Liquid crystal display drive method and circuit

A technology of liquid crystal display and driving method, applied in static indicators, instruments, etc., can solve the problems of easy crosstalk, poor display effect, high power consumption, etc., to ensure picture quality, best picture quality, and reduce power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

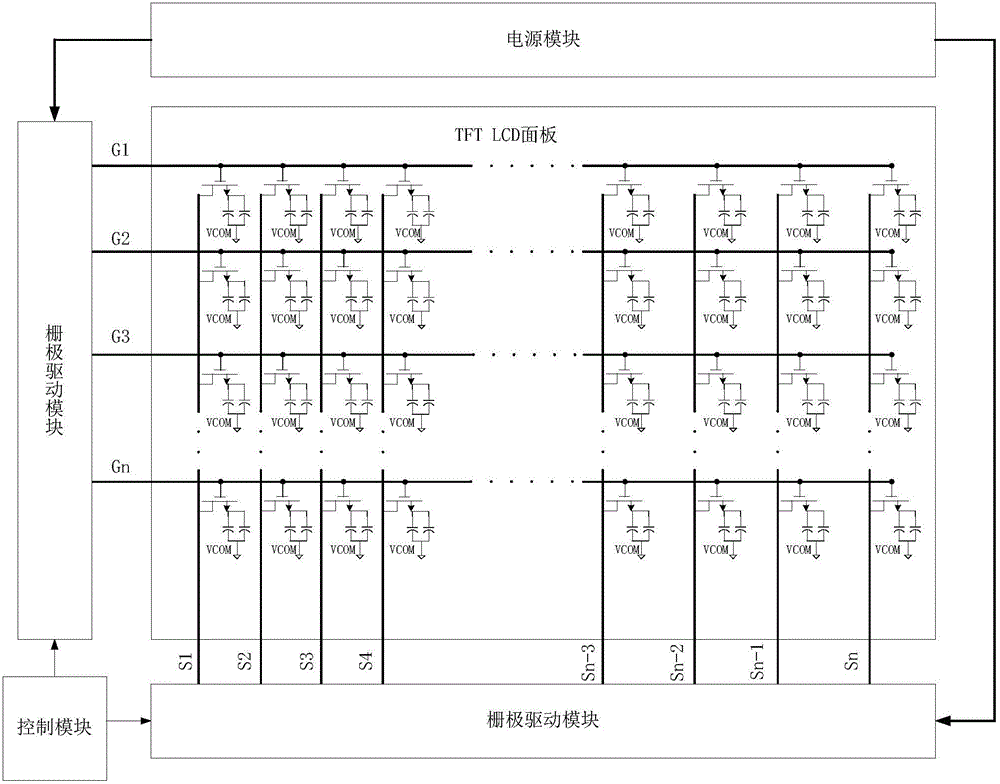

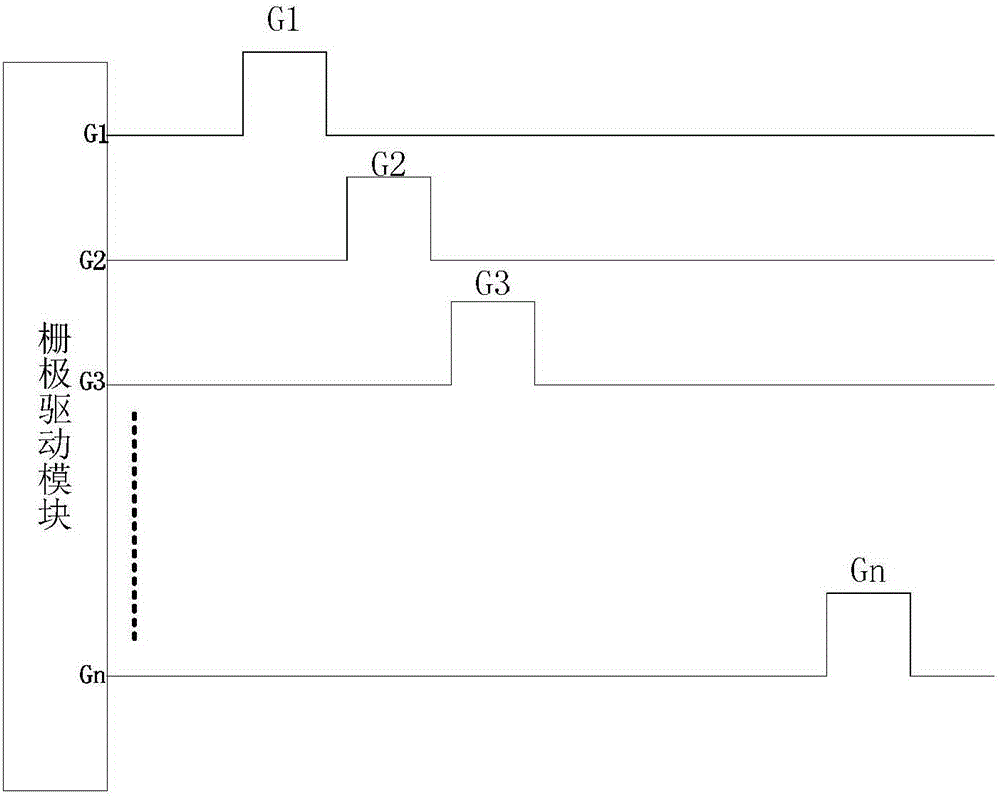

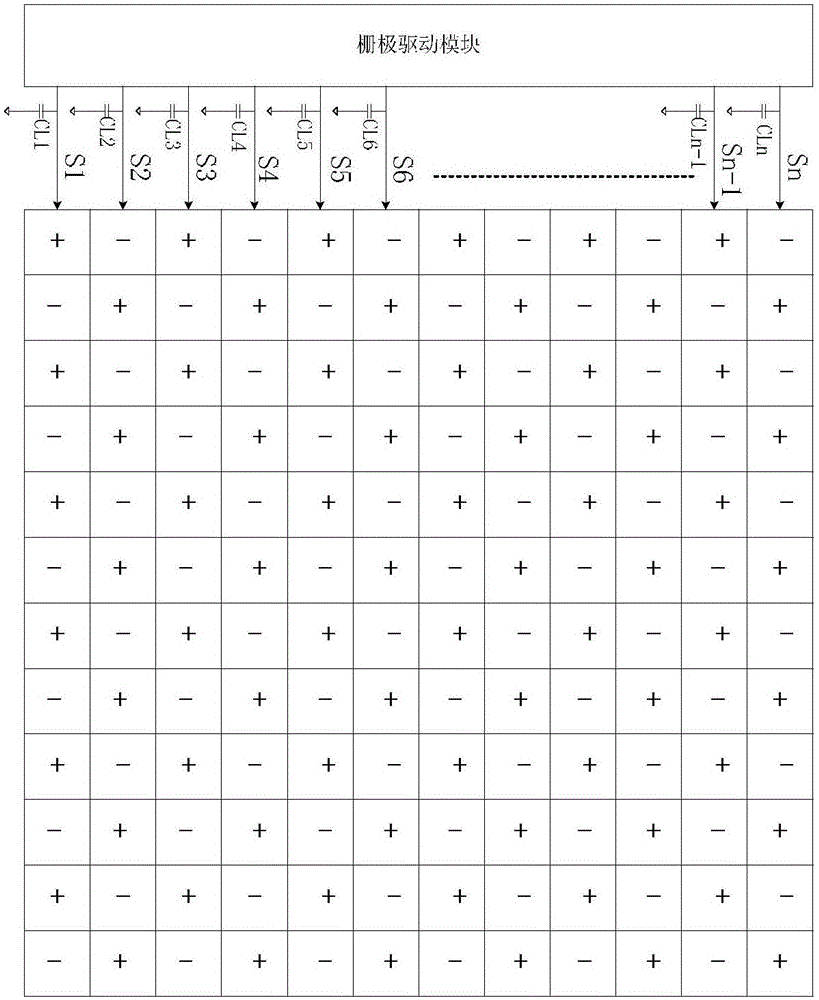

[0019] A method for driving a liquid crystal display with low power consumption, the method comprising: taking one frame as the minimum period, first sequentially turning on the gate drive scanning lines of each odd-numbered row, and each source drive scan line charges the corresponding pixel module ; After the pixel modules in odd rows are fully charged, turn on the gate drive scan lines of each even row in turn, and each source drive scan line charges the corresponding pixel modules.

[0020] As a further preferred embodiment, when the row is switched between rows, the polarity of the source driver module will not be reversed, and the charge on the parasitic capacitance of the wiring will not be switched between positive and negative, which can effectively reduce the power consumption. consumption.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com