Switch power source and bus capacitor voltage control method used for switch power source

A bus capacitor and switching power supply technology, which is applied in the field of switching power supplies, can solve the problems that the bus capacitor cannot be miniaturized and the proportion of the bus capacitor is increasing, so as to shorten the discharge time, realize the miniaturization, and reduce the capacitance value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

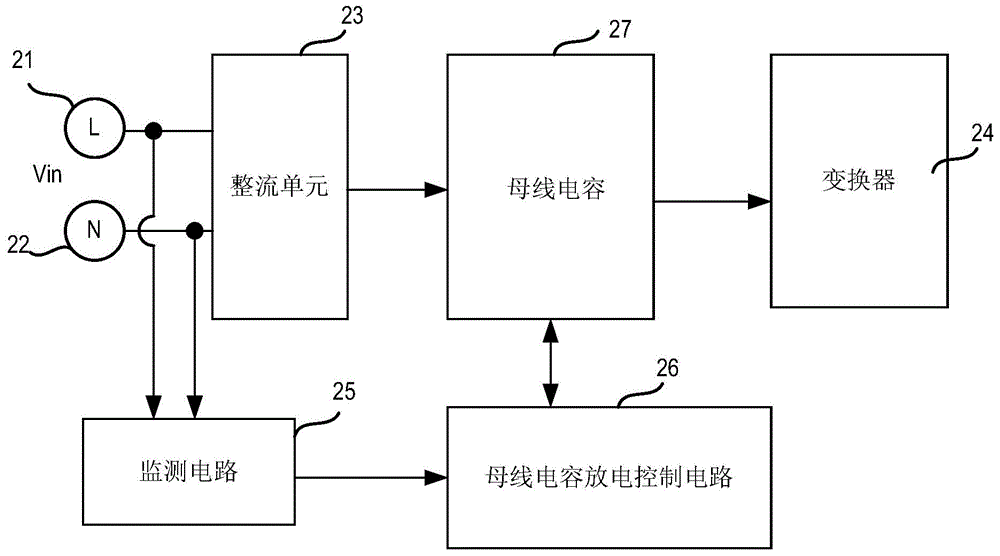

[0025] figure 2 A circuit block diagram of an embodiment of the switching power supply of the present application is schematically shown, and the switching power supply includes: a rectifying unit 23 , a bus capacitor 27 , a converter 24 , a monitoring circuit 25 and a bus capacitor discharge control circuit 26 .

[0026] The rectification unit 23 includes an AC side and a DC side, and the rectification unit 23 is configured to convert the AC voltage input from the AC side into a DC voltage output from the DC side. The AC side includes a first AC voltage input terminal 21 and a second AC voltage input terminal 22, and these two input terminals are used for receiving an input AC voltage Vin. For example, one of the first AC voltage input terminal 21 and the second AC voltage input terminal may be connected to the neutral line (N), and the other may be connected to the live line (L). The rectification unit 23 may be, for example, a rectification element such as a rectification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com