Improved inner-pushing type clamping device for numerical control tube bending machine

A clamping device and an improved technology are applied in the field of an improved internal push-type clamping device for a numerically controlled pipe bender, which can solve the problems of poor rotary sealing of an oil cylinder, easy oil leakage, short service life, etc., so as to increase the convenience The effect of reducing the difficulty of sealing and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

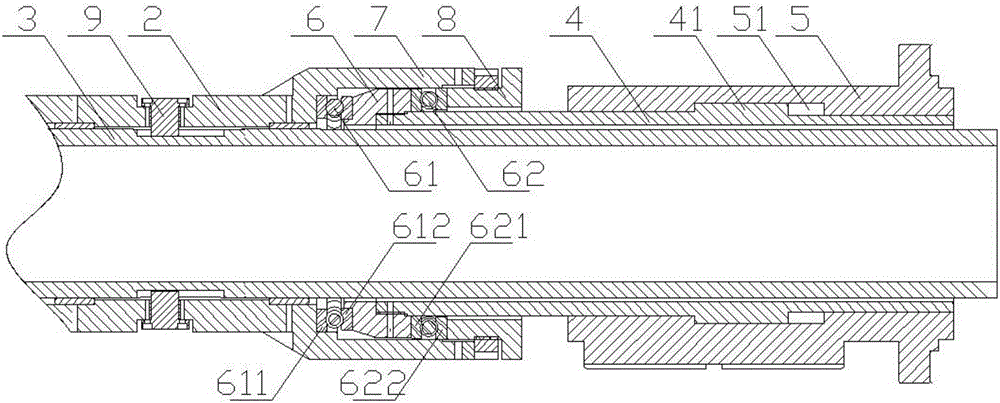

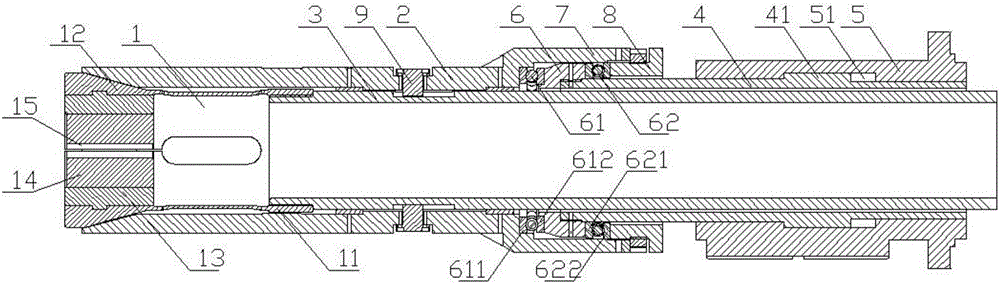

[0038] Such as image 3 As shown, an improved internal push-type clamping device for a CNC pipe bender includes a collet 1, an oil cylinder, and parts connecting the collet 1 and the cylinder, and the parts connecting the collet 1 and the cylinder include a push collet 2 and the rotating rod 3;

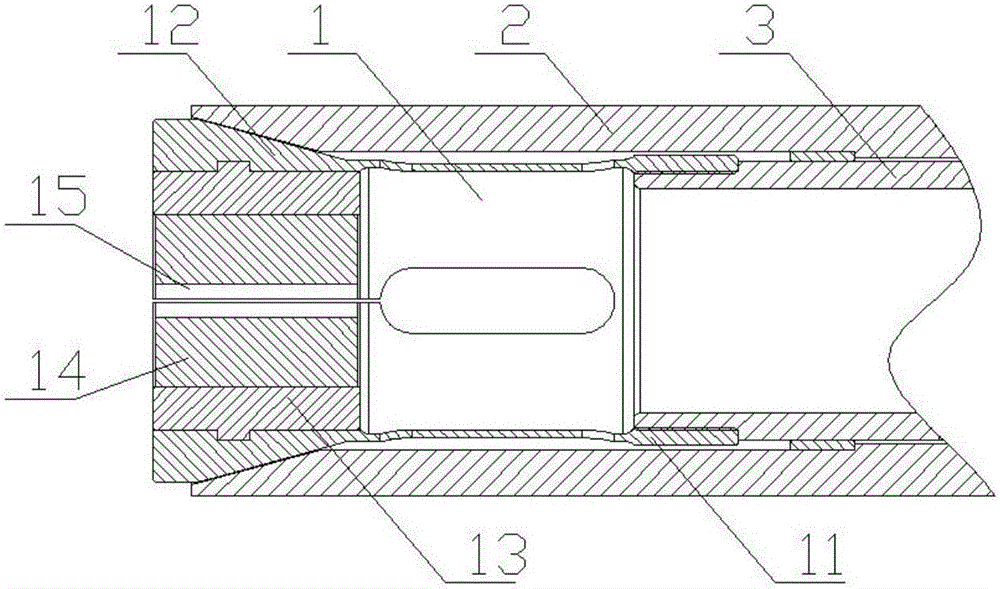

[0039] Such as figure 2 As shown, the oil cylinder includes a cylinder body 5 and a piston rod 4 arranged in the cylinder body 5. The push jacket 2 is arranged on the extended end of the piston rod 4. The push jacket 2 and the piston rod 4 are relatively fixed in the axial direction, and can be relatively fixed around the axis. Rotate, specifically, the extended end of the piston rod 4 is provided with a piston rod push clamp connecting seat 6; the connection between the push jacket 2 and the extended end of the piston rod 4 is provided with a rotating connecting sleeve 7 and a supporting sleeve 8; the rotating connecting sleeve 7 is set On the piston rod push clamp connection seat 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com