Amorphous thin strip tundish molten iron metering and control system

A control system and tundish technology, which are applied in the field of molten iron metering and control system for amorphous thin strip tundish, can solve the problems of uneven thickness of thin strips, affecting the flow rate of molten iron ejected from nozzles, etc., to ensure quality and liquid level. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

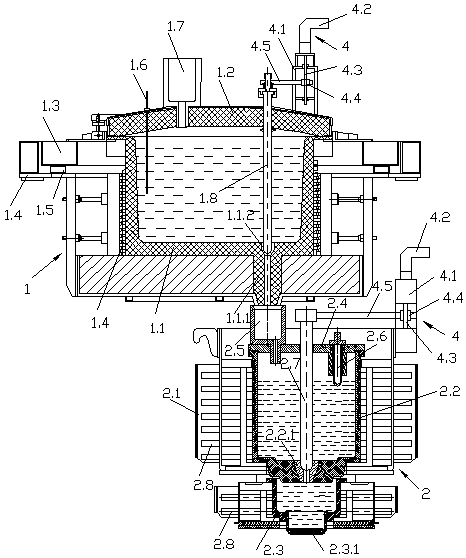

[0010] Embodiment 1: Amorphous thin strip tundish molten iron metering and control system, including tundish system 1, spray belt bag system 2 and computer control system, tundish system 1 includes tundish body 1.1, and is arranged on the top of tundish body 1.1 Tundish cover 1.2, tundish frame 1.3 fixing tundish body 1.1, induction coil 1.4 arranged on tundish body 1.1, said tundish frame 1.3 erected on walking support 1.4, tundish frame 1.3 and walking support 1.4 A weighing sensor 1.5 is provided at the erection place, and the tundish cover 1.2 is provided with a temperature sensor 1.6 extending into the tundish body 1.1, a molten iron diversion groove 1.7 communicating with the inner cavity of the tundish body 1.1, and a first stopper rod 1.8, the first stopper rod 1.8 is connected to the stopper rod driving device 4, the bottom end of the tundish 1.1 is provided with a bottom injection port 1.1.1, the bottom end of the bottom injection port 1.1.1 is provided with a nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com