Rubber wheel packaging machine

A packaging machine and rubber wheel technology, applied in packaging, wrapping paper, shrinkage of wrapping paper, etc., can solve the problems such as stacking can not be neat, scattered, etc., to achieve the effect of beautiful packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

[0012] The directional terms mentioned in the following embodiments, such as "up, down, left, right" are only referring to the directions of the drawings, therefore, the directional terms are used for illustration and not for limiting the present invention.

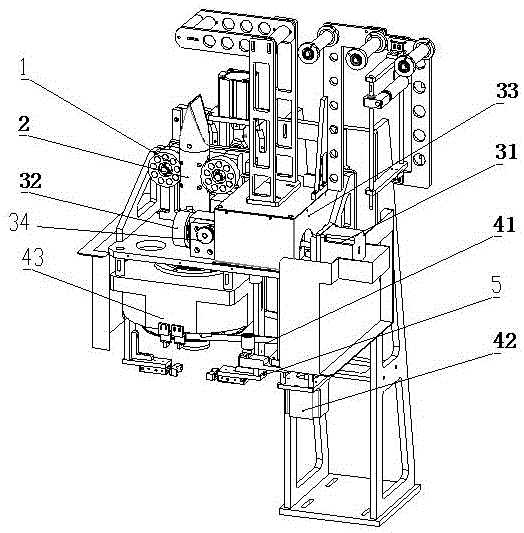

[0013] Such as figure 1 As shown, a kind of rubber wheel packaging machine equipment includes a film pressing mechanism 5 and a ring knife film cutting mechanism 4, and it also includes a film covering mechanism. The film covering mechanism is composed of a pressing steel wheel pair 1, a film covering shaft 2 and The rubber wheel drive structure consists of a film-advancing stepping motor 31, a rubber wheel 32, a universal coupling 33, a pair of gears and a pressing mechanism 34, and the film-advancing stepping motor relatively presses The tight steel wheel pair 1 moves left and right, and pushes the rubber wheel 32 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com