Multi-way valve

A multi-way valve and valve body technology, applied in the field of multi-way valves, can solve the problems of difficult control of reaction device pressure and reaction speed, single application, high cost, etc., and achieve the effect of simple and practical structure, easy operation and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

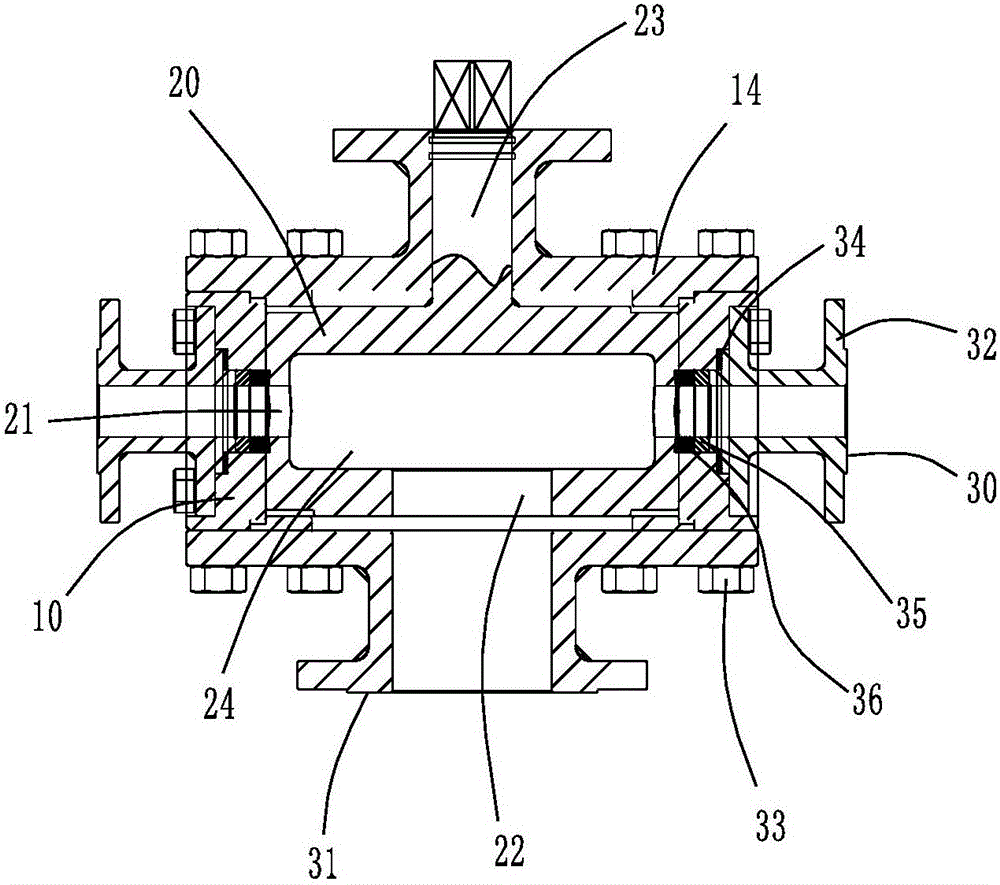

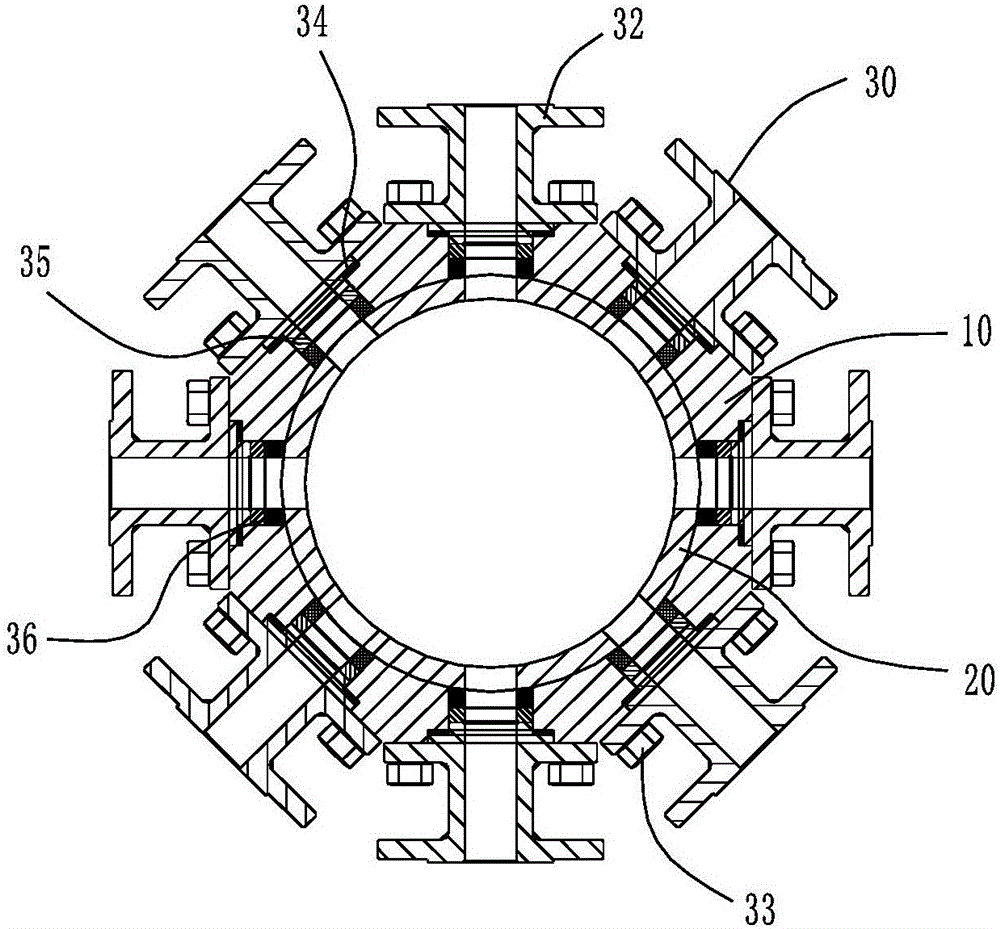

[0035] see figure 1 , figure 2 and image 3 As shown, the embodiment of the present invention provides a multi-way valve, including a valve body 10, a valve core 20, a side connecting pipe 30 and a lower connecting pipe 31,

[0036] Such as Figure 4 and Figure 6 As shown, the valve body 10 is cylindrical, and the valve body 10 is provided with a cylindrical valve body cavity 11. The valve body 10 is provided with 8 valve body passages 12 at equal intervals on the same circumference, and the valve body passages 12 It communicates with the valve body cavity 11. Valve body 10 is provided with mounting hole 13, and mounting hole 13 is arranged coaxially with valve body cavity 11, and the diameter of its mounting hole 13 is larger than the diameter of spool 20, and the top of mounting hole 13 is provided with bonnet, and on bonnet 14 A through hole 15 is provided, the through hole 15, the installation hole 13 and the valve body cavity 11 are coaxially arranged, and the end ...

Embodiment 2

[0042] see Figure 9 and Figure 10 As shown, the difference between embodiment 2 and implementation 1 is:

[0043] In Embodiment 1, the valve body 10 is provided with 8 valve body passages 12 at equal intervals in the circumferential direction on the same circumference, and 8 valve core passages 21 are arranged at equal intervals in the circumferential direction of the valve core 20 on the same circumference, and the valve core passages 21 and The valve body passages 12 are connected to form 8 inlet passages.

[0044] In Embodiment 2, the valve body passages 12 of the valve body 10 are arranged on two circumferences, the two circumferences are arranged up and down, 4 valve body passages 12 are arranged at equal intervals on the upper circumference, and 4 valve passages are arranged at equal intervals on the lower circumference. body channel 12, and project the valve body channel 12 of the upper layer and the valve body channel 12 of the lower layer along the axial direction o...

Embodiment 3

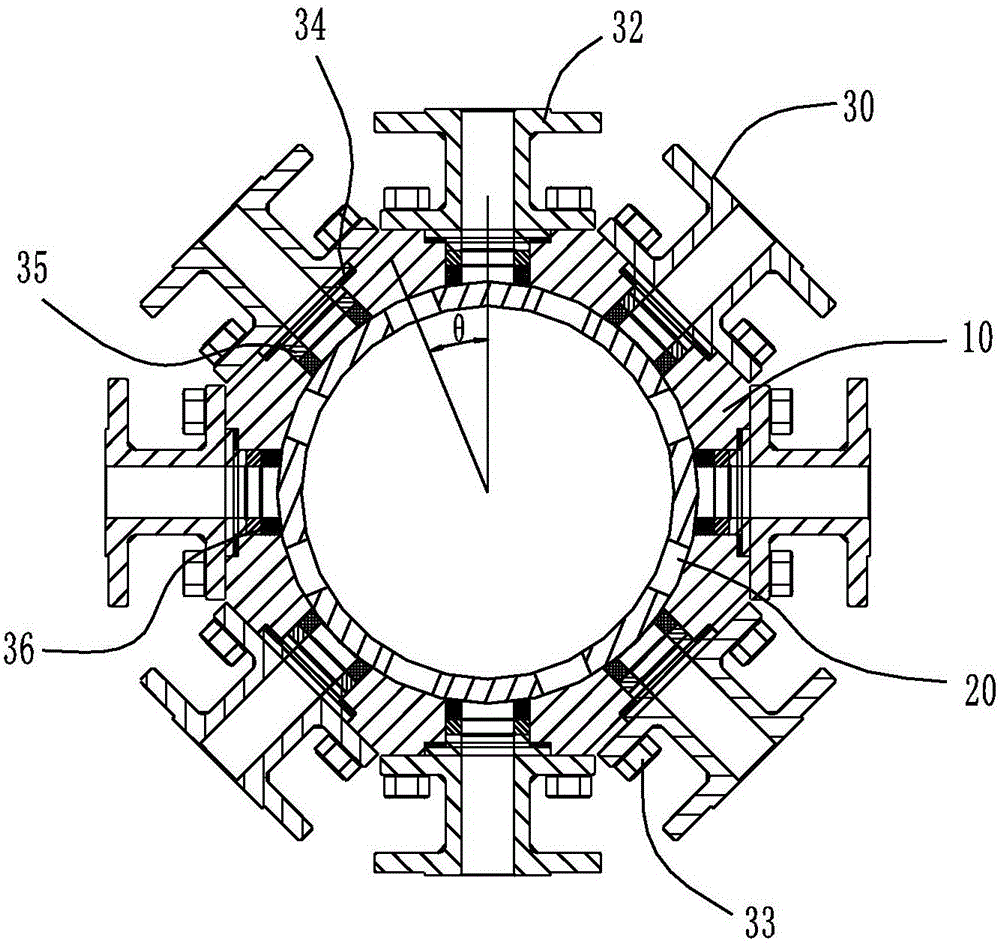

[0046] The difference between embodiment 3 and embodiment 1 is:

[0047] In Embodiment 1, the valve body 10 is provided with 8 valve body passages 12 at equal intervals in the circumferential direction on the same circumference, and 8 valve core passages 21 are arranged at equal intervals in the circumferential direction of the valve core 20 on the same circumference, and the valve core passages 21 and The valve body passages 12 are connected to form 8 inlet passages.

[0048] In Embodiment 3, the valve body 10 is provided with four valve body passages 12 at intervals on the same circumference, and the distances between adjacent valve body passages 12 are not equal. A spool passage 21 is provided, and the spool passage 21 communicates with the valve body passage 12 to form 4 inlet passages. Within a certain range, the inlet passages of the valve can be opened or closed at the same time, and can also be rotated to make a certain inlet passage communicate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com