Backlight module and display device

A backlight module and adhesive technology, applied in lighting devices, fixed lighting devices, lighting device parts and other directions, can solve the problems of film layer structure deformation, uneven heat, wrinkles and other problems, and achieve the effect of avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0027] The present invention provides a solution to the problem of layer deformation caused by uneven heat generation in existing display devices.

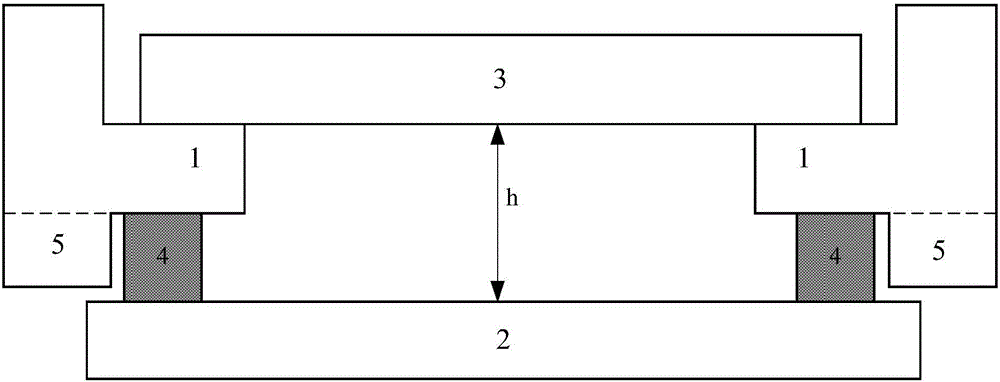

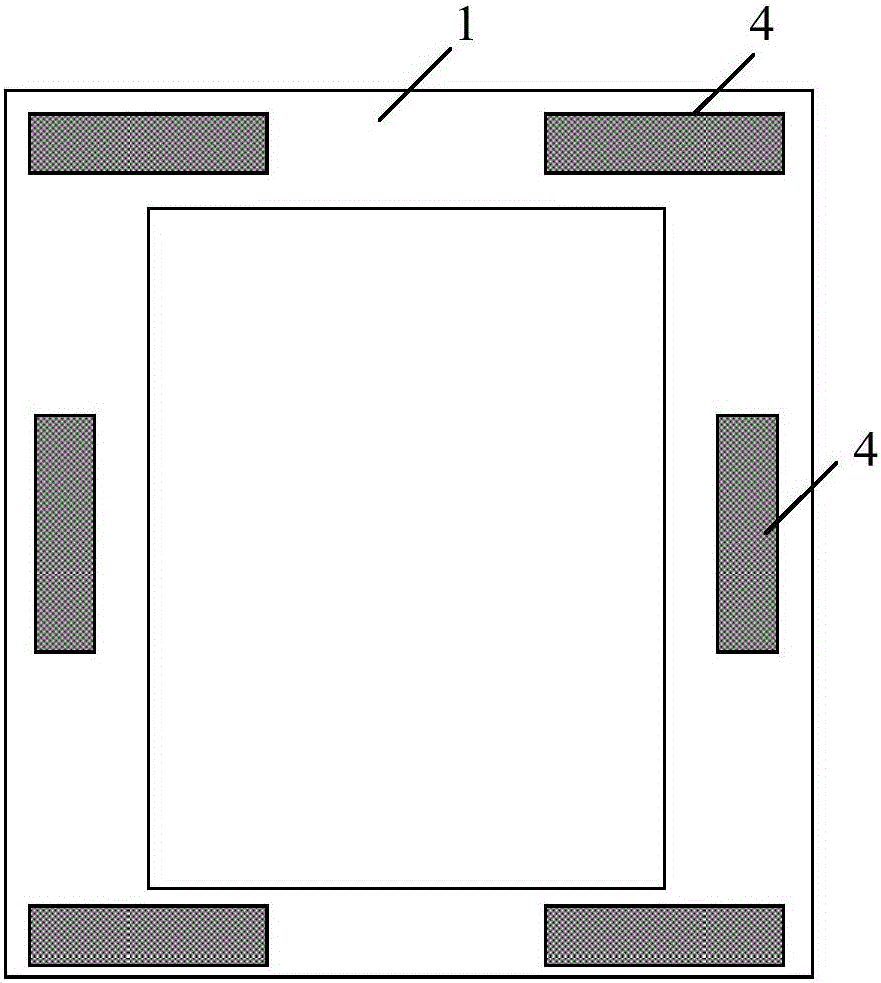

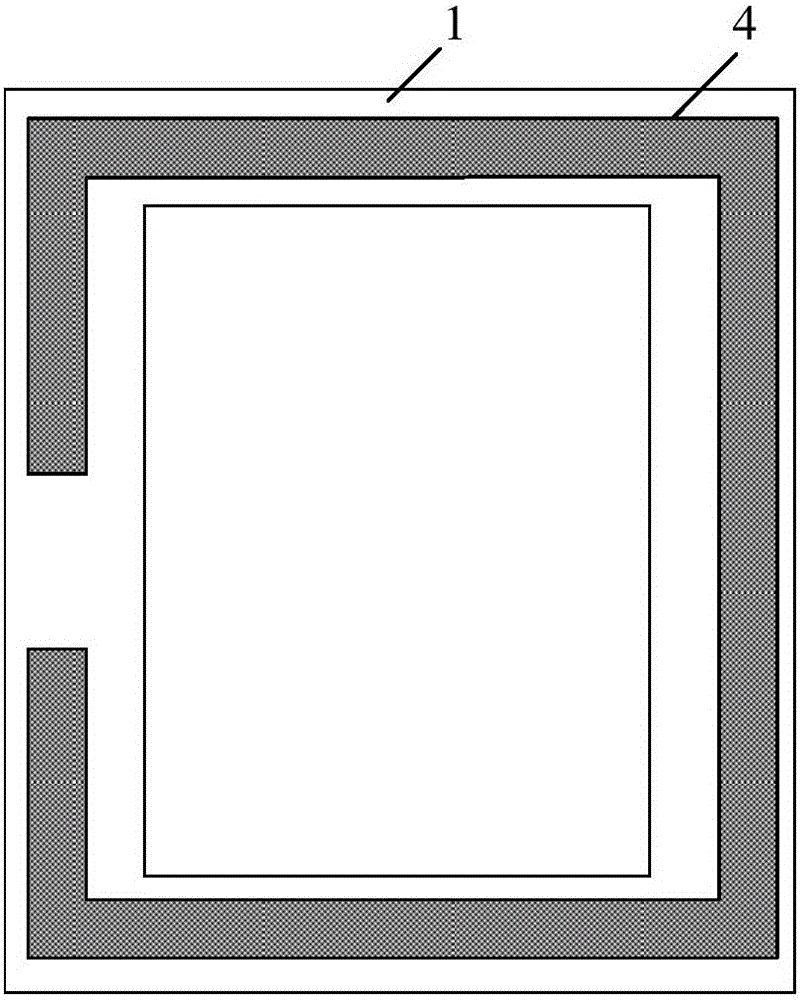

[0028] On the one hand, if figure 1 As shown, the embodiment of the present invention provides a backlight module, including: a plastic frame 1, a reflective film 2, and an optical component 3 (the optical component includes a plurality of functional film layers such as a light bar and a circuit). in,

[0029] The optical component 3 is set in the accommodation area formed by the top of the plastic frame 1, and a back glue 4 is arranged on the bottom side of the plastic frame 1, and the reflective film 2 is fixed to the plastic frame 1 through the back glue 4, so as to be separated from the optical componen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap