Self-lubricated machine tool spindle

A machine tool spindle, self-lubricating technology, applied in the field of machine tools, can solve the problems of damaged spindle, poor surface lubricity, easy impact on both ends of the spindle, etc., to achieve the effect of slowing down the impact and collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

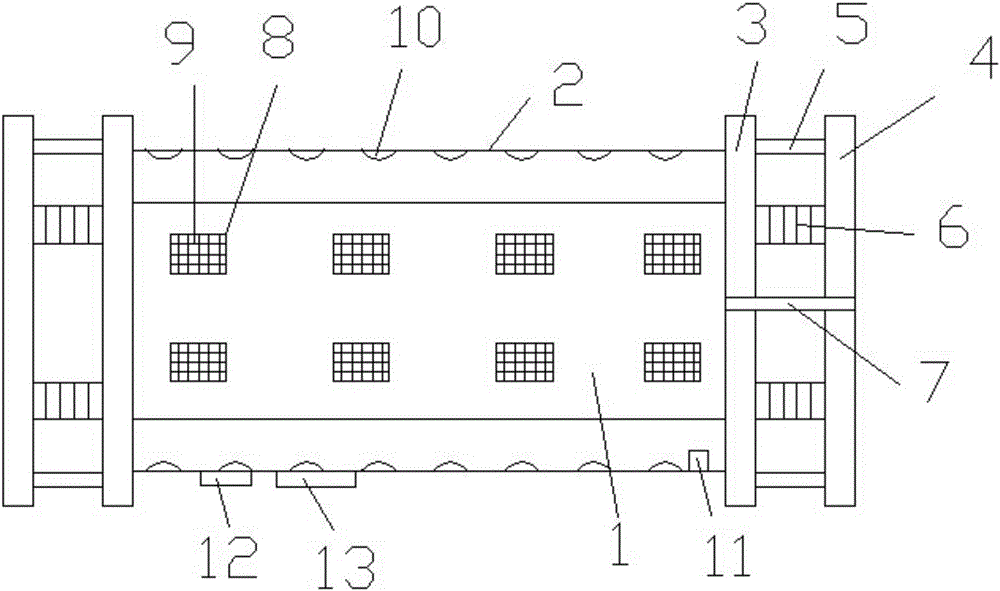

[0019] figure 1 The self-lubricating machine tool spindle shown includes a spindle shaft body 1 and a shaft sleeve 2, the spindle shaft body 1 is arranged in the shaft sleeve 2, and both ends of the shaft sleeve 2 are provided with an inner flange 3 and an outer flange 4. The inner flange 3 and the outer flange 4 are sealed and connected through a retractable sealing ring 5, and a plurality of elastic devices 6 are arranged in the sealing ring 5, and two of each elastic device 6 The ends are fixedly connected with the inner flange 3 and the outer flange 4 respectively, and an oil inlet pipe 7 is arranged between the outer flange 4 and the main shaft body 1, and several holes are arranged on the surface of the main shaft body 1 8. A piece of sponge is arranged on the inner side of each hole 8, a filter screen 9 is arranged on the outer side of the hole 8, several protrusions 10 are uniformly arranged on the inner surface of the shaft sleeve 1, and the main shaft body 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com