A frame barrel wharf structure and its manufacturing method

A wharf and frame barrel technology, which is applied in the field of frame barrel wharf structure and manufacturing, can solve problems such as project investment waste, and achieve the effects of reducing project cost, saving pile foundation costs, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

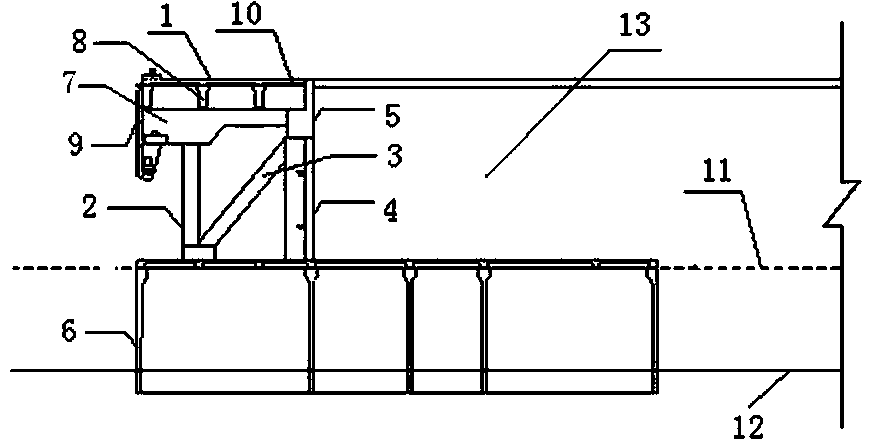

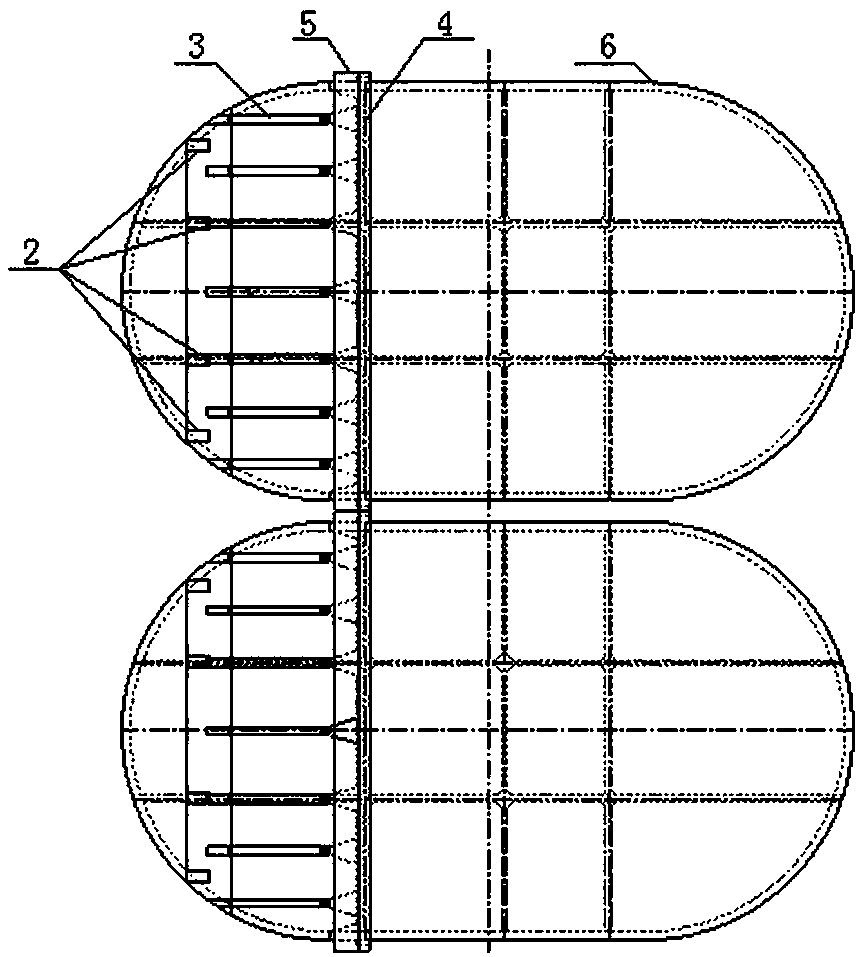

[0031] Such as figure 1 As shown, a frame barrel wharf structure is composed of an upper wharf structure 1, a basic barrel body 6, a frame column 2, a diagonal brace 3, a retaining wall 4 and an upper guide beam 5; the upper wharf structure 1 is composed of Composed of beams 7, longitudinal beams 8 and wharf panels 10, longitudinal beams 8 are arranged above the beams 7, and wharf panels 10 are arranged above the longitudinal beams 8; the upper wharf structure 1 mainly bears the berthing load and transmits it to the foundation barrel 6. Realize the function of the wharf; the upper guide beam 5 connects the upper wharf structure 1 with the retaining wall 4, and transfers the load of the wharf to the retaining wall 4 and the rear soil 13, and also has the function of retaining soil; the frame column 2 The upper end is connected to the beam 7, and the lower end of the frame column 2 is connected to the foundation barrel body 6, and the frame column 2 transfers the load of the upp...

Embodiment 2

[0033] Such as Figure 1-2 As shown, a method for manufacturing a frame barrel wharf structure, the frame barrel wharf structure is composed of an upper wharf structure 1, a base barrel body 6, a frame column 2, a diagonal brace 3, a retaining wall 4 and an upper guide beam 5; Its manufacturing method is as follows:

[0034] 1) Prefabricated foundation barrel 6, frame column 2, diagonal brace 3, retaining wall 4;

[0035] 2) Install the foundation barrel 6; install the frame column 2 and the retaining wall 4 above the foundation barrel 6, and the diagonal brace 3 connects the frame column 2 and the retaining wall 4;

[0036] 3) cast-in-place upper guide beam 5;

[0037] 4) Foundation treatment of land reclamation and soil behind dredging reclamation;

[0038] 5) The beam 7 of the cast-in-place upper wharf structure 1;

[0039] 6) installing the longitudinal beam 8 and the cast-in-place node;

[0040] 7) Installation of berthing components and fender attachments;

[0041]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com