a sewage processor

A technology of sewage processor and fuselage, which is applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, chemical/physical processes, etc. It can solve the problems of not being able to adapt to the disinfection treatment of sewage pools, the only direction of chlorine addition, and uneven concentration of liquid chlorine And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

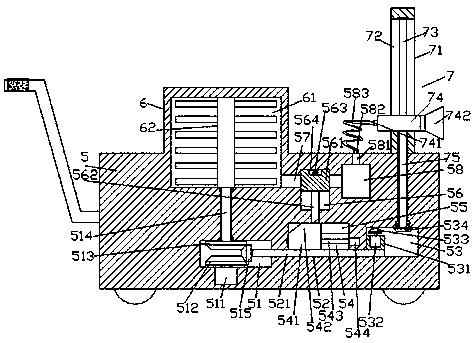

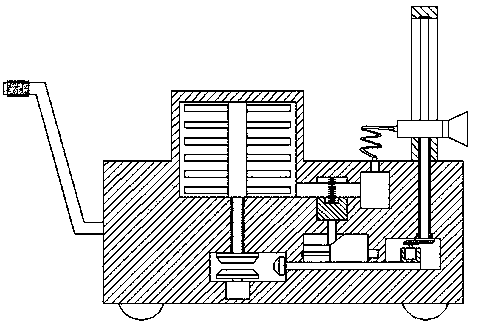

[0020] Such as Figure 1-Figure 4 As shown, a kind of sewage processor of the present invention comprises fuselage 5 and the liquid chlorine tank 6 that is arranged on the left top of described fuselage 5 and the chlorination device 7 that is arranged on the right top of described fuselage 5, so The liquid chlorine tank 6 is provided with a liquid chlorine chamber 61 extending downwards, the extension section at the bottom of the liquid chlorine chamber 61 protrudes into the fuselage 5, and a mixing component 62 is connected to the liquid chlorine chamber 61 , the fuselage 5 below the liquid chlorine chamber 61 is provided with a first chamber 51, and a conversion device is provided in the first chamber 51, and the machine body above the right side of the first chamber 51 The body 5 is provided with a guide cavity 54, and the fuselage 5 on the right side of the guide cavity 54 is provided with a second chamber 53, and the bottom of the guide cavity 54 is provided with a slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com