Pipeline robot

A pipeline robot and operating mechanism technology, applied in the field of robotics, can solve problems such as poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

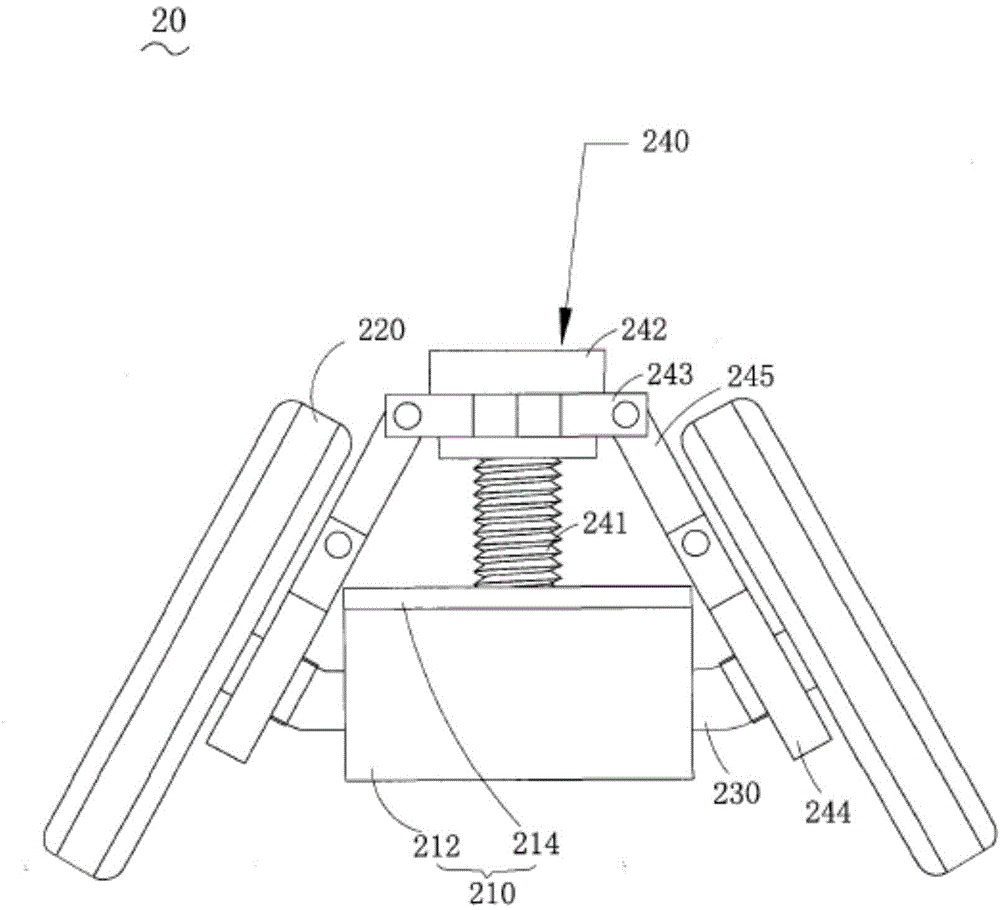

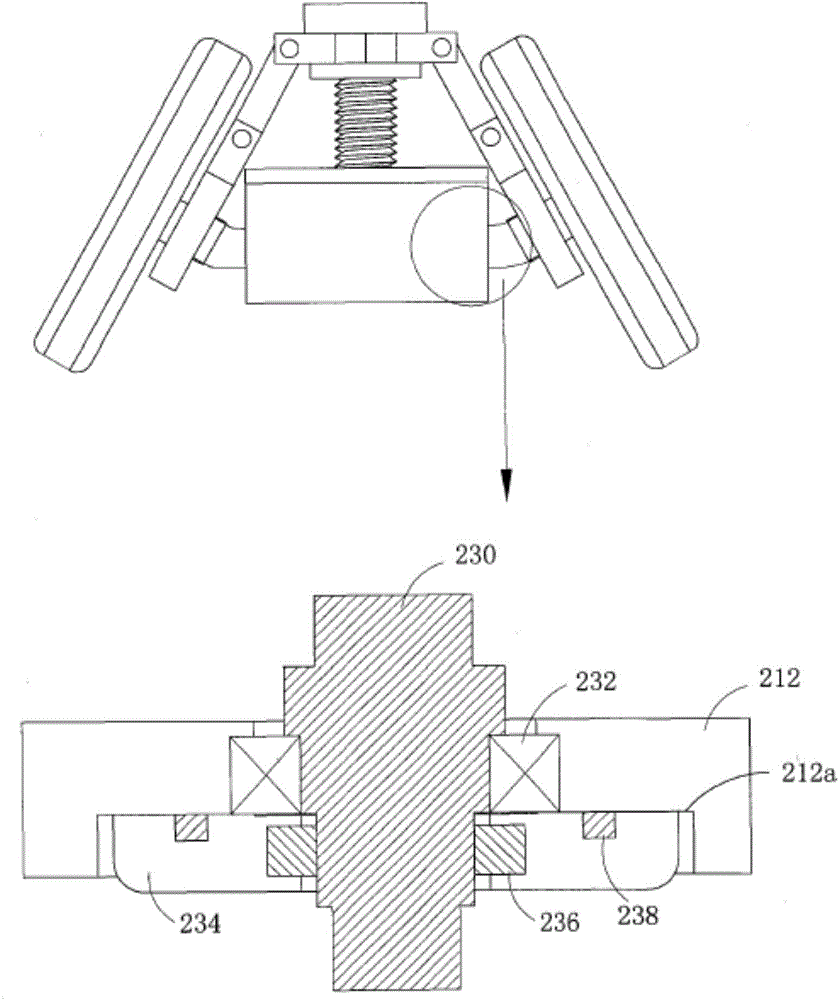

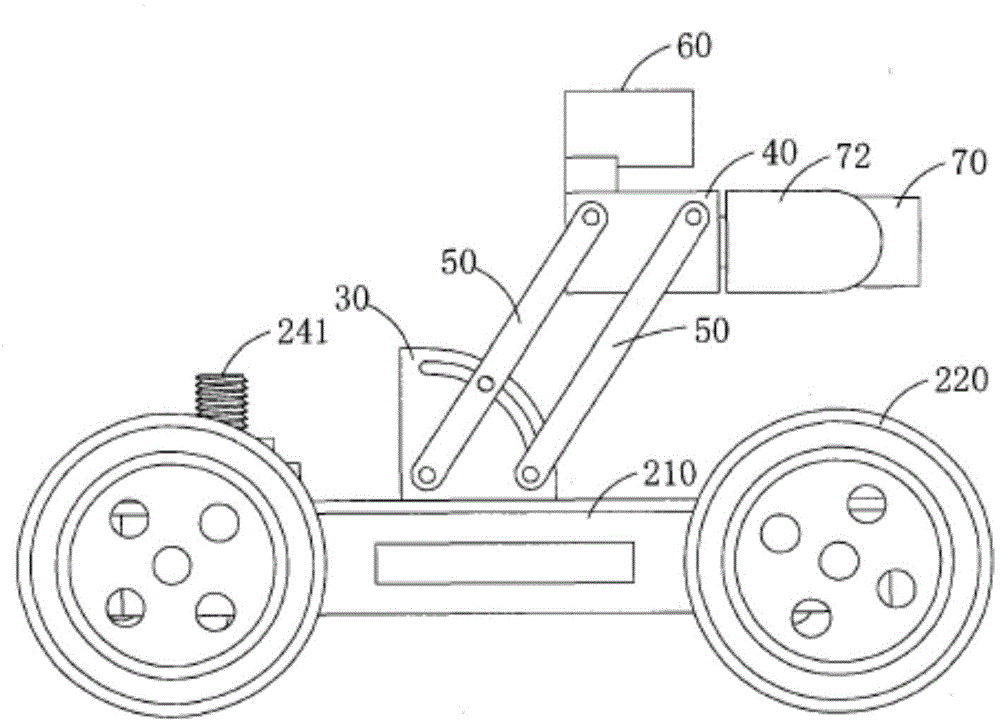

[0027] Pipeline inspection robots generally include two parts, namely the remote monitoring system on the ground and the robot body in the pipeline. The communication methods between the two are wireless and wired. When using wireless communication, since there is no cable, the detection efficiency is high, but the image transmission effect is poor, and it is greatly affected by interference, and the mobile carrier needs to have its own battery, so the voyage distance is limited to a certain extent. In addition, once the mobile carrier of the robot body fails, it is necessary to manually enter the pipeline to recover the pipeline to detect the robot, which is difficult to recover. When the wired method is used, the quality of the communication signal is good, and the power supply can be supplied through the cable, which increases the sailing distance; however, due to the increased resistance and gravity of the cable, the traction force of the mobile carrier is required to be re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com