Preparation method of lignin and boron dual-modified phenolic resin and phenolic moulding plastic

A phenolic molding compound, double modification technology, applied in the field of preparation of phenolic resin and phenolic molding compound, can solve the problems of low reactivity, low content, poor toughness of molding compound, etc., achieve excellent mechanical properties, reduce production costs, and good thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

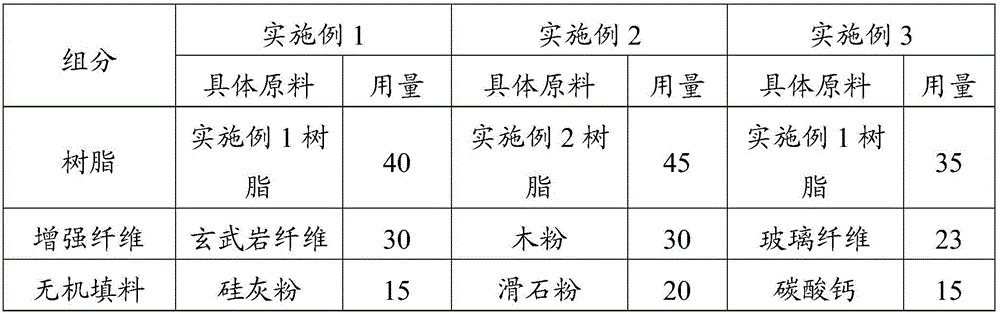

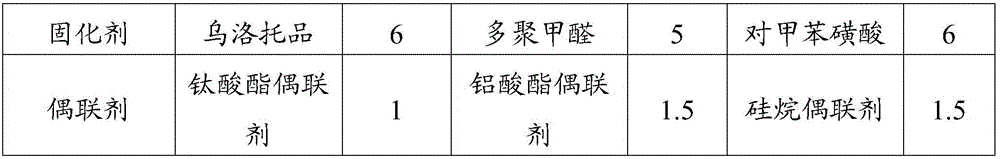

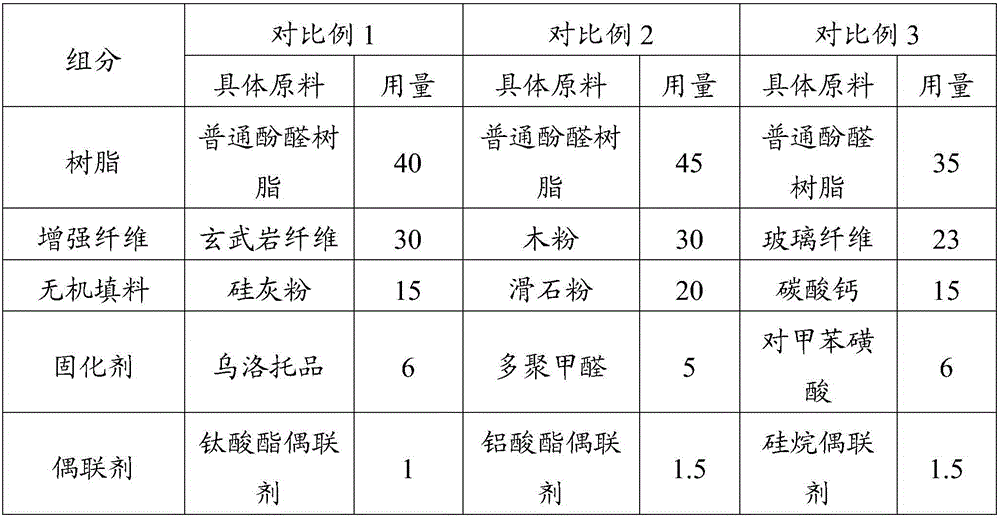

Examples

preparation example Construction

[0017] Specifically, the preparation method of lignin and boron double modified phenolic resin provided by the invention comprises:

[0018] Add lignin, acidic catalyst and phenol into the reaction kettle, heat up to boiling, and reflux for 1-5h;

[0019] Add organic boron compound and aldehyde to the reaction solution, react at 90-110°C for 1-5h, and dehydrate to obtain lignin-boron double-modified phenolic resin.

[0020] Wherein, the lignin is preferably lignosulfonate, alkali lignin, enzymatic lignin, acid lignin or high boiling alcohol lignin. Lignin is a substance with a certain molecular weight. Too much addition will make the prepared phenolic resin too viscous and poor in processing performance. Reasonable selection of lignin addition can not only give full play to the modification effect of lignin on phenolic resin, but also The phenolic resin with good fluidity can be obtained, and the amount of lignin is preferably 1%-50% of the phenol mass, more preferably 10-30%...

Embodiment 1

[0035] 1) Add 25 parts by weight of enzymatic lignin, 1 part by weight of oxalic acid and 100 parts by weight of phenol into the reaction kettle, heat up to boiling, and then reflux for 5 hours;

[0036] 2) Add 10 parts by weight of 2-aminoethyl diphenylboronate and 80 parts by weight of formaldehyde to the reaction solution in step 1), react at 100°C for 5 hours, and dehydrate to obtain double-modified lignin and boron Phenolic Resin.

Embodiment 2

[0038] 1) Add 15 parts by weight of calcium lignosulfonate, 0.9 parts by weight of oxalic acid and 100 parts by weight of phenol into the reaction kettle, heat up to boiling, and then reflux for 3 hours;

[0039] 2) Add 30 parts by weight of L-norvalyl diphenyl borate and 95 parts by weight of formaldehyde solution with a mass concentration of 37% to the reaction solution in step 1), react at 100°C for 2 hours, and then dehydrate A phenolic resin double-modified by lignin and boron is obtained.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap