Sliding-block-type liquid level metering device

A metering device, slider-type technology, applied in the direction of the buoy liquid level indicator, etc., can solve the problems of the liquid level gauge float being stuck and unable to turn over, potential safety hazards, degaussing of the magnetic poles of the display, etc., to solve the inconvenience of use and potential safety hazards, and improve The effect of operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and examples.

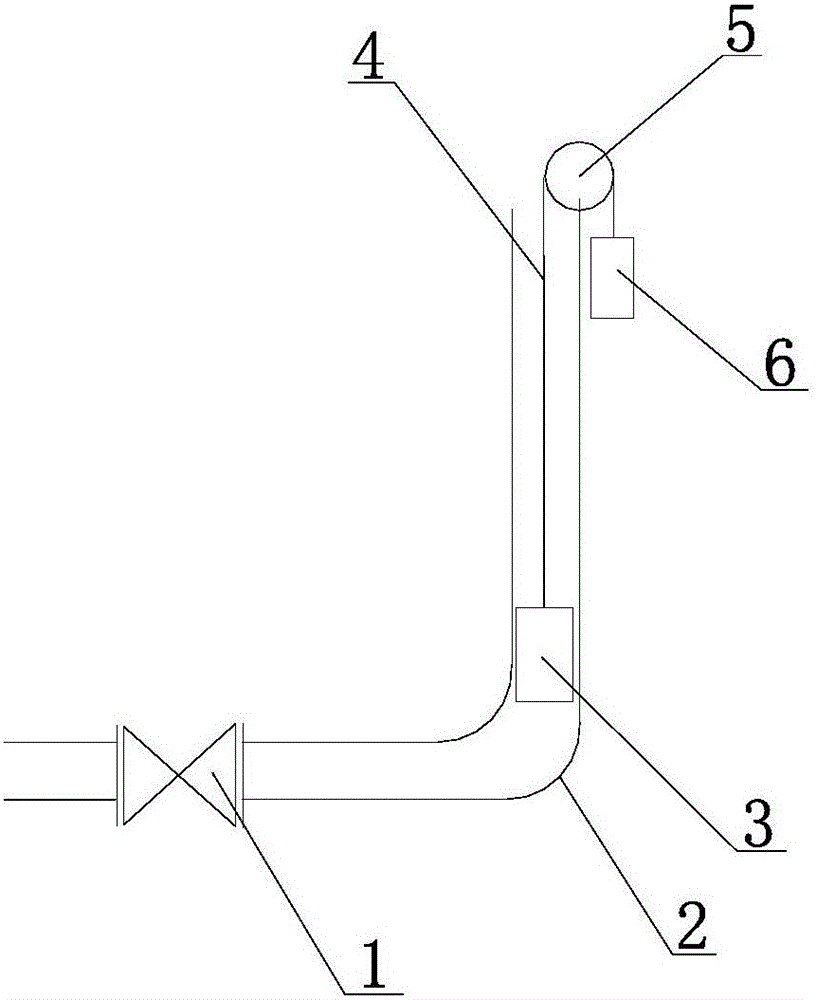

[0014] Such as figure 1 As shown, the present invention provides a slider type liquid level measuring device, which includes a cylinder body 2 with an L shape and openings at both ends, a buoy 3 arranged in the cylinder body 2, and fixed on the cylinder body 2 The directional pulley 5 at the opening of one end of the body 2, the gate valve 1 opened at the other end of the cylinder 2, and the slider 6; the buoy 3 is connected with the slider 6 through a nylon rope 4, and the nylon rope 4 is wound on the directional pulley 5; the outside of the cylinder 2 is provided with a liquid level scale at a position close to the slider.

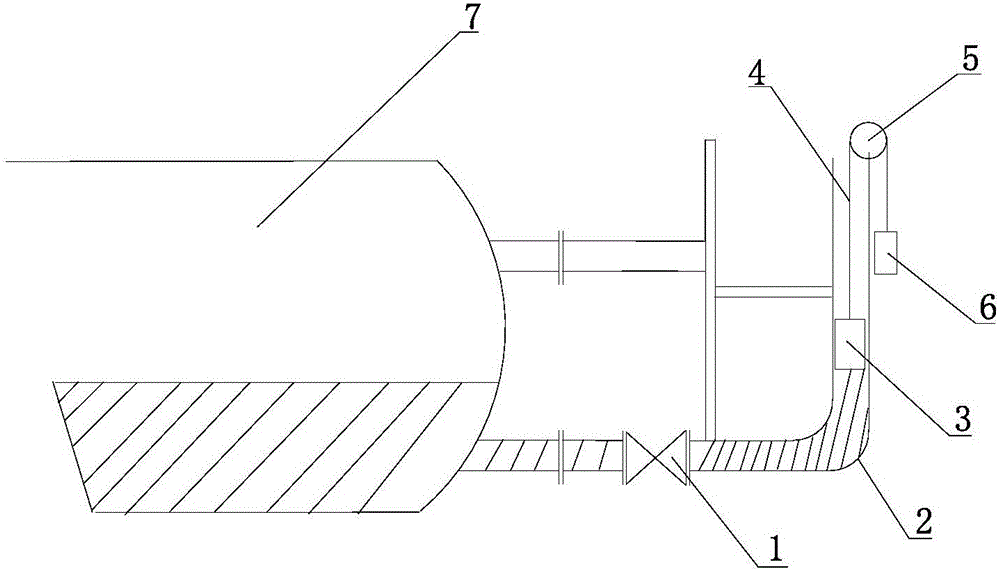

[0015] Such as figure 2 As shown, when the present invention is in use, one end of the cylinder body 2 is connected to the sewage tank 7 by using a flange, and then other parts (such as a fixed connecting rod, a support column, et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com