Concrete bearing platform used for steel-structure stand column

A technology for concrete and steel structures, applied in basic structure engineering, building structure, construction, etc., can solve the problems of increasing construction difficulty of concrete caps, difficulty in installing holes for column chassis, and time-consuming, saving manpower and construction process. Fast, load-bearing strength-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

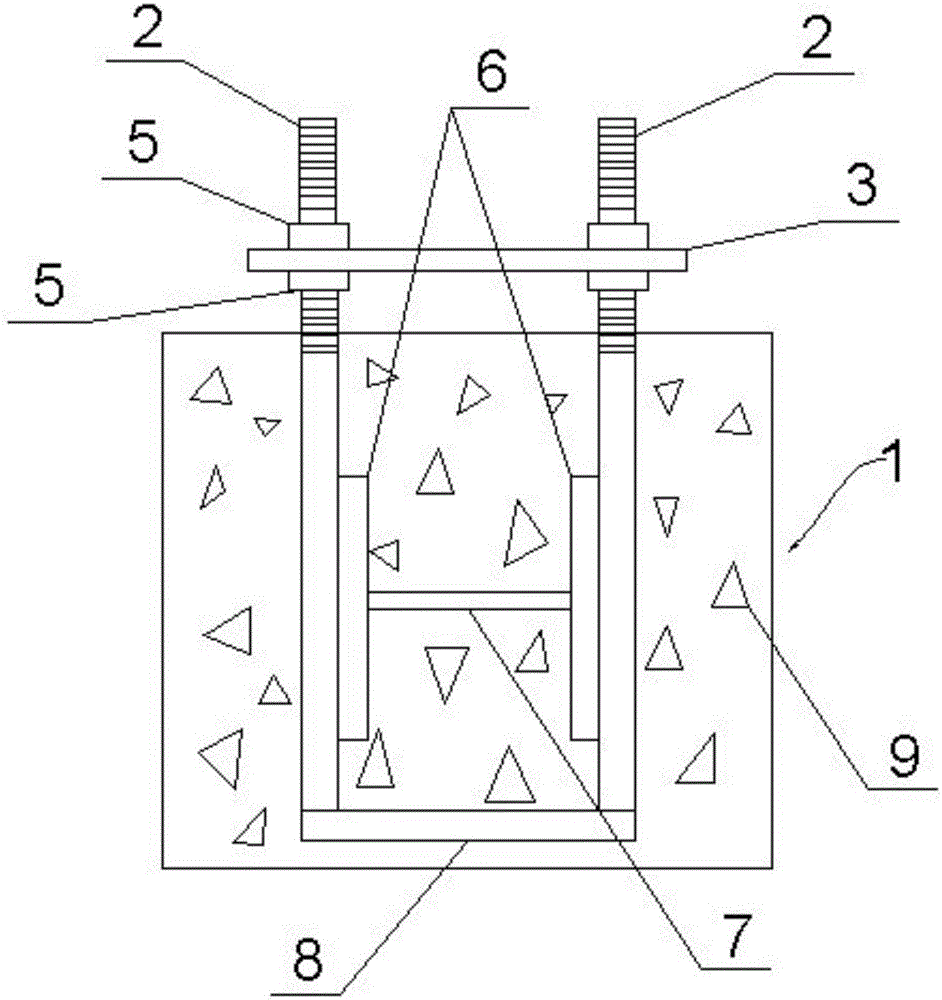

[0012] The present invention will be further described below in conjunction with accompanying drawing.

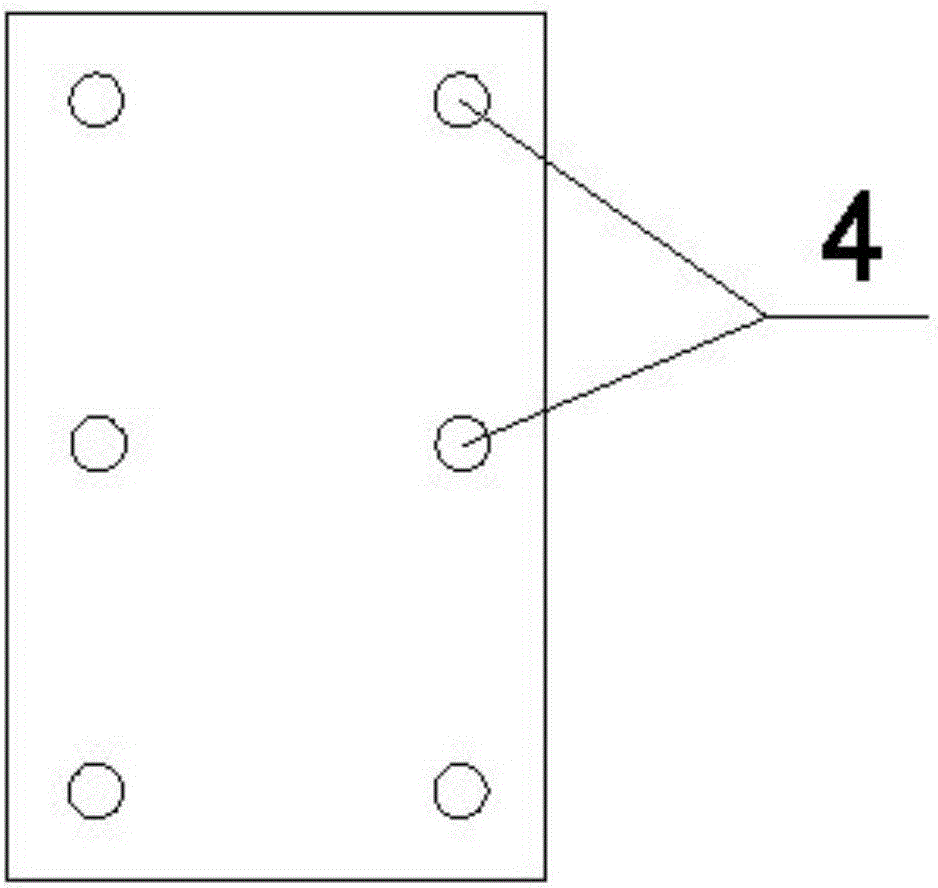

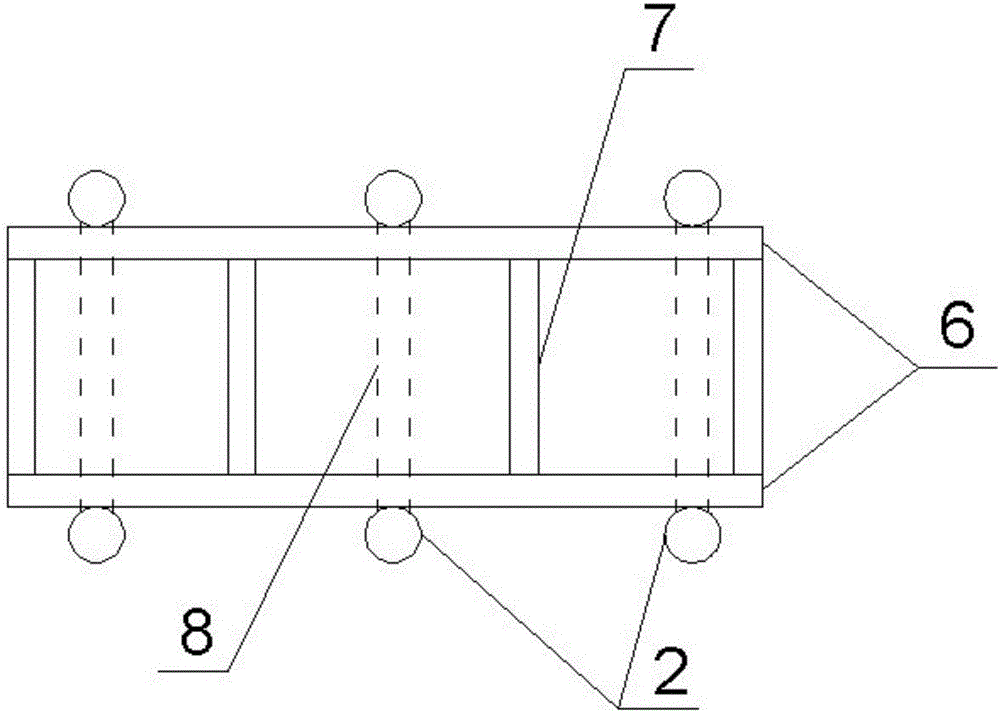

[0013] Such as Figure 1 to Figure 3 As shown, a concrete cap for a steel structure column includes a cap body 1, two rows of screw rods 2 evenly distributed along the length direction of the cap body 1, a horizontal steel sleeve plate 3, and two vertically arranged Longitudinal pressure bearing plate 6, the upper end of the screw rod 2 protrudes from the top surface of the platform body 1, and its lower part is anchored in the platform body 1, the steel sleeve plate 3 is provided with a plurality of positioning holes 4, each positioning The holes 4 are in one-to-one correspondence with the screw rods 2 of the platform body 1, and each screw rod 2 passes through the corresponding positioning hole 4 on the steel sleeve plate 3. The nut 5, the top surface and the bottom surface of the steel sleeve plate 3 abut against the adjusting nuts 5 on both sides respectively, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com