Double-roller washing machine control method

A control method and washing machine technology, applied in the field of washing machines, can solve the problems of complicated dual-drum control and insufficient power control, achieve high heating efficiency, precise power control, and ensure stability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

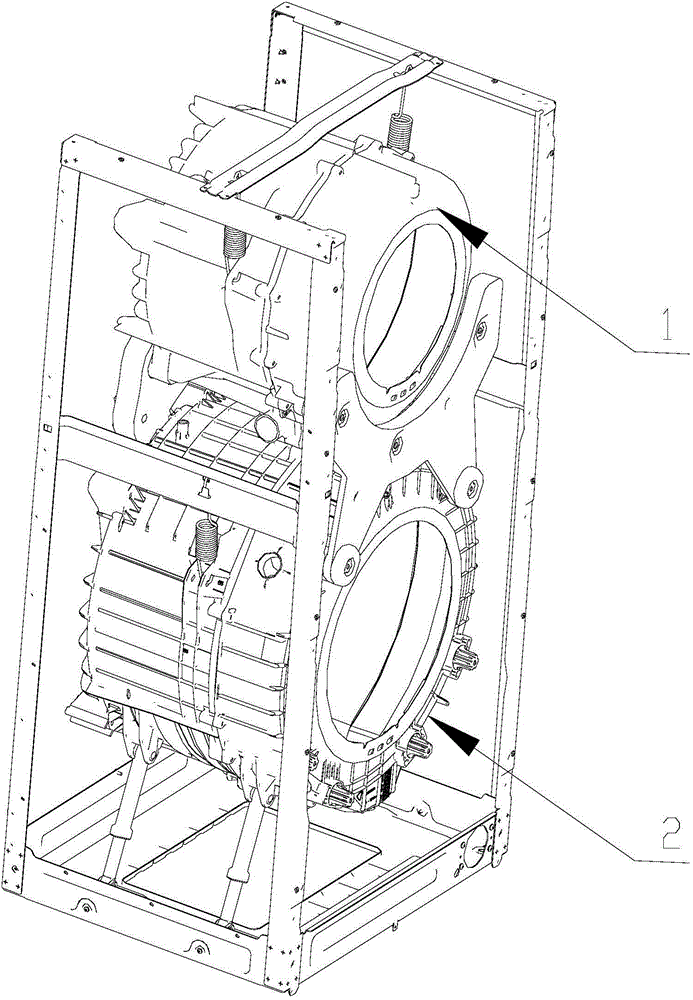

[0107] like figure 2 As shown, a double-drum washing machine in this embodiment is provided with a first washing tub 1 and a second washing tub 2 that can independently perform laundry washing steps. The first washing tub 1 and the second washing tub 2 can independently and sequentially perform a washing procedure, a rinsing procedure, and a dehydration procedure on the clothes, so as to achieve the purpose of washing the clothes.

[0108] The first washing drum 1 and the second washing drum 2 of the double-drum washing machine of this embodiment also have a first heating device and a second heating device respectively, so as to realize heating of the washing water in the first washing drum 1 and the second washing drum 2 respectively. , enhance the effect of washing.

[0109] Further, the first washing drum 1 and the second washing drum 2 described in this embodiment can also be dried separately, so that after the dehydration program, a drying program is performed to achiev...

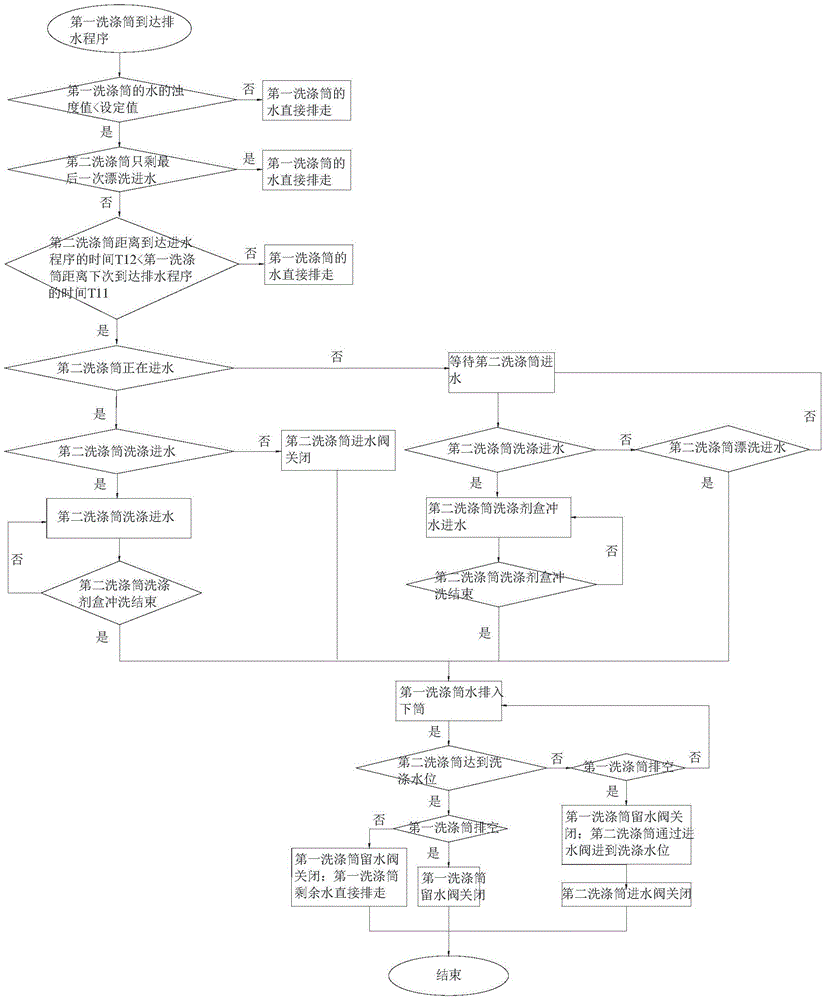

Embodiment 2

[0111] like image 3 As shown, the present embodiment uses the drainage waiting time as the judgment standard to judge whether to reuse water, and judges whether to wait for the water to be discharged to another cylinder for reuse when reaching the drainage program according to the drainage waiting time, which has a simple judgment And control logic, the control stability is higher in the actual washing program. At the same time, it realizes the full reuse of water, has high practical value, and can be more effectively popularized and applied.

[0112] When the first washing drum and the second washing drum are in working condition at the same time, the control method of water reuse is as follows:

[0113] A control method for water reuse of a multi-tubular washing machine, the multi-tubular washing machine at least includes a first washing tub and a second washing tub, and when the first washing tub and the second washing tub are in working condition at the same time, the fi...

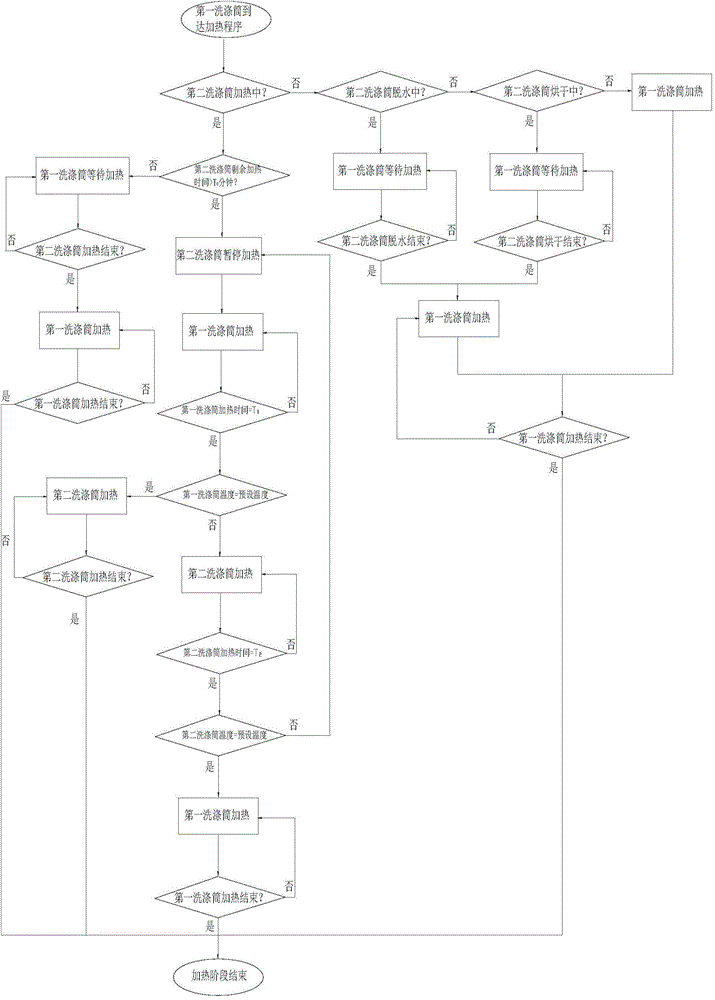

Embodiment 3

[0179] like Figure 4 As shown, the present embodiment adopts the waiting time for water inflow as the judgment standard to judge whether to reuse water, and judges whether to reuse water when waiting for another cylinder to drain water when reaching the water inflow program according to the waiting time for water inflow, which has a simple Judgment and control logic, high control stability in actual washing procedures. At the same time, it realizes the full reuse of water, has high practical value, and can be more effectively popularized and applied.

[0180] When the first washing drum and the second washing drum are in working condition at the same time, the control method of water reuse is as follows:

[0181] A control method for water recycling of a multi-tubular washing machine, the multi-tubular washing machine at least includes a first washing tub and a second washing tub, and when the first washing tub and the second washing tub are in working state at the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com