Shaft seal installation tool and installation method

A technology for installing tools and installation methods, which is applied in the directions of manufacturing tools, engine sealing, hand-held tools, etc., can solve the problems of long time-consuming, leaking, and affecting the sealing effect of the sealing ring to restore the size by itself.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

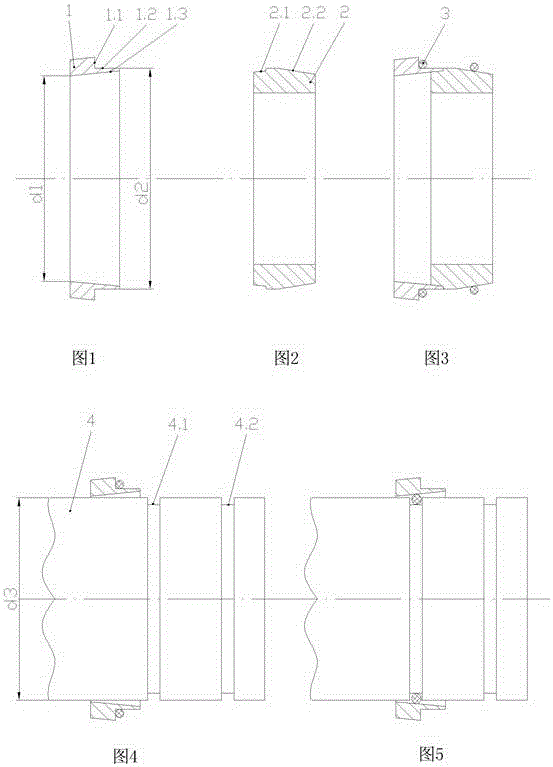

[0017] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

[0018] figure 1 The mounting ring 1 shown includes a radial support surface 1.1, an axial support surface 1.2, and an inner conical surface 1.3. The outer diameter d2 of the axial support surface 1.2 is larger than the minimum inner diameter d1 of the inner conical surface 1.3 and its width is larger than that of the sealing Sectional diameter of the ring 3; the minimum inner diameter d1 of the inner conical surface 1.3 is adapted to the predetermined sealing size of the sealing ring 3 and is slightly larger than the outer diameter d3 of the shaft 4 on which the sealing ring 3 needs to be installed. The end of the axial support surface 1.2 is rounded, so that the surface of the sealing ring 3 will not be damaged when the sealing ring 3 is inserted.

[0019] As a preferred solution, especially for some sealing rings with poor elasticity, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com