Fixture transfer plate for stern room vibration test

A technology of vibration test and adapter plate, applied in the field of adapter plate, can solve the problems such as the increase of the cost of the vibration test of the tail cabin, and achieve the effect of reducing the clamping and correction time, increasing the number of bolts, and ensuring the firmness and stability of the connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

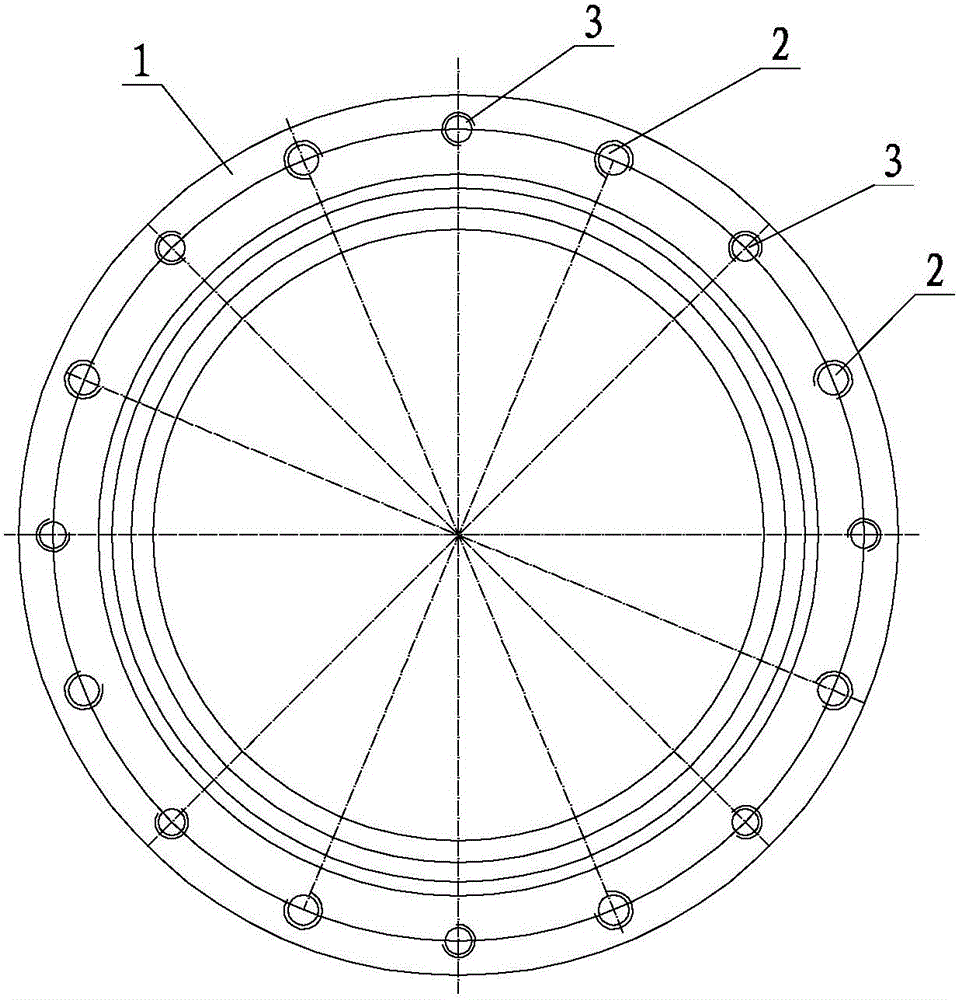

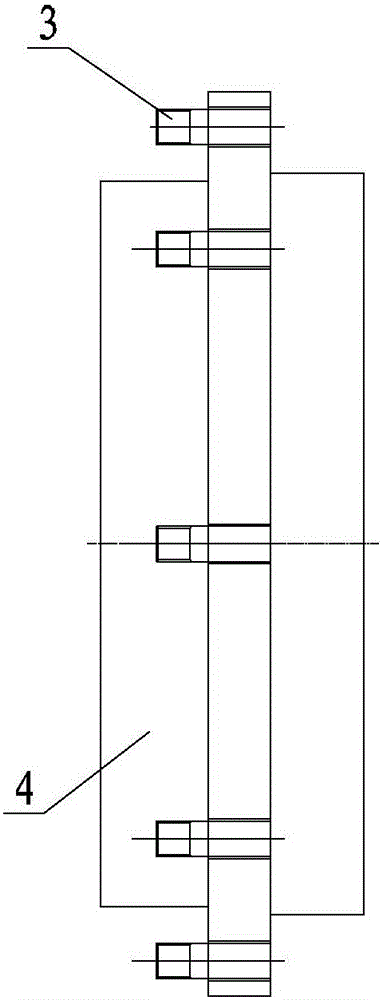

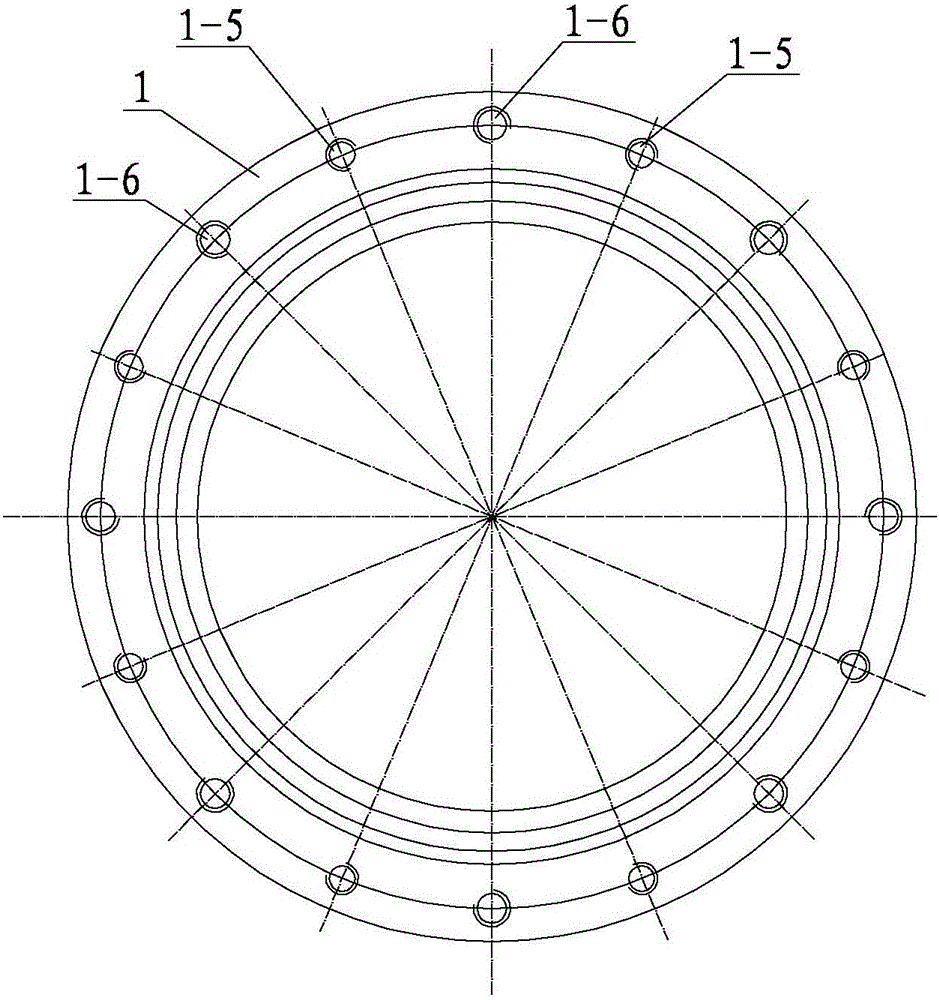

[0016] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this embodiment. This embodiment includes an adapter plate body 1, several M10 bolts 2 and several M12 bolts 3. The center of the adapter plate body 1 is provided with a stepped hole, and the stepped holes are tapered from left to right. Cabin connection hole 1-1, central hole 1-2 and tapered clamp connection hole 1-3, the inner diameter of the conical tail cabin connection hole 1-1 is smaller than the outer diameter, and the inner diameter of the tapered clamp connection hole 1-3 is smaller than Outer diameter, the outer surface of the adapter plate body 1 is provided with a flange 1-4, and the flange 1-4 is provided with several M10 threaded holes 1-5 and several M12 threaded holes 1-6 along the same circumference, each M10 One M10 bolt 2 is installed in the threaded holes 1-5, and one M12 bolt 3 is installed in each M12 threaded hole 1-6. One end of the M10 bolt 2 is a polished rod and the other...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination figure 1 and image 3 To describe this embodiment, several M10 threaded holes 1-5 and several M12 threaded holes 1-6 are alternately arranged in this embodiment. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination Figure 4 The present embodiment will be described. The thickness B of the adapter plate body 1 of the present embodiment is 25 mm to 35 mm. The thickness of the adapter plate body 1 is within the above numerical range to optimize the clamp rigidity. Other components and connections are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com