Thin-walled vessel head processing and fixing device and application method thereof

A fixing device and head technology, which is applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problem of incomplete fixing of the head, affecting the quality of product assembly and use, and the large ellipticity of the head port, etc. To solve the problem, achieve the effect of good head fixation, prevent processing deformation, and improve processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

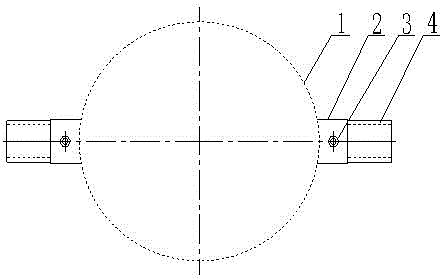

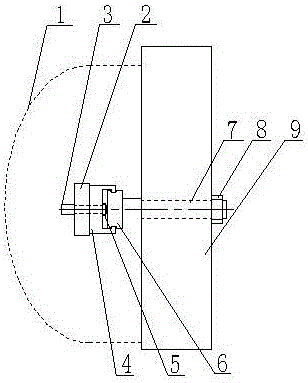

[0017] Now in conjunction with accompanying drawing, the present invention is described in detail.

[0018] A thin-walled head processing and fixing device, the structure includes head lugs 2, hexagon socket bolts 3, sliders 4, slider nuts 5, slideways 6, fixed shafts 7, and frame nuts 8; the head The lug 2 has a hole in the axial direction, which can be inserted into the slider 4; the head lug 2 and the slider 4 have matching holes in the direction perpendicular to the axis, that is, the horizontal direction; the slider 4 passes through the inner hexagon The bolt 3 is connected to the lug 2 of the head through the transverse matching hole, and the slider 4 can slide on the slideway 6 to adjust the distance between the workpiece and the machine tool; the fixed shaft 7 and the slideway 6 are welded as one.

[0019] The specific usage procedure is detailed as follows:

[0020] ① Weld the head lugs 2 to the outer walls on both sides of the thin-walled head 1, and ensure that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com