Fiber distribution frame

An optical fiber distribution frame and pigtail technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of inconvenient maintenance and maintenance, messy pigtails, unsightly, etc., to achieve the effect of easy maintenance and maintenance, and avoid the easy confusion of pigtails.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in combination with specific embodiments.

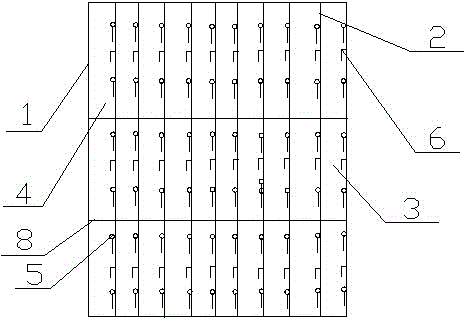

[0011] see figure 1 , an optical fiber distribution frame, including a box body 1, the box body 1 is divided into a plurality of vertical channels 3 by a plurality of vertical partitions 2, and each vertical channel 3 is divided into a plurality of vertical channels 3 by a horizontal partition 8 A pigtail coil 4 that can place pigtails, the pigtail coil 4 is provided with hanging ears 5 and fixed clips 6 for fixing pigtails; the horizontal partition 8 and the vertical partition 2 are provided with through holes 7 .

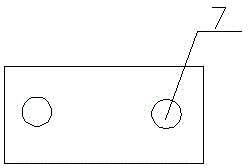

[0012] The vertical partition 2 and the horizontal partition 8 are respectively plastic partitions, the diameter of the through hole 7 of the vertical partition 2 in the vertical channel 3 is greater than the diameter of the through hole 7 in the pigtail coil 4, and the vertical partition 2 And the number of through holes 7 on the horizontal partition 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com