Rapid supporting lug

A foot-supporting and fast technology, applied in the direction of supporting machines, mechanical equipment, machines/stands, etc., can solve the problems of wasteful work efficiency, reduction, and inability to achieve rapid lifting, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

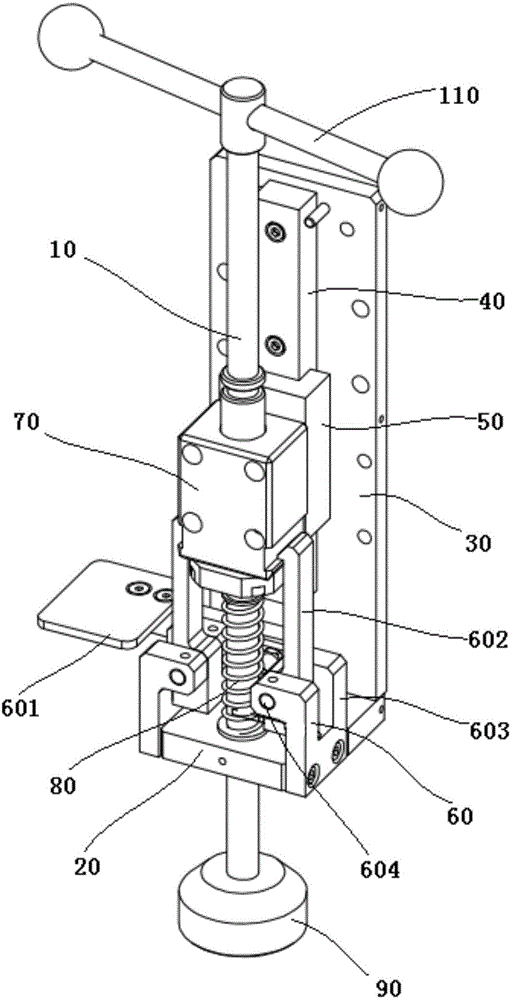

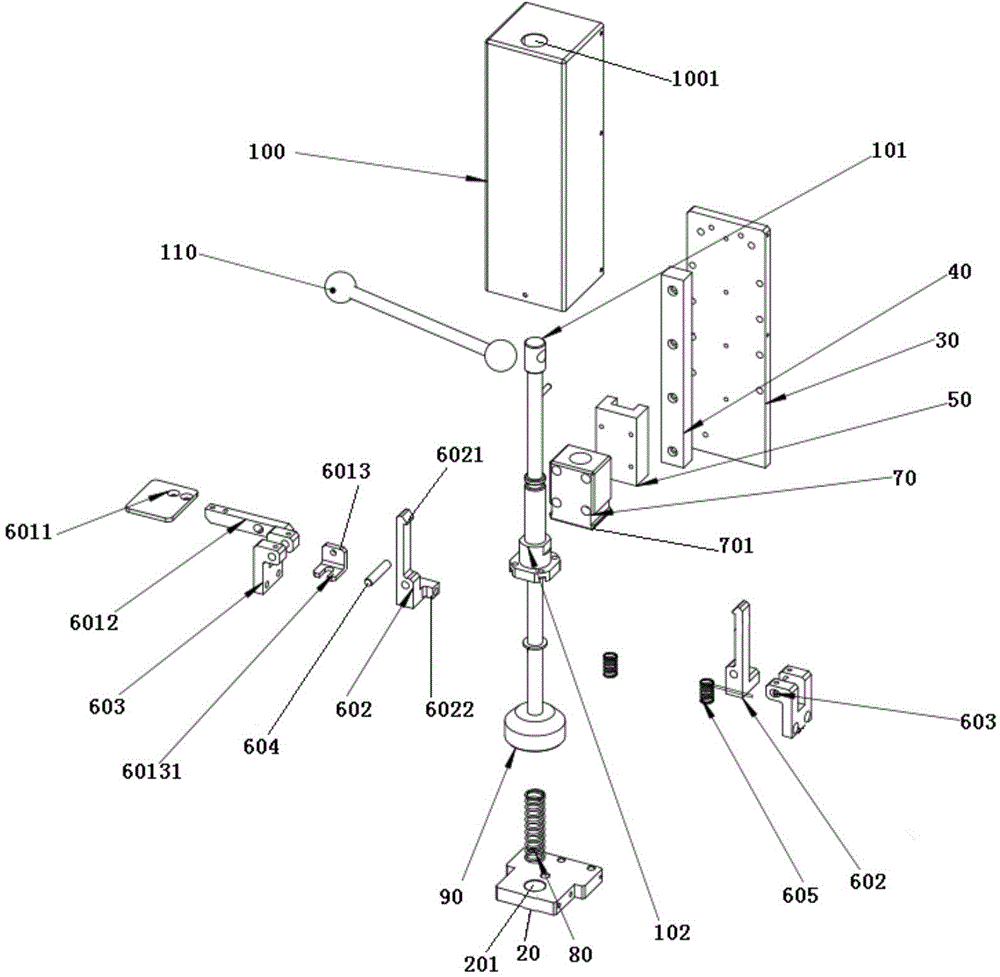

[0029] like figure 1 and figure 2 As shown, a quick support foot includes a lead screw 10, a bottom plate 20 and a side plate 30 vertically arranged on one side of the bottom plate, and the side plate is provided with a slide rail 40 and a slide rail slidably connected Slider 50; the base plate is provided with a relief opening 201, and the peripheral side of the relief opening is provided with a hook device 60; the lead screw includes a screw rod 101 and a nut 102 matched therewith, on the nut Set the inherent screw fixing block 70, the screw fixing block is fixedly connected with the slider, the screw is covered with a compression spring 80, and the screw is installed in the relief opening, so that the compression spring is positioned Between the nut and the bottom plate, a foot cup chassis 90 is provided at the lower end of the screw, and the hooking device can hook the screw fixing block and disengage from the screw fixing block. In this way, when in use, the side plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com