Grab bucket

A bucket body and beam technology, which is applied in the field of wine making equipment, can solve the problems of wire rope breakage, easy material leakage, and difficulty in ensuring the closure of the grab bucket, and achieve the effects of precise angle control and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

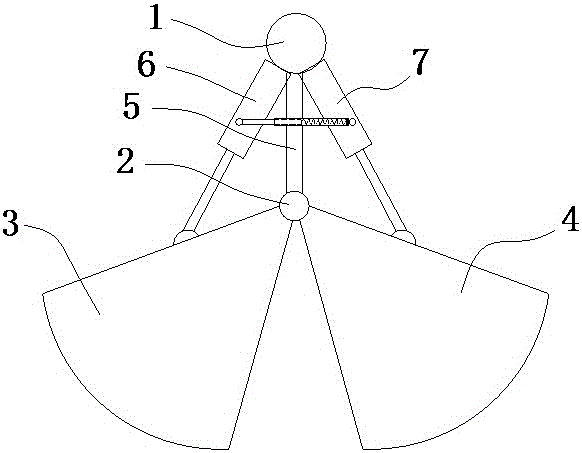

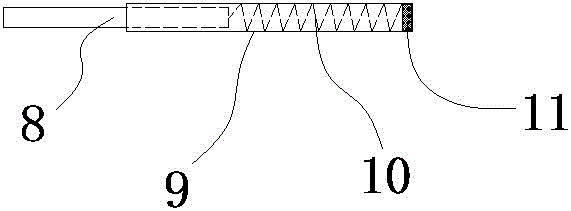

[0016] As shown in the figure, the grab bucket of this embodiment includes an upper beam 1, a lower beam 2, and a left bucket body 3 and a right bucket body 4 that are movably installed on the lower beam 2 through bearings. The upper beam 1 and the lower beam 2 pass through The rigid support 5 is connected; the key is that the grab bucket also includes a left hydraulic cylinder 6 and a right hydraulic cylinder 7, and the ends of the piston cylinders of the left hydraulic cylinder 6 and the right hydraulic cylinder 7 are respectively hinged with the bucket body on the corresponding side, so The cylinder ends of the left hydraulic cylinder 6 and the right hydraulic cylinder 7 are respectively hinged with the upper beam 1; the bottom surfaces of the left bucket body 3 and the right bucket body 4 are arc-shaped surfaces with the lower beam 2 as the center of the circle, which can reduce the size of the left bucket body. The hard collision between the bottom surface of body 3, right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com