A method for optimizing reaction conditions of industrial hydrocracking

A technology for hydrocracking and optimization methods, which is applied in data processing application, prediction, calculation, etc., can solve the problems that the processing method cannot achieve the optimization of multiple target parameters, and there are many operating parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

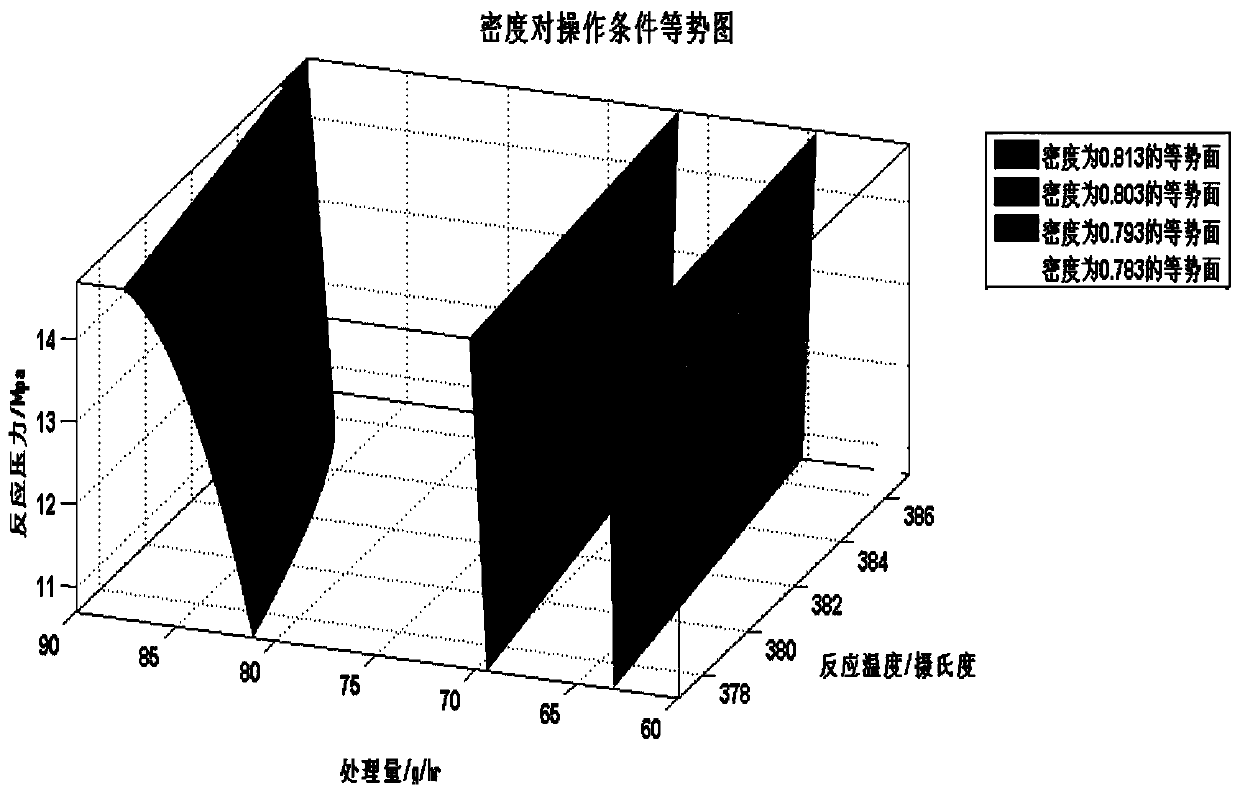

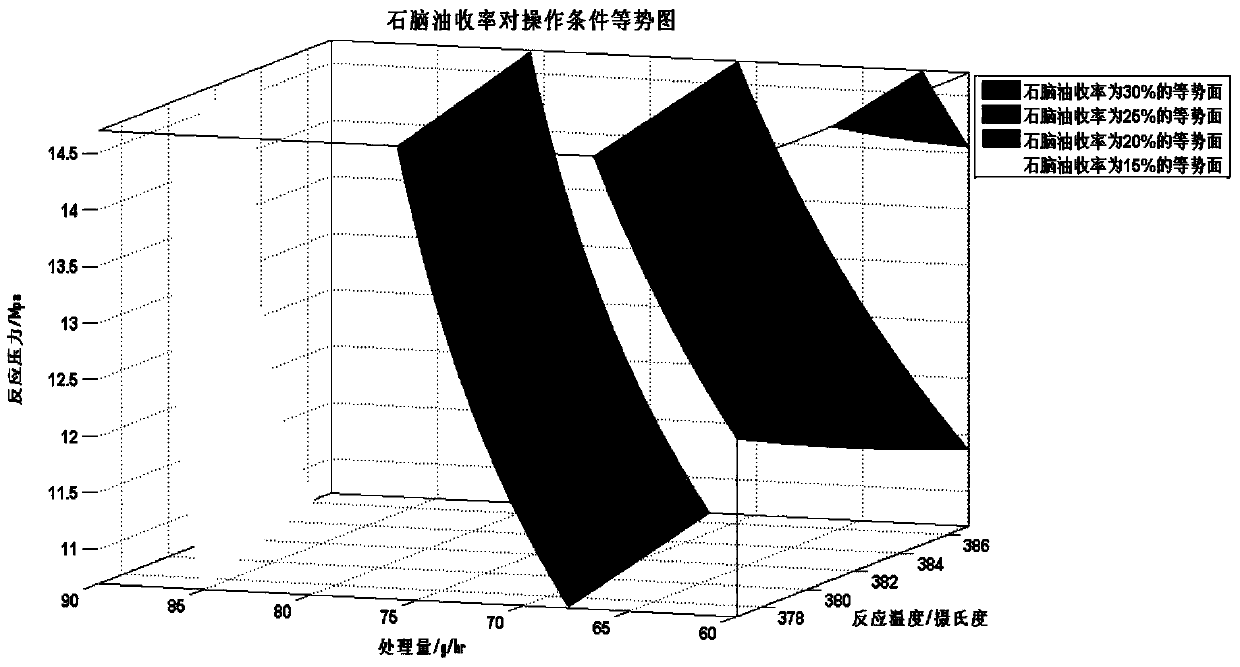

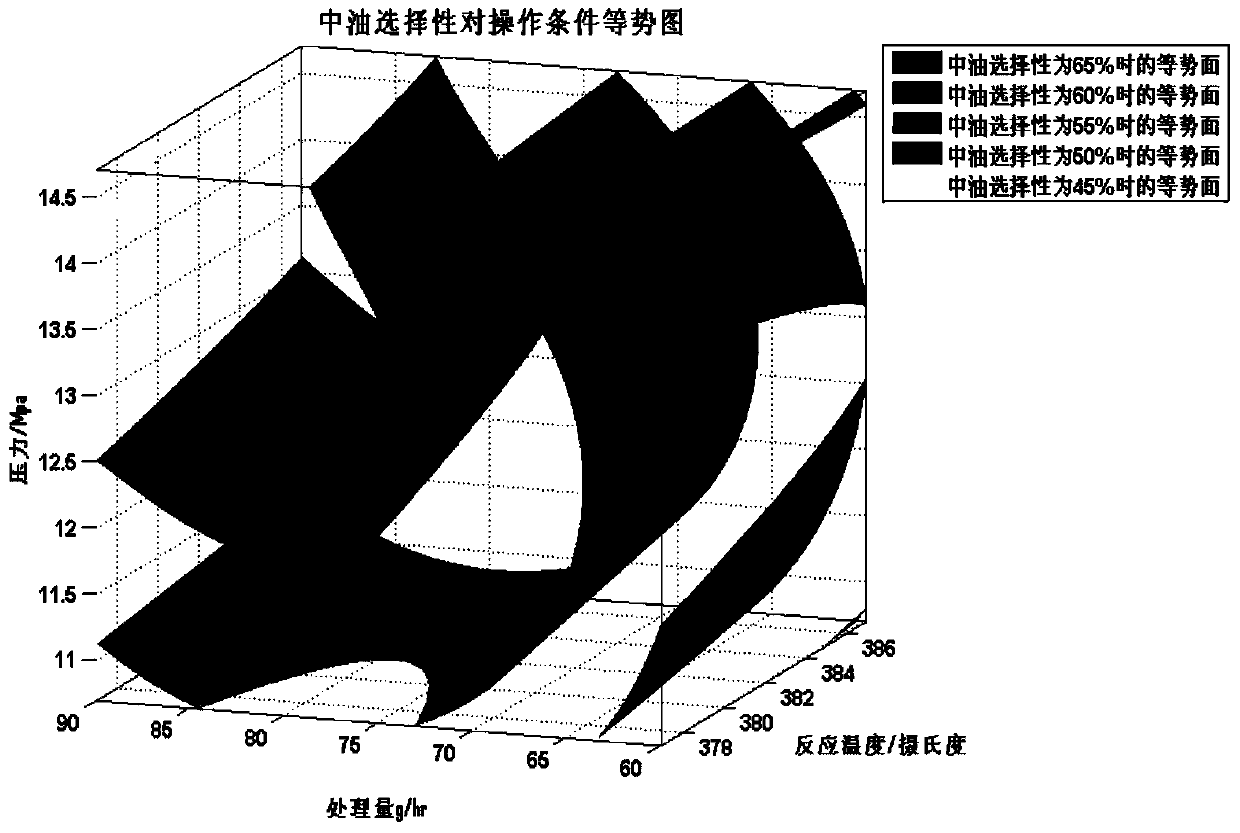

[0052] Firstly, the distillate oil products corresponding to 27 groups of experiments with different temperature, processing capacity and hydrogen partial pressure were sequentially extracted from the 40ml small-scale hydrogenation unit according to different process conditions, and the density of the produced oil and the yield of light naphtha under the 27 process operating conditions were respectively collected. rate and medium oil selectivity data. The temperature, processing capacity and hydrogen partial pressure of hydrocracking reaction were normalized respectively (divided by the maximum value of relevant process variables) as independent variables, and the density of produced oil, light naphtha yield and medium oil selectivity were used as independent variables. For the function, the third degree B-spline method is used for interpolation calculation, and three implicit numerical functions about the operating process variables and the properties of the three types of pro...

Embodiment 2

[0068] Example 2 is to optimize the conversion rate of the cracking reaction under the same algorithm conditions as in Example 1, only by adjusting the reaction temperature and the processing capacity. Since the calculation this time is the minimum value of the tail oil conversion rate of the optimization function, the adaptive function is written as the reciprocal of the objective function, and the rest of the method is the same as that of Embodiment 1. The objective function is the conversion rate of distillate oil (the conversion rate of raw material heavy oil into light component). The tail oil is the desired target product, and the tail oil no longer participates in the conversion.

[0069] The standard mathematical form of an optimization problem is:

[0070]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com