A hydraulic slide valve

A technology of hydraulic slide valve and valve core, applied in the field of hydraulic valve, can solve problems such as cost increase and waste of resources, and achieve the effect of saving resources and costs, ensuring matching and ensuring unity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

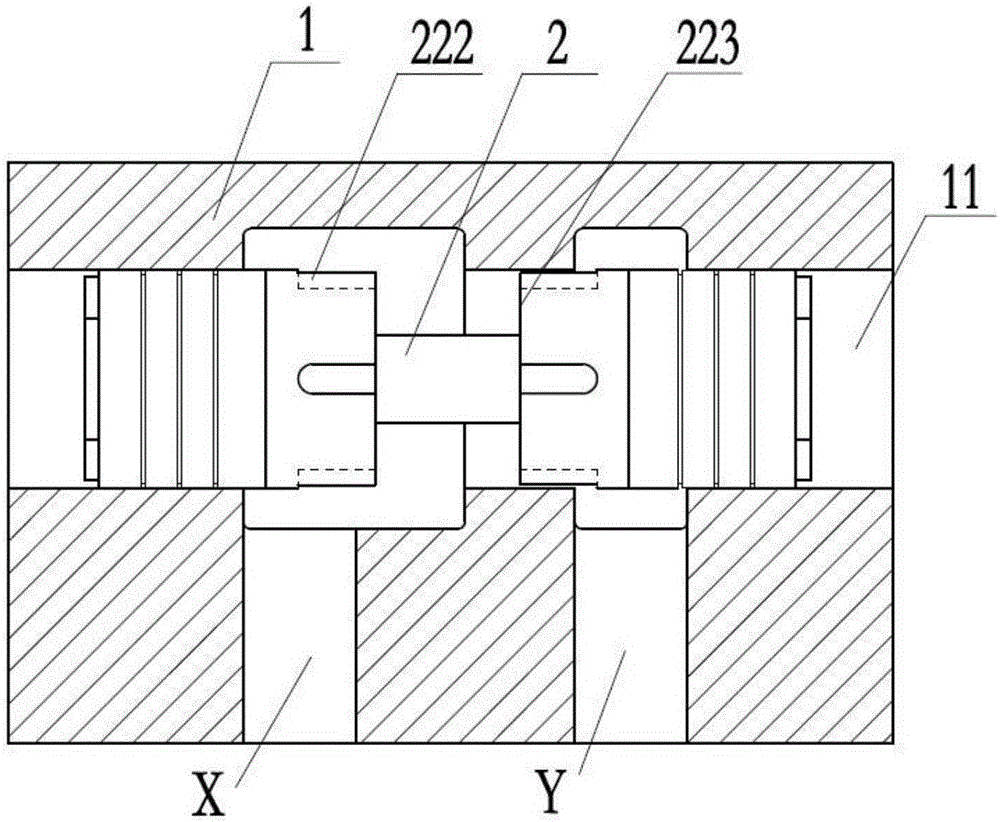

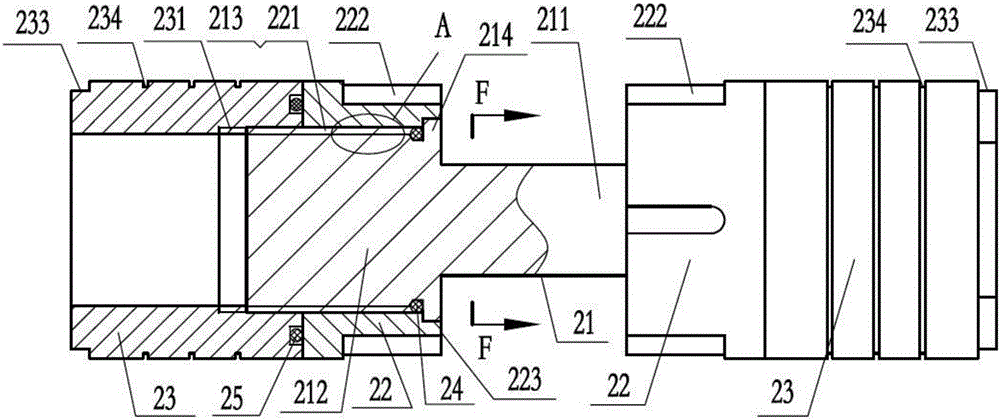

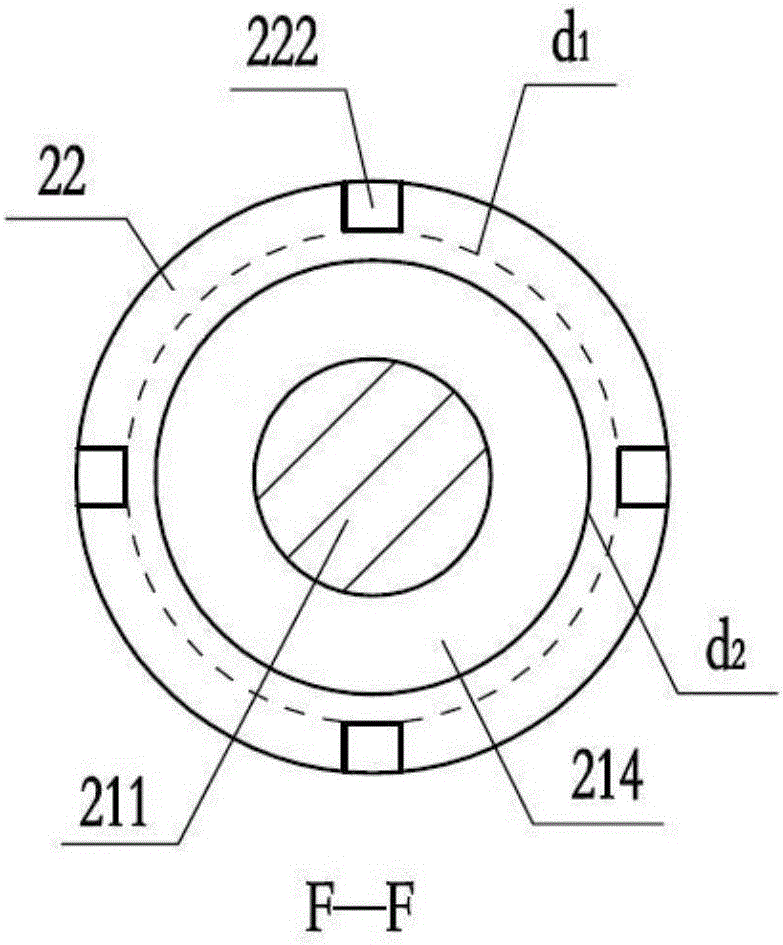

[0025] figure 1 It is a partial structural schematic diagram of the hydraulic slide valve of the present invention. The hydraulic slide valve includes a valve body 1 and a valve core 2, and the valve body 1 is provided with a valve body hole 11 and an oil passage X and an oil passage Y for oil circulation. The spool 2 is located in the valve body hole 11 and moves left and right along the axis of the valve body hole 11 to control the communication state of the oil passage X and the oil passage Y, and under the action of the throttling groove 222 and the control edge 223 of the valve port, realize Oil control. By adjusting the structural size of the throttle groove 222, the hydraulic slide valve can have different control characteristics.

[0026] During the working process of the hydraulic slide valve, when the high-pressure oil and the solid particles in the oil pass through the oil passage X and the oil passage Y, they will cause erosion and wear to the throttling groove 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com