Flame retardant material performance testing device

A technology of fire-retardant materials and detection devices, which is applied in the direction of chemical analysis by combustion, can solve the problems of complex testing process and inconsistency with actual requirements of flame-retardant performance, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

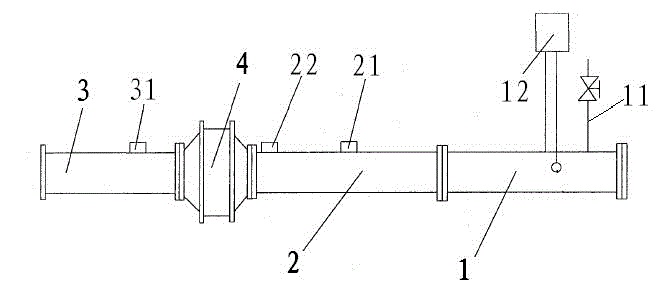

[0014] like figure 1 As shown, the fire retardant material performance detection device of the present embodiment includes detonating tube 1, flame accelerating tube 2, fire retardant tube 4 and observation section 3 connected in series in sequence, and is characterized in that: described fire retardant tube 4 is filled with The fire retardant material, the fuel pipeline 11 and the detonator 12, and the flame acceleration tube 2 are provided with a flame speed sensor 22 and a pressure sensor 22 .

[0015] In this embodiment, the observation section 3 is provided with a flame detector 31 near the end of the fire arresting pipe 4 .

[0016] In this embodiment, the diameters of the detonating tube 1 , the flame accelerating tube 2 and the observation section 3 are 0.6-0.75 times that of the flame arresting tube 4 .

[0017] In this embodiment, the detonating tube 1 and the flame accelerating tube 2 are made of stainless steel with a thickness of 7-20mm.

[0018] In this embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com