Method for repairing sandwich panels made of composite materials involving the creation of core or of mould using stereolithography

A repair method and composite material technology, which is applied in the field of repair composite sandwich panels, can solve problems such as bad customer impression, large ecological impact of parts, and high cost of new parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

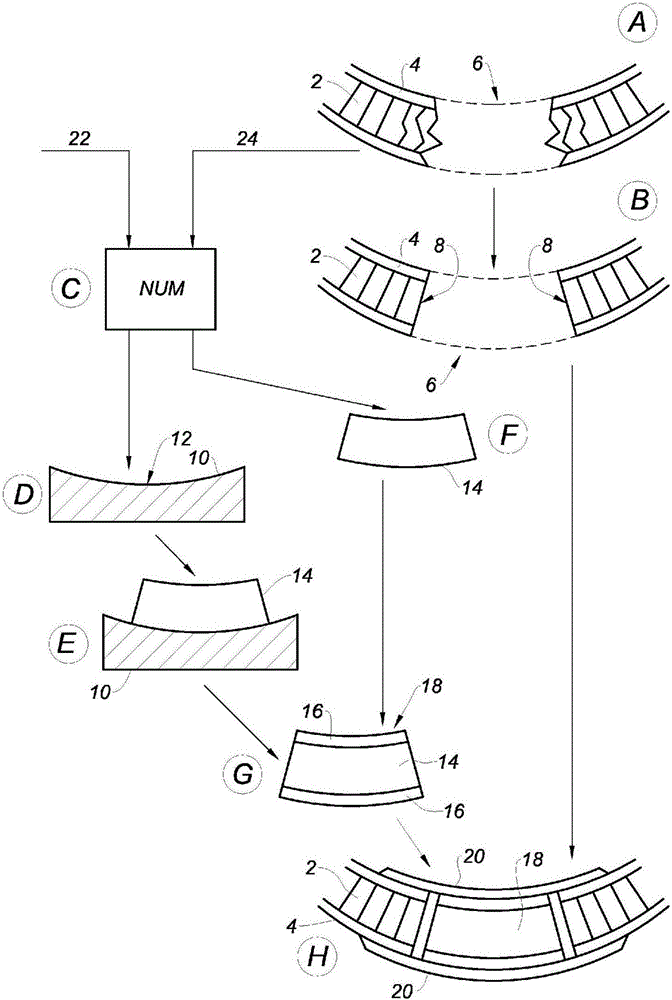

[0028] According to a first embodiment, the next step D consists of making, from the digital file, a mold 10 comprising a smooth inner surface 12 having the same shape as that in the damaged part of the plate by means of stereolithography. The curved section corresponds to the curved section.

[0029] The next step E consists of making the core 14 and / or repairing the skin in the mold 10, using the material and according to known molding methods, covering a surface at least equal in size to the opening 6 of the plate to be replaced; repairing the skin 4 with to be bonded to the core (2, 14).

[0030] According to a second embodiment, instead of the above-mentioned last two steps D, E, in a further step F, the core 14 and / or the skin 4, also obtained by stereolithography methods, are produced directly and are also A bent portion corresponding to the bent portion in the damaged portion of the board is included.

[0031] Stereolithography is a technique also known as rapid prot...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap