Multi-abrasive particle abrasive belt

A technology of abrasive belts and abrasive grains, which is applied in abrasives, metal processing equipment, manufacturing tools, etc., and can solve problems such as wasting time, manpower, high speed of grinding wheels, and poor safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

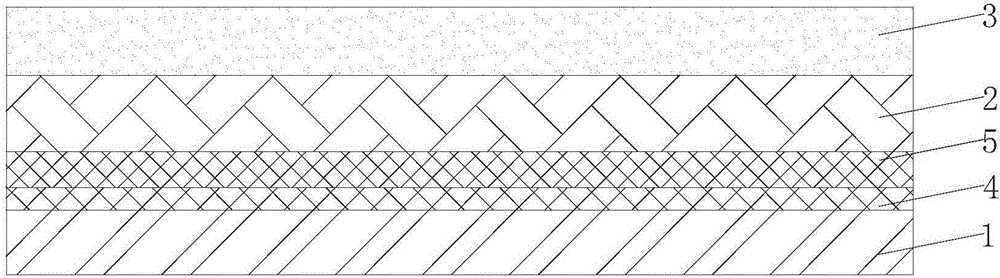

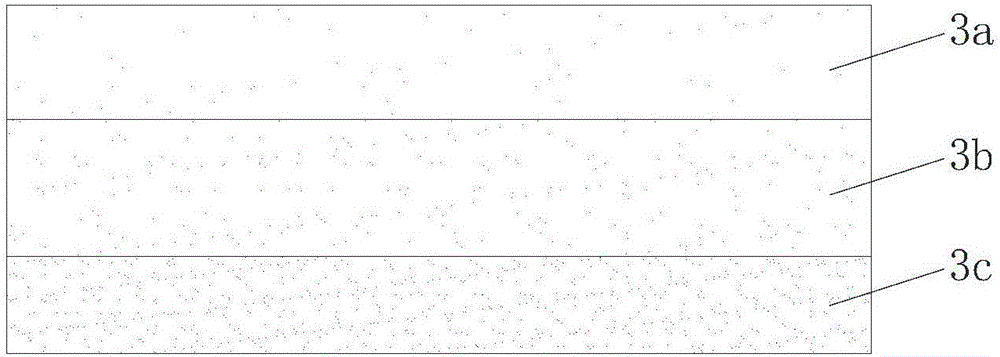

[0015] see figure 1 and figure 2 , the abrasive belt of the present invention includes a base 1, a bonding layer 2 and an abrasive layer 3, the base 1 is a continuous plane, and also includes a reticulated reinforcing layer 4, after the reticulated reinforcing layer 4 is fixed on the base 1, the reticulated The network-shaped reinforcing layer 1 is located between the substrate 1 and the adhesive layer 2, and the network-shaped reinforcing layer 4 is fixed on the substrate 1 by bonding. Since the mesh reinforcement layer 4 is mesh-shaped, the mesh reinforcement layer 4 has a force on the substrate 1 during operation, and the continuous plane of the substrate 1 contributes to the increased overall strength to prevent the mesh reinforcement The active force of the layer 4 tears the substrate 1, therefore, the present invention prevents the sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com