Centrifugal dehydration mechanism for cleaned straw

A cleaning and centrifugal technology, which is applied in the direction of drying solid materials, drying solid materials without heating, lighting and heating equipment, etc., can solve the problems of slow dehydration of straw, achieve fast dehydration speed, and shorten the time of dehydration and drying , The effect of speeding up the application production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] Example 1

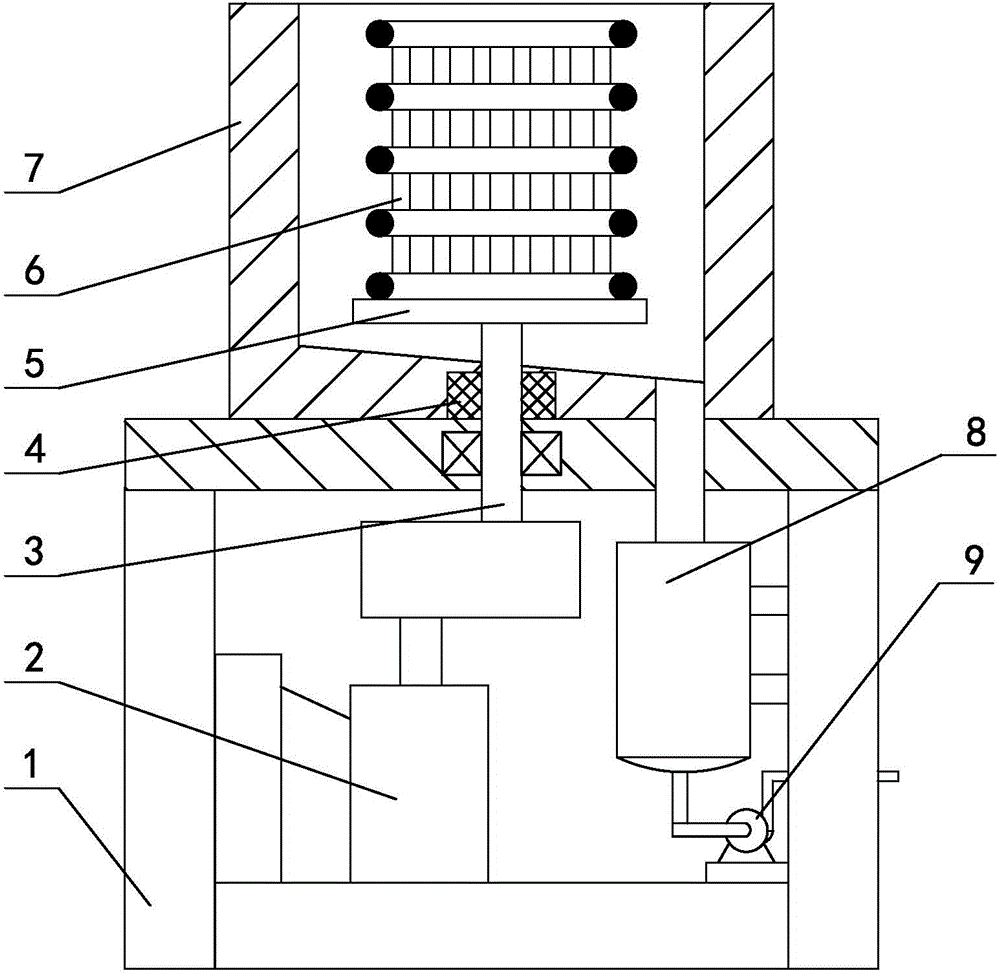

[0022] like figure 1 As shown in the figure, the centrifugal dewatering mechanism after straw cleaning includes a dewatering bucket 6 and a workbench 1. The workbench 1 is equipped with a moisture collection tank 7 for collecting the dehydrated straws uniformly, and a drainage line is arranged at the bottom of the moisture collection tank 7. A rotatable rotary disk 5 is arranged in the moisture collection tank 7, the dehydration bucket 6 is installed on the rotary disk 5, and a rotating shaft 3 is vertically fixed at the bottom of the rotary disk 5, and the corresponding rotating shaft 3 is respectively at the bottom of the moisture collection tank 7 and the working The table 1 is provided with a through hole for the rotating shaft 3 to pass through independently. The rotating shaft 3 is connected with the worktable 1 through a bearing in a mutual rotational fit. The lower part of the drainage pipeline is provided with a collection tank 8 and a delivery wat...

Example Embodiment

[0025] Embodiment 2

[0026] On the basis of the first embodiment, the sealing member 4 is a packing seal; the power mechanism is a hydraulic motor; the inclination angle of the inclined surface is changed to 20 degrees. Others are the same as the first embodiment.

Example Embodiment

[0027] Embodiment 3

[0028] On the basis of the first embodiment, the power mechanism is a pneumatic motor; the inclination angle of the inclined surface is changed to 15 degrees. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap