A device for retrieving rubber parts of injection molding machines

A technology for rubber parts and injection molding machines, which is applied in the field of auxiliary devices of injection molding equipment, can solve the problems of uneven direction of force on rubber parts, easy to fall in the mold, mold cleaning, and lower product qualification rate, etc. Reduce labor costs and labor intensity of workers, the effect of good performance matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

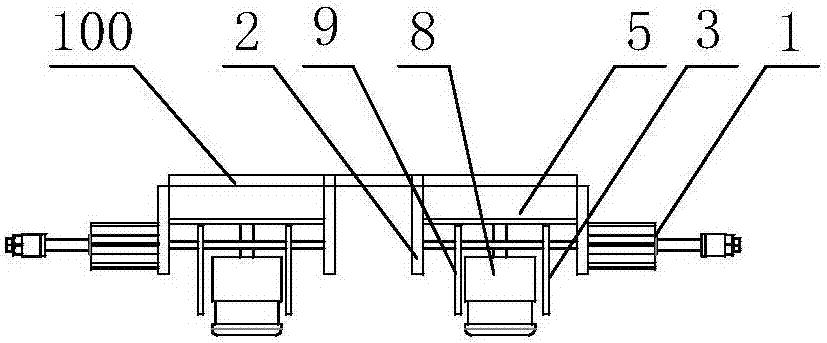

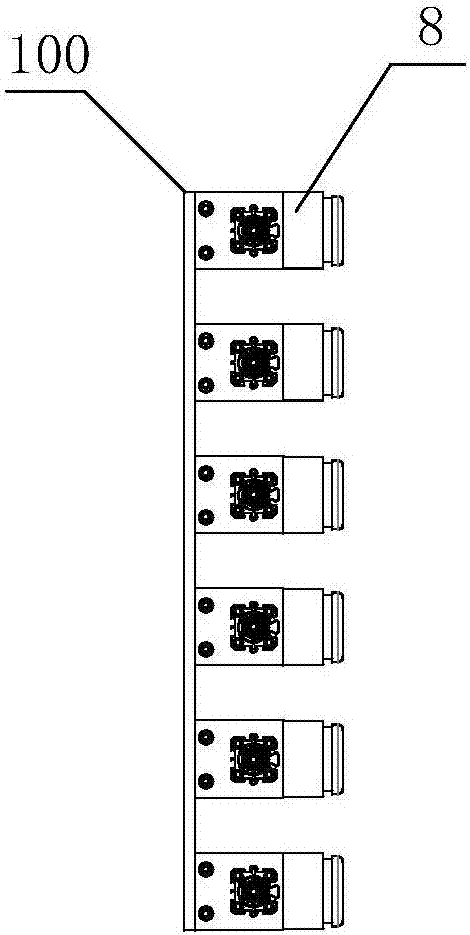

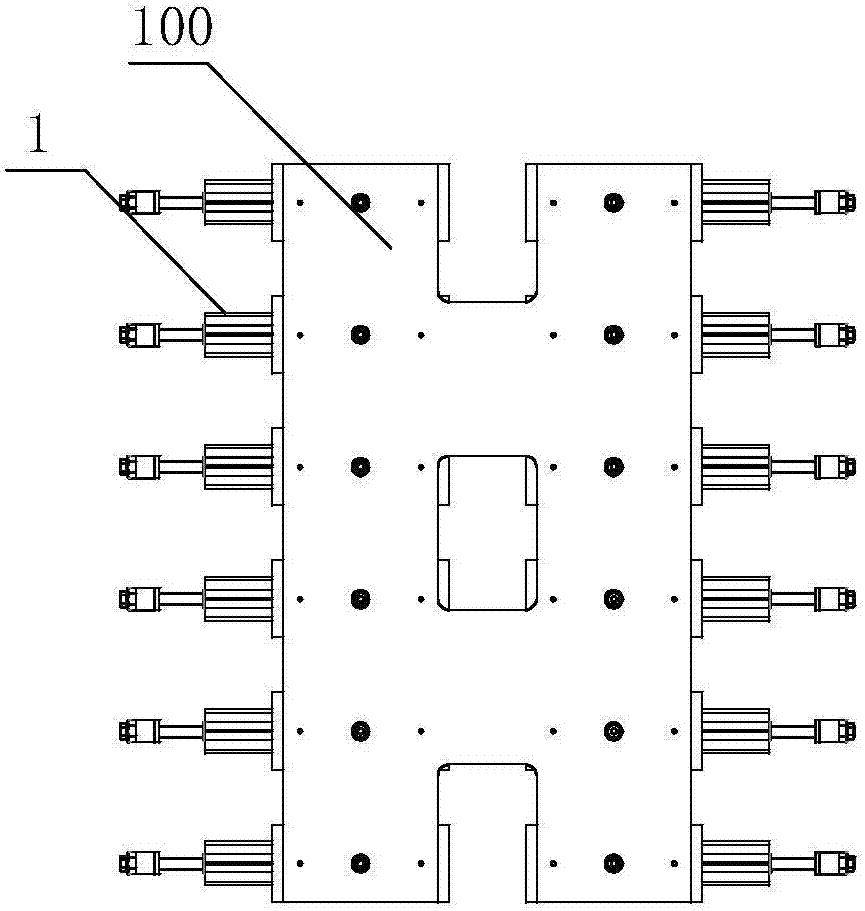

Embodiment 1

[0032] A device for reclaiming rubber parts of an injection molding machine, comprising 12 groups of grabbing units with the same structure arranged one after the other and installed on the bottom surface of the connecting plate 100. The grabbing unit includes a blow tube 8 and installed on both sides of the blow tube The main gripper 3 and the secondary gripper 9 are installed in the center of the cover plate 7 through the air inlet pipe 6 connected to the blower. The upper part of the cover plate is connected to the slide plate 5, and slide grooves 51 are provided on both sides of the slide plate to slide the main The rack 11 and the auxiliary rack 12 are provided with a circular groove in the center of the slide plate, and the gear 10 installed in the circular groove and taking the air intake pipe as the axis is respectively connected with the main rack and the auxiliary rack installed in the sliding groove The main gripper and the secondary gripper are respectively installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com