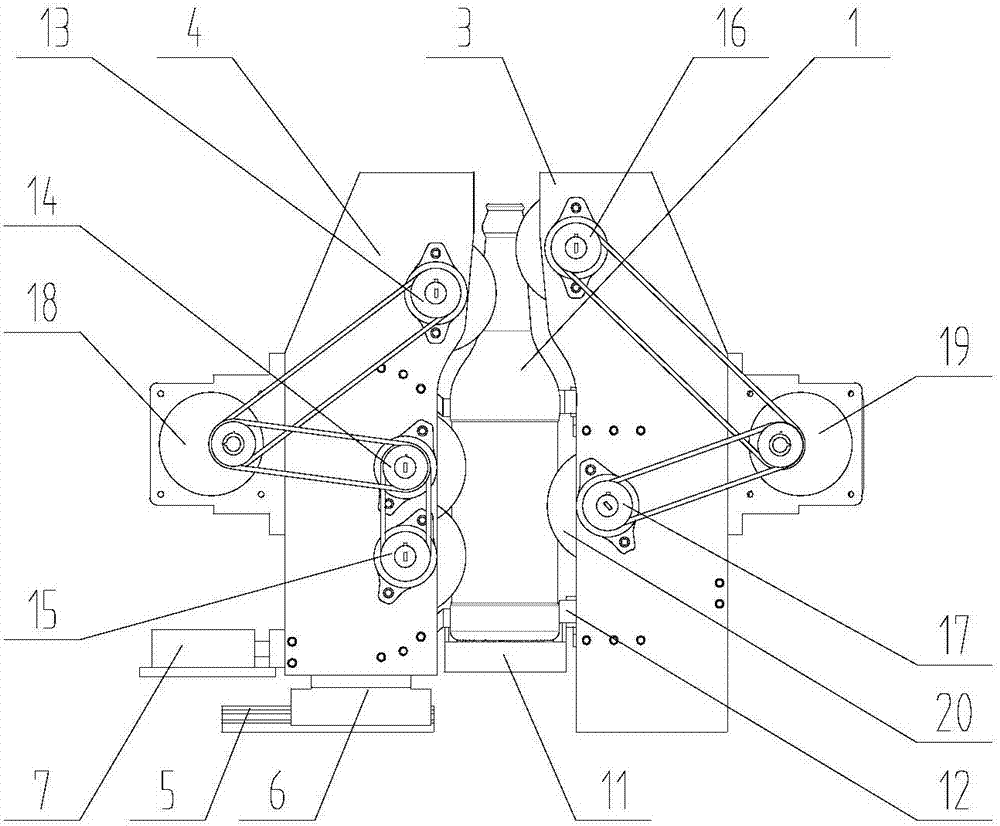

[0022] Below in conjunction with accompanying drawing, the present invention is further described:

[0023] refer to Figure 1~6As shown, a kind of recovering wine bottle cleaning device of the present invention comprises frame 2, fixed frame 3, movable frame 4, linear guide rail 5, the 3rd slide block 6, the first driving cylinder 7, antiskid rubber 10, conveyer belt 11, The conveyor belt 12, the cleaning device outside the bottle, the support seat 9 and the cleaning device 8 inside the bottle, the conveyor belt 11 used to transport the wine bottle 1 is horizontally arranged on the frame 2, and one side of the conveyor belt 11 is provided with a movable frame 4, The other side is provided with fixed mount 3, and described fixed mount 3 is fixed on the frame 2, and two third sliders 6 are fixed on the bottom of described movable frame 4, and frame 2 is provided with vertically to described conveyer belt 11 The linear guide rail 5 arranged in the direction, the movable frame 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com