Three-phase three-dimensional lamination iron core of three-phase reactor

A three-dimensional laminated, three-phase reactor technology, which is applied to transformer/inductance parts, circuits, electrical components, etc., can solve the problems of unequal reactance values of three-phase reactors, magnetic flux loss of three-phase reactors, and distance Incompatibility and other problems, to achieve the effect of reducing loss, reducing eddy current loss, and high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

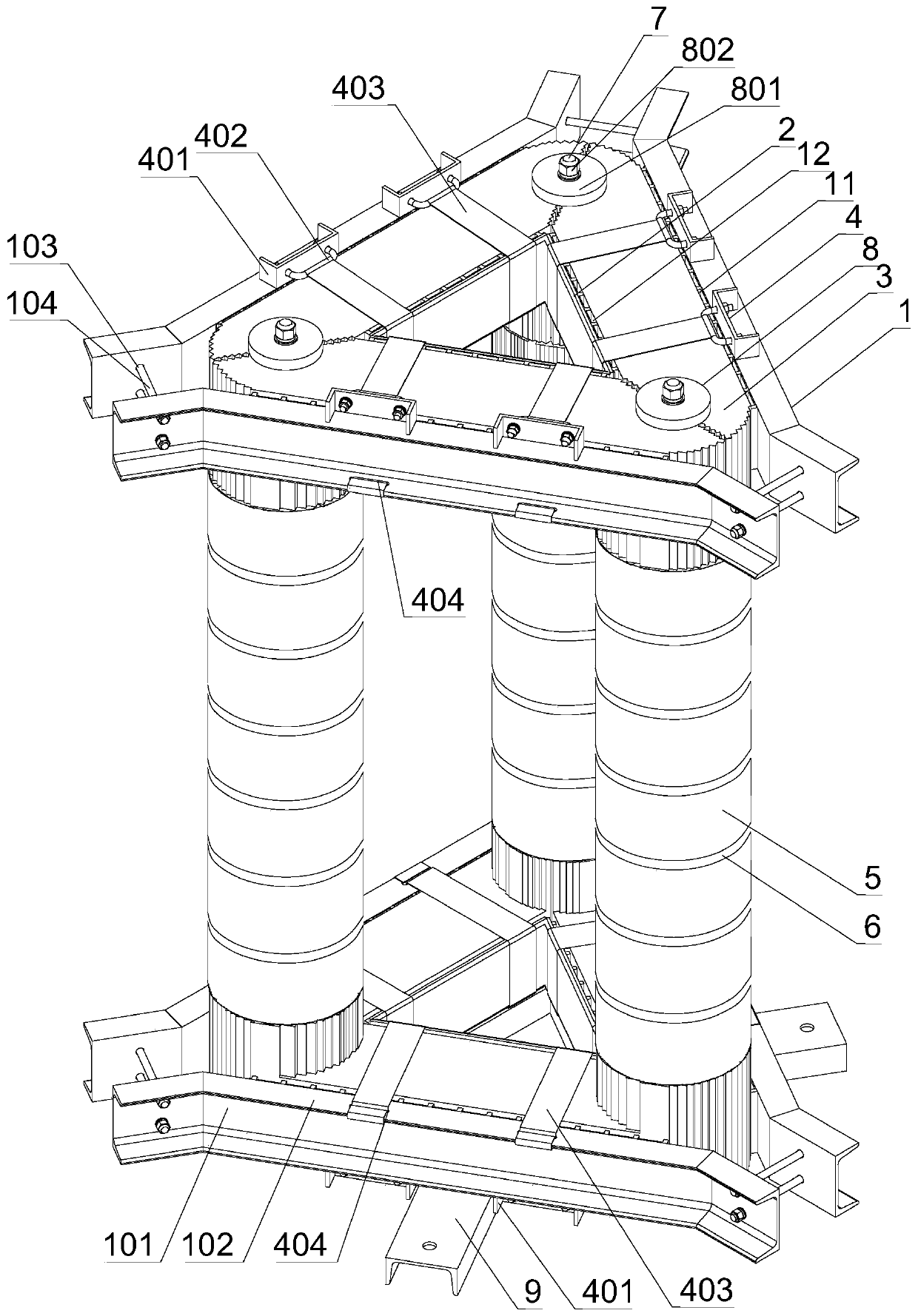

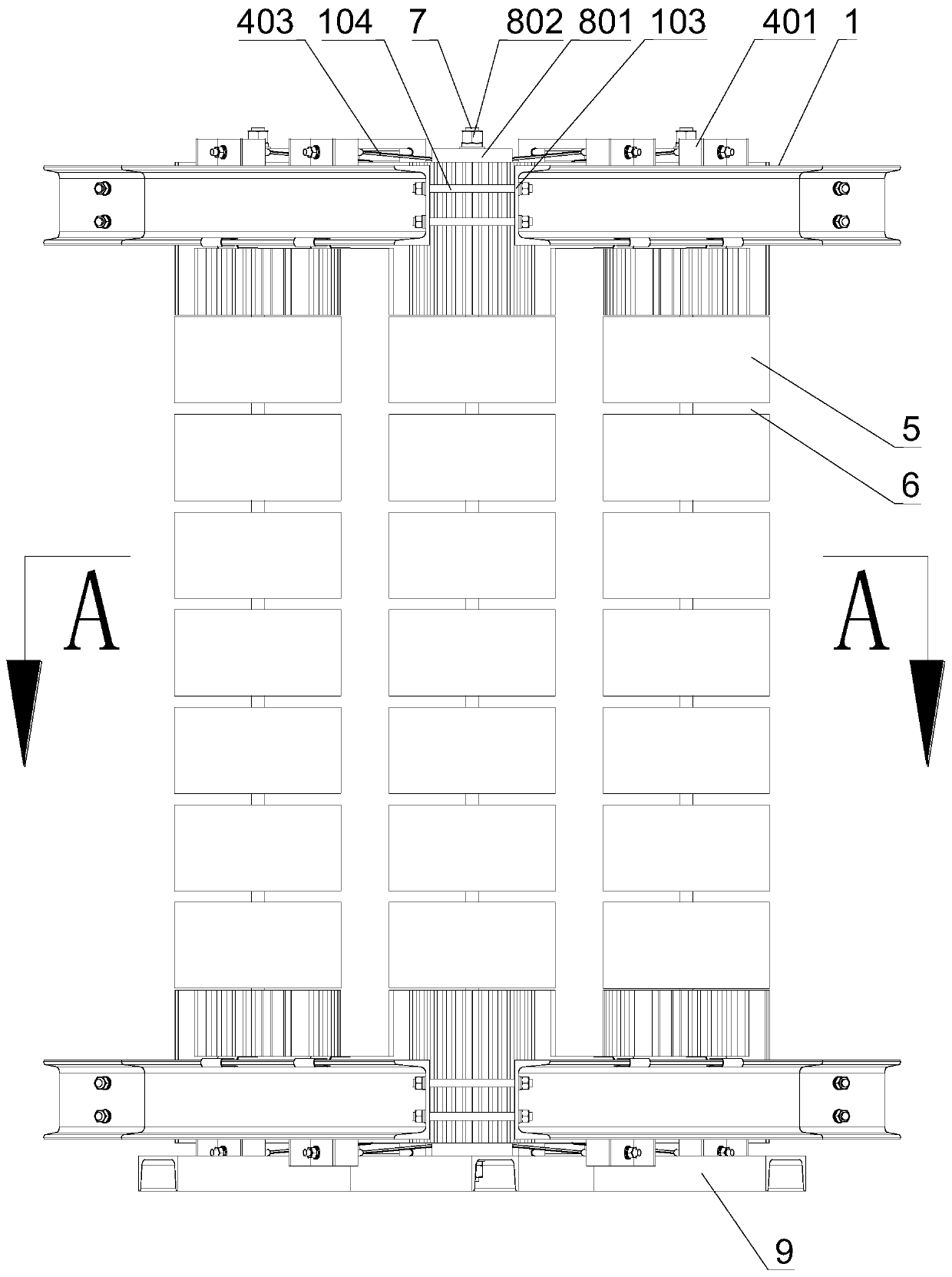

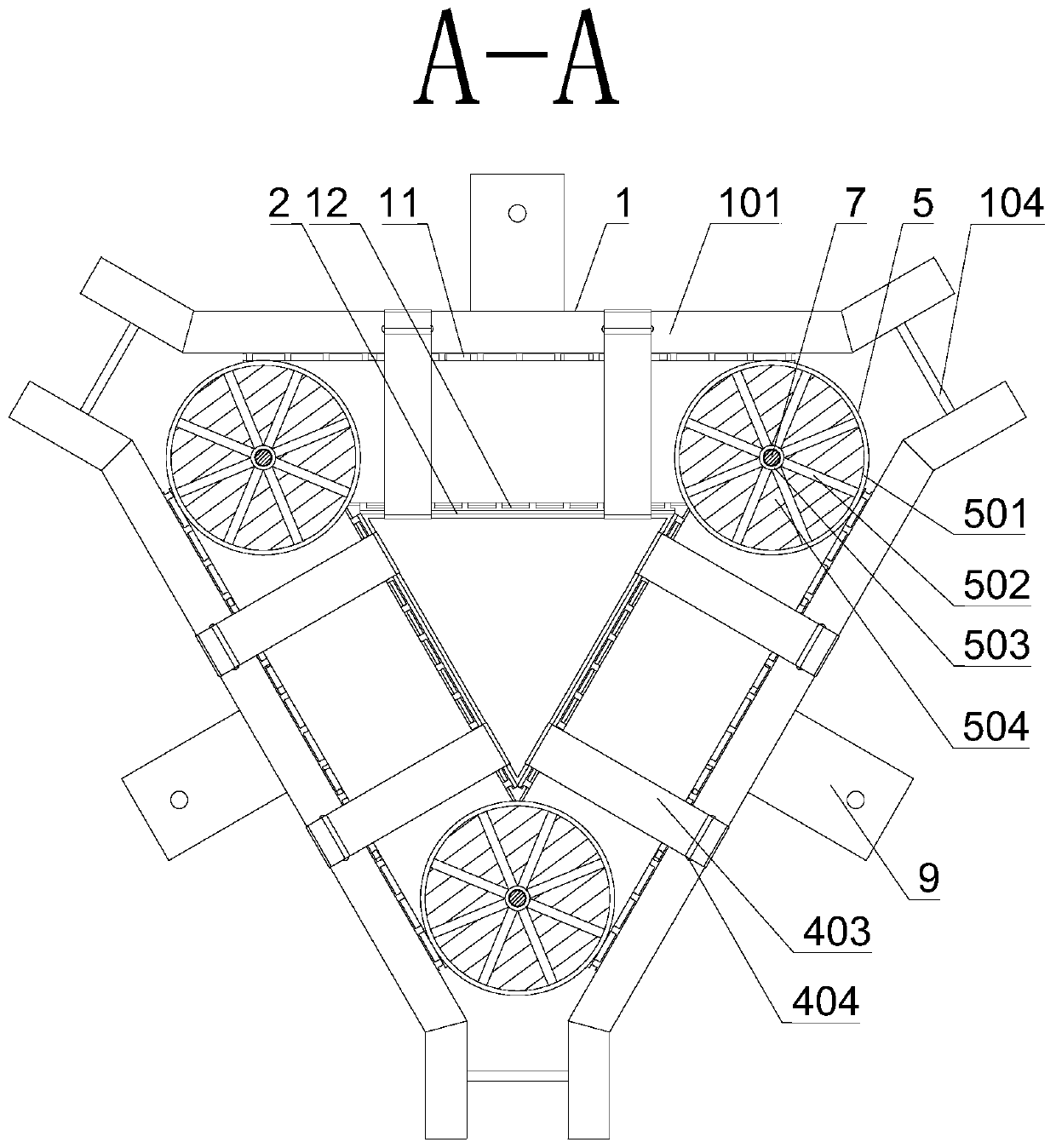

[0048] A preferred embodiment of the present invention provides a three-phase three-dimensional laminated iron core of a three-phase reactor, including an upper iron yoke, a lower iron yoke, a core column located between the upper iron yoke and the lower iron yoke, and A fixing mechanism for fixing the iron yoke and the core column, the upper iron yoke and the lower iron yoke are triangular three-phase iron yokes, and the three-phase iron yokes include three single-phase iron yokes, three single-phase iron yokes An equilateral triangle is formed by splicing two by two, and an insulating plate is arranged at the butt joint edge of the single-phase iron yoke spliced in two, and the thickness of the insulating plate is 1 mm;

[0049] The number of the core column is three, which correspond to the three corners of the three-phase iron yoke. Gap pads 6 are alternately placed, and the through-core screw 7 is a magnetically isolated stainless steel screw, and epoxy cloth pipes are ...

Embodiment 2

[0067] This embodiment is on the basis of embodiment one, such as Figure 9 As shown, the difference is that the iron yoke laminations 3 include n rectangular laminations stacked successively from the outside to the inside, and the laminations superimposed on the i-th layer correspond to the edges of the next lamination. The angle between the connecting line and the horizontal direction is 30°, and the edge of the laminated sheets of the jth layer and the number of layers before and after it is tangent to the axial direction of the through-hole screw 7, wherein, the relationship between n and i, j is: i, j and n are all integers greater than 1, and the edge is the edge close to the adjacent single-phase iron yoke; for the laminations that do not exceed the i-th layer, they can be stacked into a cuboid, and the iron yoke of this structure When laminations 3 are superimposed, the operation is simpler.

Embodiment 3

[0069] This embodiment is on the basis of embodiment one, such as Figure 10 As shown, the difference is that the iron yoke laminations 3 include n laminations stacked one by one from the outside to the inside, and the connection between the laminations stacked on the i-th layer and the corresponding points on the edge of the next lamination The angle between the horizontal line and the horizontal direction is 30°, and the edges of the jth layer and the laminated sheets of the same number of layers before and after are tangent to the axial direction of the core screw 7, wherein the relationship between n and i, j is: i, j and n are all integers greater than 1, and the edge is the edge close to the adjacent single-phase iron yoke; for the laminations that do not exceed the i-th layer, they can also be stacked into other structures, such as inverted Isosceles ladder shape, the edges of the laminations that do not exceed the i-th layer are inscribed with a circle, and the diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com