Movable arch form structure and installation method therefor

A movable, arched formwork technology, which is applied in building construction, formwork/formwork/work frame, construction components on-site preparation, etc., can solve the problems such as inconvenient removal, and achieve good mobility, convenient disassembly and maintenance low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

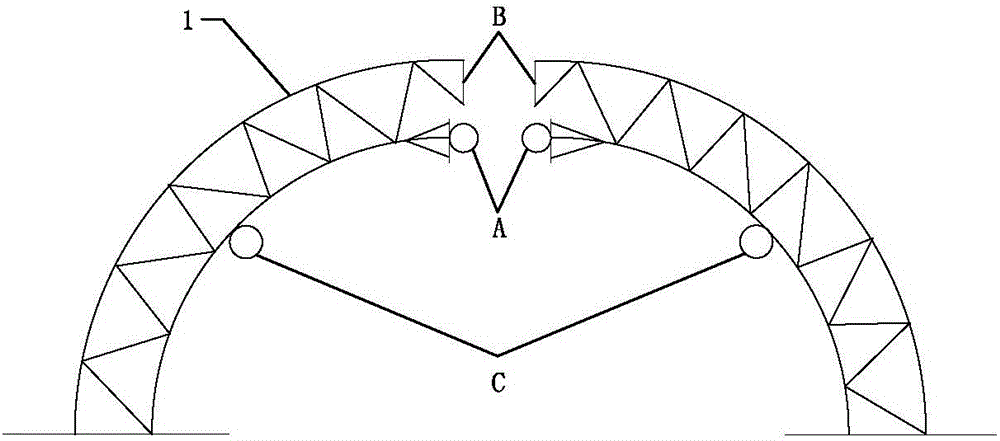

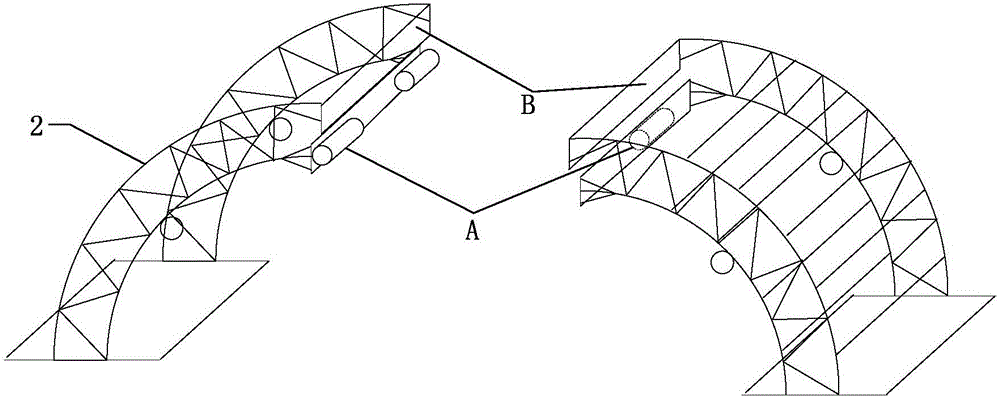

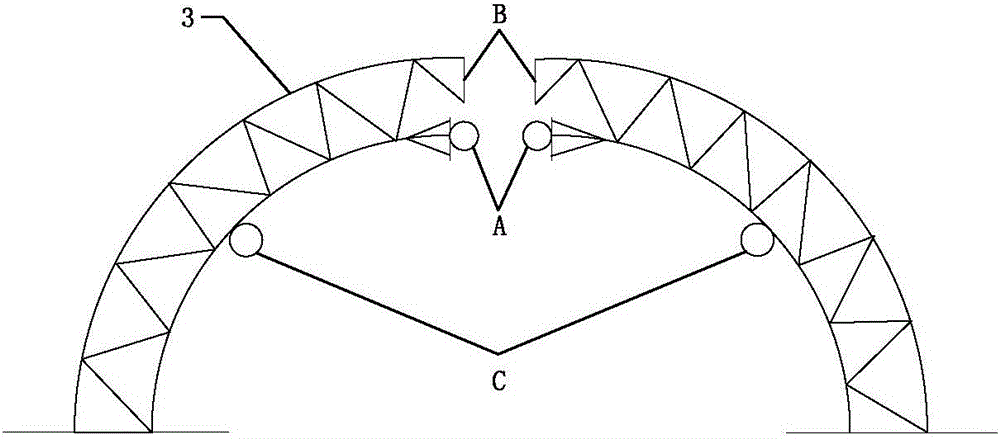

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 A movable arch form structure is shown, including: a front arch form, a middle arch form, a rear arch form and a formwork arranged between two adjacent arch forms for forming a pouring groove;

[0033] The front arch mold 1, the middle arch mold 2 and the rear arch mold 3 are all semicircular arc arch molds, and are all assembled by two 1 / 4 arc half molds;

[0034] Among them, each 1 / 4 arc-shaped half-mold is composed of a steel inner ring, a steel outer ring, and a number of reinforcing steel ribs welded between the inner ring and the outer ring; every two 1 / 4 arc-shaped half-molds are It is top butt joint assembly, and the top of each 1 / 4 arc half-mold is provided with a longitudinally arranged butt plate B, and the bottom of the butt plate B is provided with a butt sleeve A, and the butt joint at the top of each 1 / 4 arc half-mold After the steel plate B is bonded, the through holes of the two part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com