A four-corner error calibration device for a load cell

A technology of weighing sensor and four-corner error, which is applied in the direction of weighing equipment testing/calibration, etc., can solve the problems of low testing accuracy and efficiency, high labor intensity of workers, and poor loading stability, and achieve easy operation, high integration, and guaranteed The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

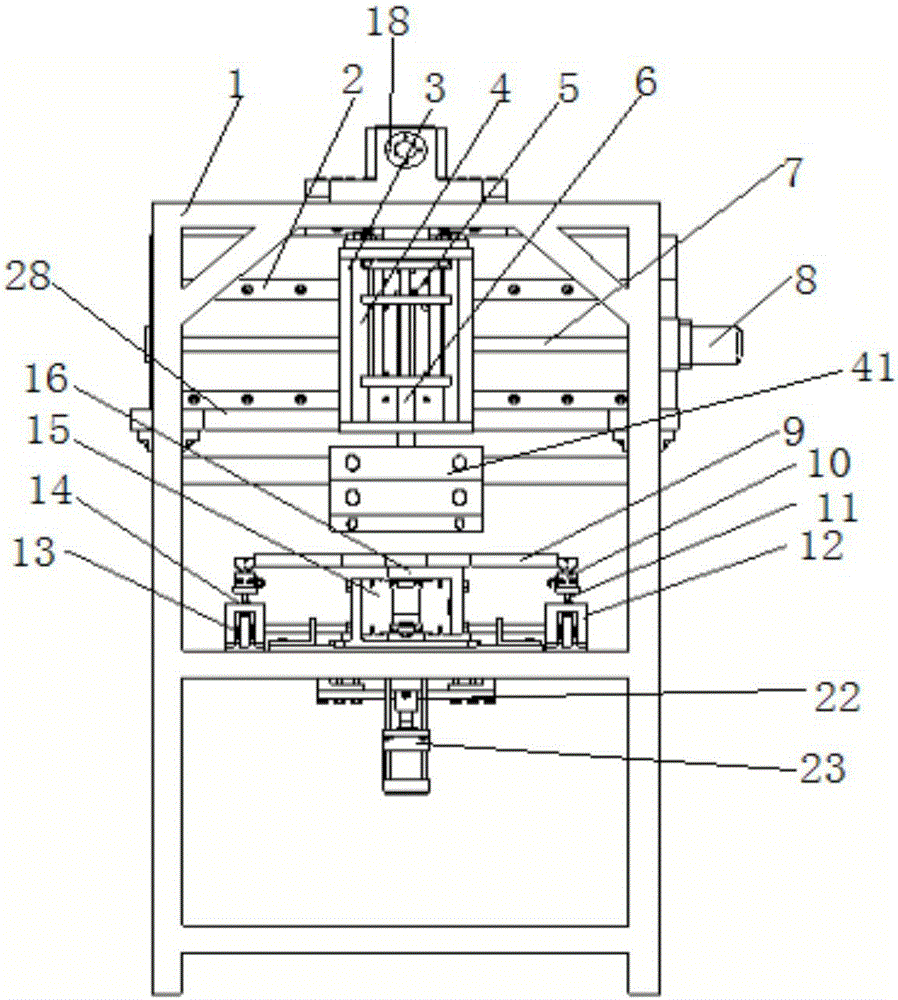

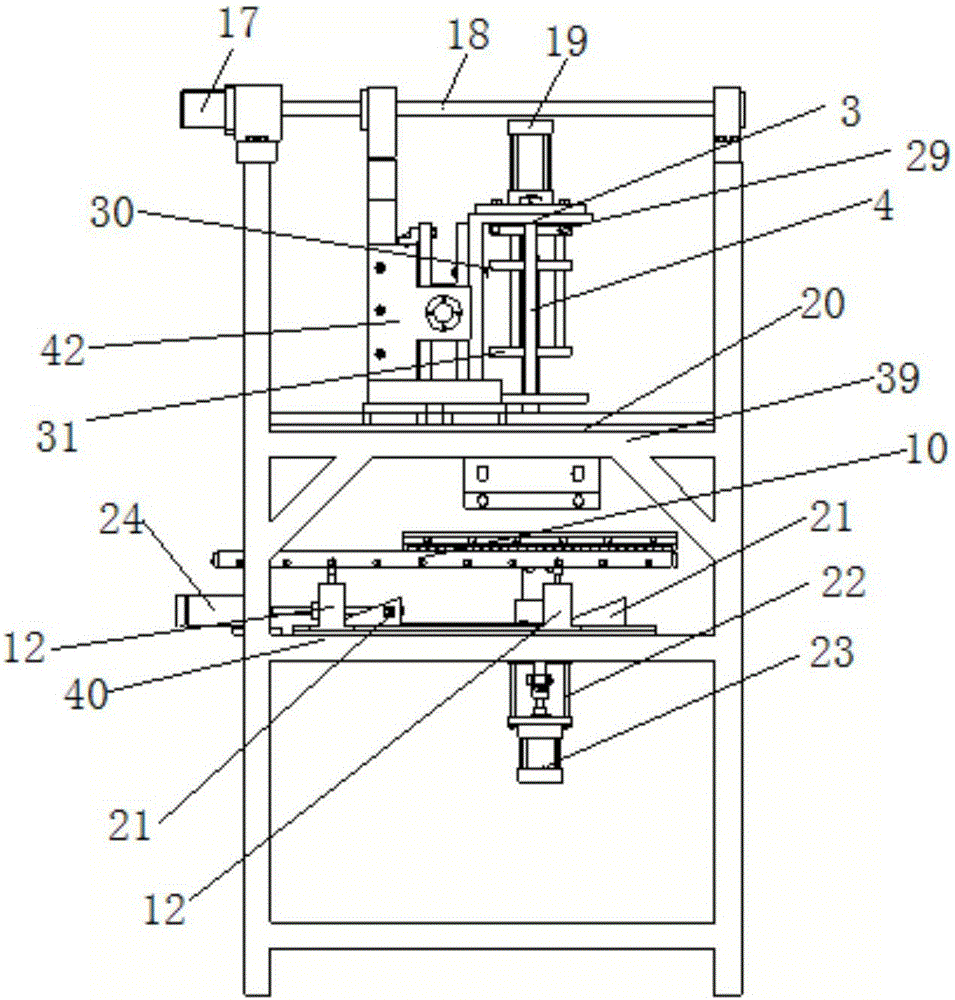

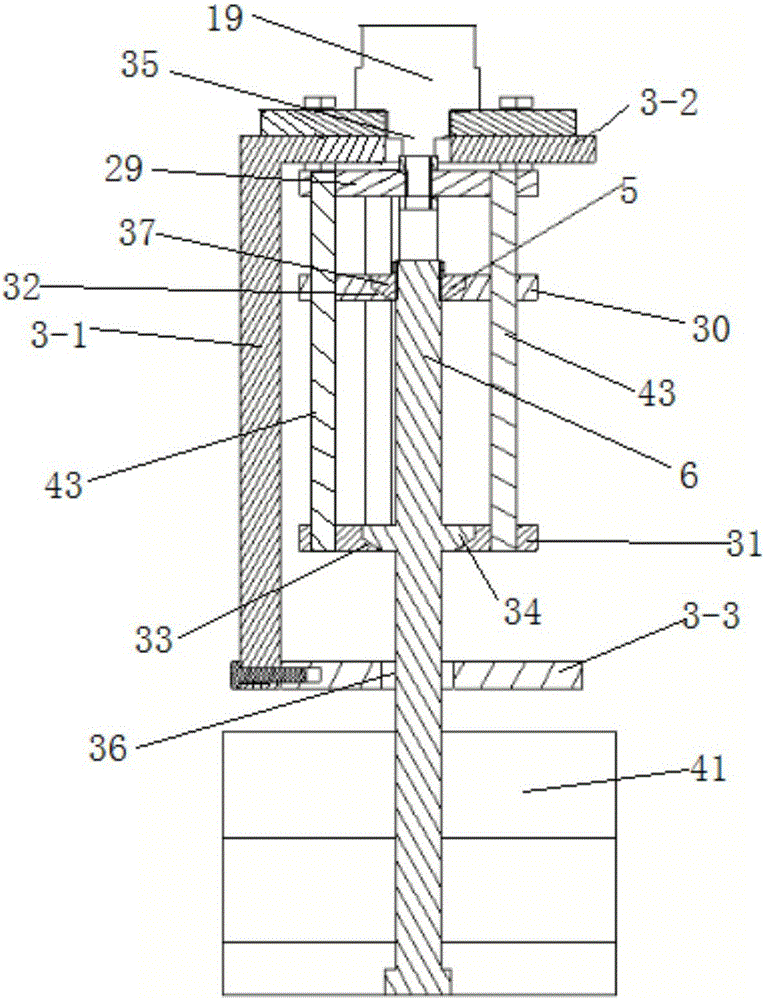

[0023] The present invention is a weighing sensor four-corner error calibration device, the structure is as follows figure 1 , 2 As shown, including the frame 1, the inside of the frame 1 is sequentially provided with a platform A39 and a platform B40 parallel to each other from top to bottom, the two ends of the platform A39 are respectively provided with radial guide rails A20 along the horizontal direction, and the radial guide rail A20 is provided with There is a moving mechanism for driving the movement of the weight group support seat 3, the upper end of the weight group support seat 3 is provided with a first cylinder 19 moving in the vertical direction, and the bottom of the first cylinder 19 is provided with a cylinder for driving the movement of the weight rod 6 The bracket, the bracket is located in the weight group support seat 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com