Backlight module, a narrow-frame liquid crystal display device and forming process of plastic frame

A technology for liquid crystal display devices and backlight modules, which is applied in the direction of light guides, optics, optical components, etc., can solve the problems of large brightness loss of backlight modules 100, uneven brightness and darkness of display screens, gray scale gradients of difficult-to-glue frames, etc., to achieve Save mold opening time, realize narrow frame design, and achieve the effect of small brightness loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

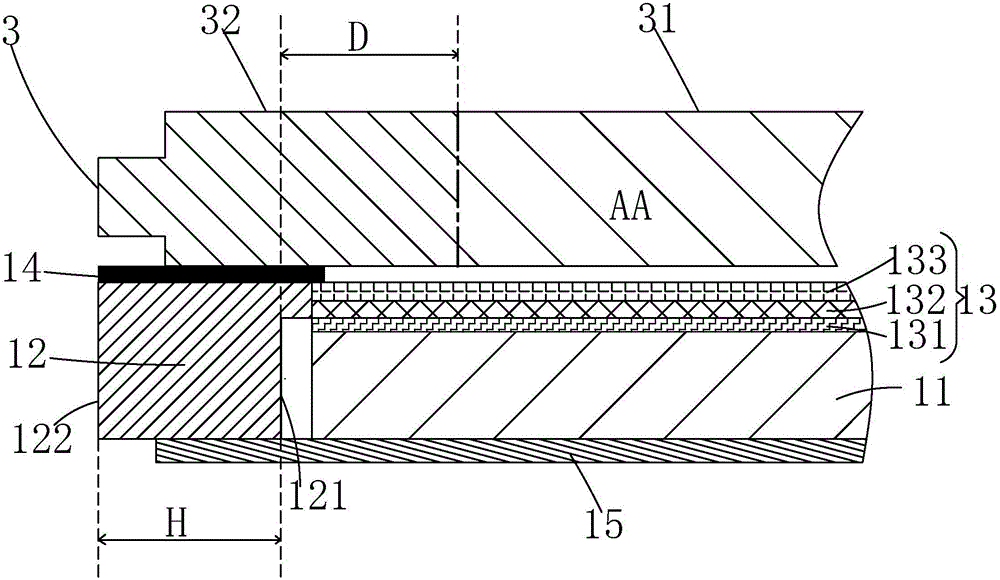

[0026] In order to further explain the technical means adopted by the present invention and its effects, the following describes in detail the preferred embodiments of the present invention and the accompanying drawings.

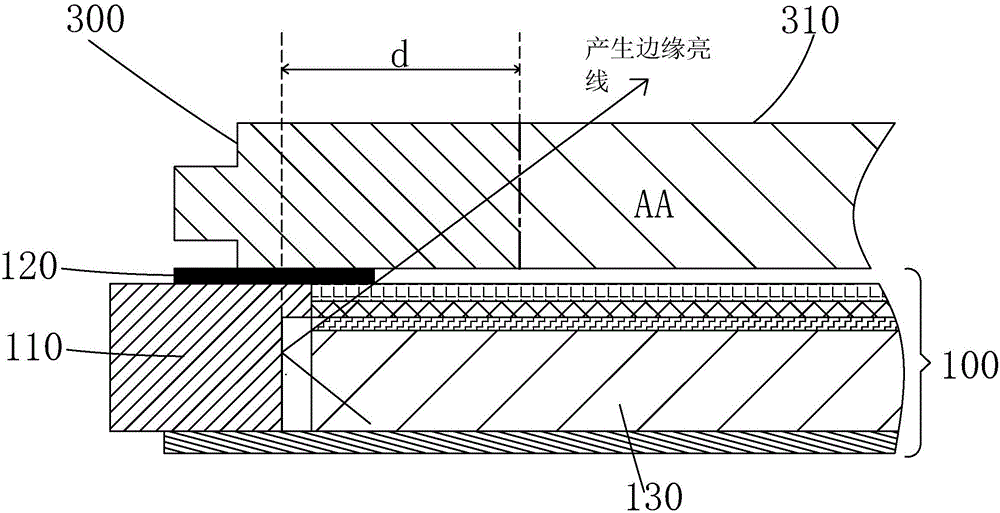

[0027] See figure 2 , The backlight module provided by the present invention includes: a light guide plate 11, a plastic frame 12 arranged on the outer periphery of the light guide plate 11, and a plastic frame 12 attached to the plastic frame 12 and covering the light guide plate 11 and the plastic frame 12 The gap between them extends to cover the word glue 14 on the periphery of the light guide plate;

[0028] The inner wall 121 of the plastic frame 12, which is in contact with the side surface of the light guide plate 11 and surrounds the light guide plate 11, has a gradual gray scale.

[0029] Specifically, each area on the inner wall of the plastic frame 121 receives the light from the light guide plate 11 at different intensities, and the inner wall 121 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com