Floating type static spring seat and mechanical sealing structure thereof

A spring seat, static technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems that affect the compensation of the end face of the mechanical seal by the spring, affect the function of spring compensation, and affect the use effect of the spring seat, etc. Simple, improved sealing performance, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

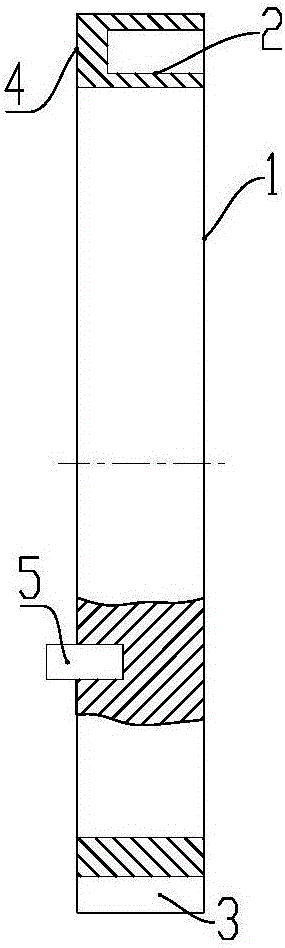

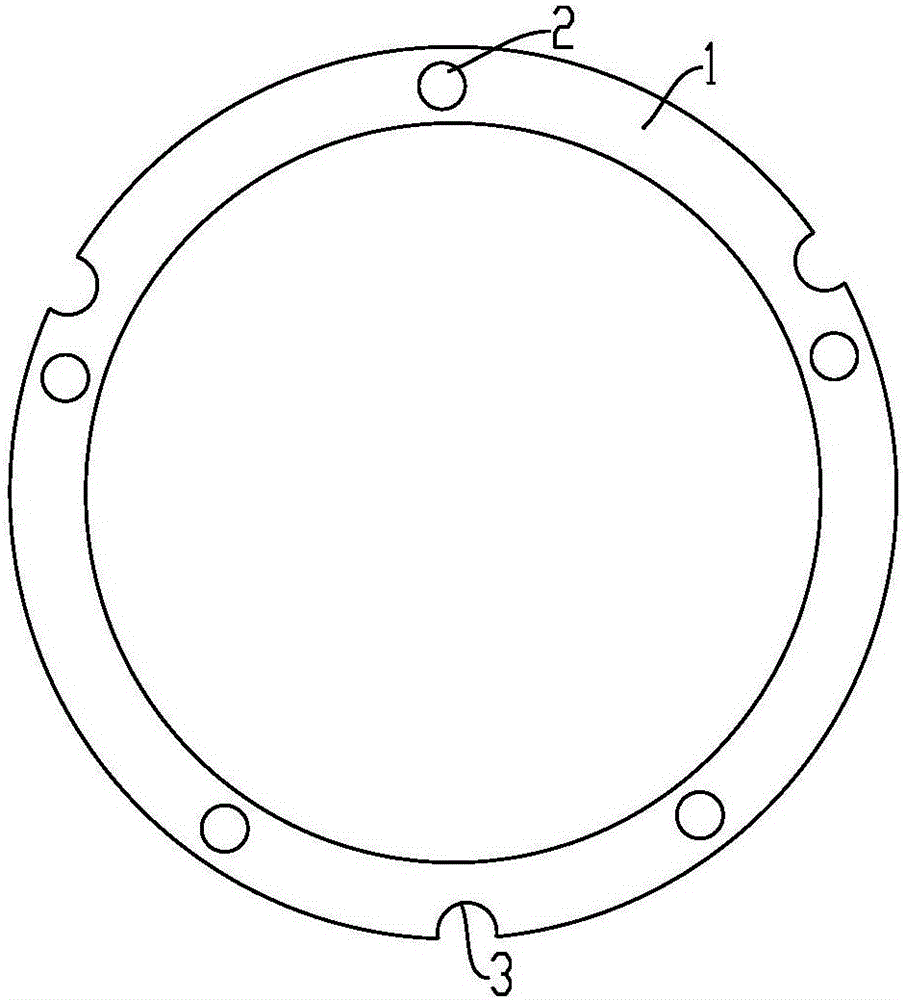

[0027] Such as figure 1 with 2 , a floating static spring seat, comprising an annular spring seat body 1, one end surface of the spring seat body 1 is an action surface 4 that interacts with a mechanical seal assembly, and the spring seat body 1 is connected to the action surface 4 A plurality of spring holes 2 are provided on the opposite end surface, and an anti-rotation structure that restricts the rotation of the spring seat is provided on the outside of the circumference of the spring seat body 1. The anti-rotation structure here is used to realize the sealing case of the spring seat and the mechanical seal. The connection between them is used to prevent the spring seat from rotating when the mechanical seal is working. The anti-rotation structure in this embodiment adopts at least one anti-rotation groove 3 outside the circumference of the spring seat body. Of course, other Similar structure, as long as there is no relative rotation between the spring seat and the seali...

Embodiment 2

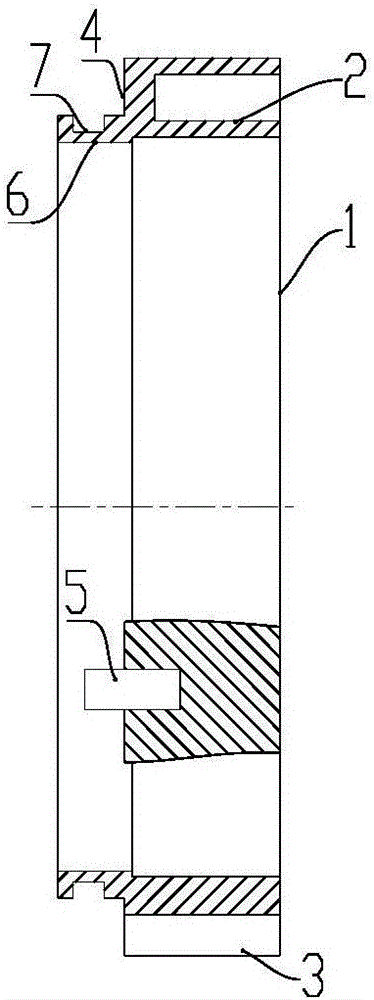

[0031] Such as image 3 As shown, a floating static spring seat includes an annular spring seat body 1, the end surface of one side of the spring seat body 1 is an active surface 4 that interacts with the mechanical seal assembly, and the spring seat body 1 is connected to the acting surface 4. A plurality of spring holes 2 are provided on the opposite end surface of the surface 4, and at least one anti-rotation groove 3 is provided on the outside of the circumference of the spring seat body 1; an outwardly extending support ring is provided on the active surface of the spring seat body 6. The support ring 6 is provided with an annular groove 7, and the support ring 6 and the spring seat body 1 are of an integral structure.

[0032] During installation, the supporting ring 6 of the spring seat extends into the static ring, and the outer peripheral surface of the supporting ring 6 cooperates with the inner peripheral surface of the static ring. There is good coaxiality between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com