Film delivering and receiving device for sealing of wide-mouth barrel

A film device and film feeding technology, which is applied in the field of wide-mouth barrel sealing, can solve the problems of complicated film feeding and film collection operations, reduced sealing efficiency of wide-mouth barrels, and increased production costs, so as to achieve convenient operation and avoid tearing , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

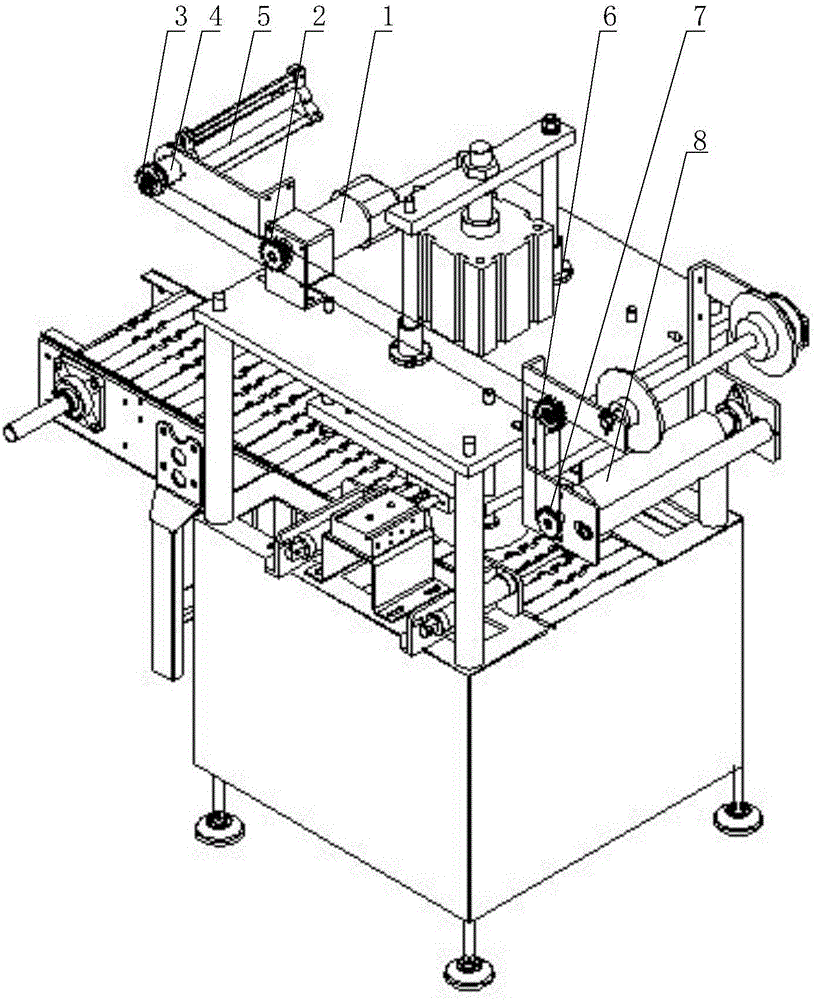

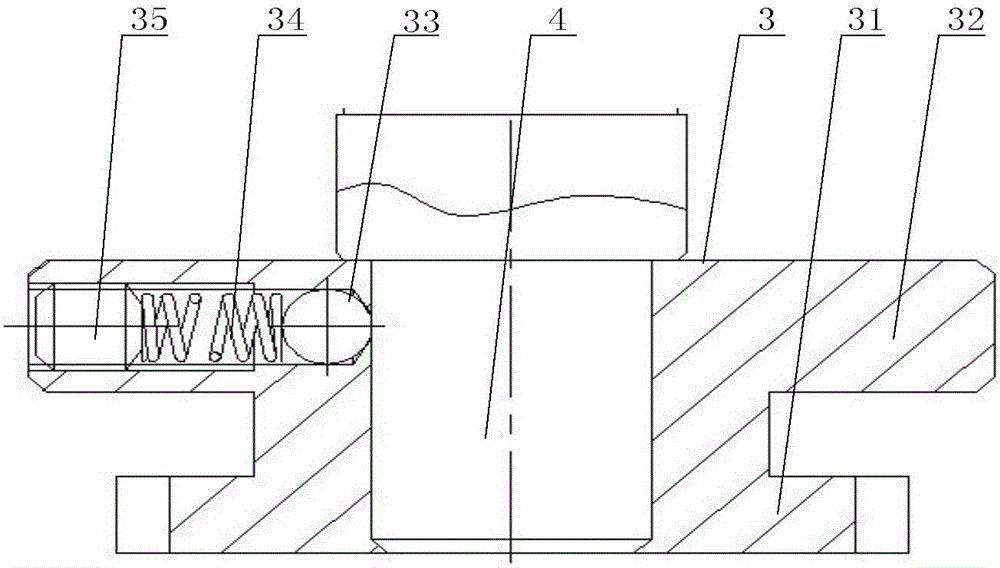

[0018] combine figure 1 , figure 2 As shown, a film feeding and collecting device for wide-mouth barrel sealing includes a motor 1, a first sprocket 2, a second sprocket 3, a film feeding shaft 4, a film feeding roller 5, a third sprocket 6, The fourth sprocket 7, film collecting roller 8.

[0019] The first sprocket 2 is connected with the motor 1 through the motor shaft, the first sprocket 2 is connected with the second sprocket 3 and the third sprocket 6 respectively through a hinge, and the third sprocket 6 is connected with the fourth sprocket 7 through a hinge. The second sprocket 3 is connected to the film feeding roller 5 through the film feeding shaft 4 , and the fourth sprocket 7 is connected to the film receiving roller 8 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com