telecentric lens

A telecentric lens and lens technology, applied in instruments, measuring devices, optics, etc., can solve problems such as complex manufacturing, difficulty in obtaining optimal alignment of lens components, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

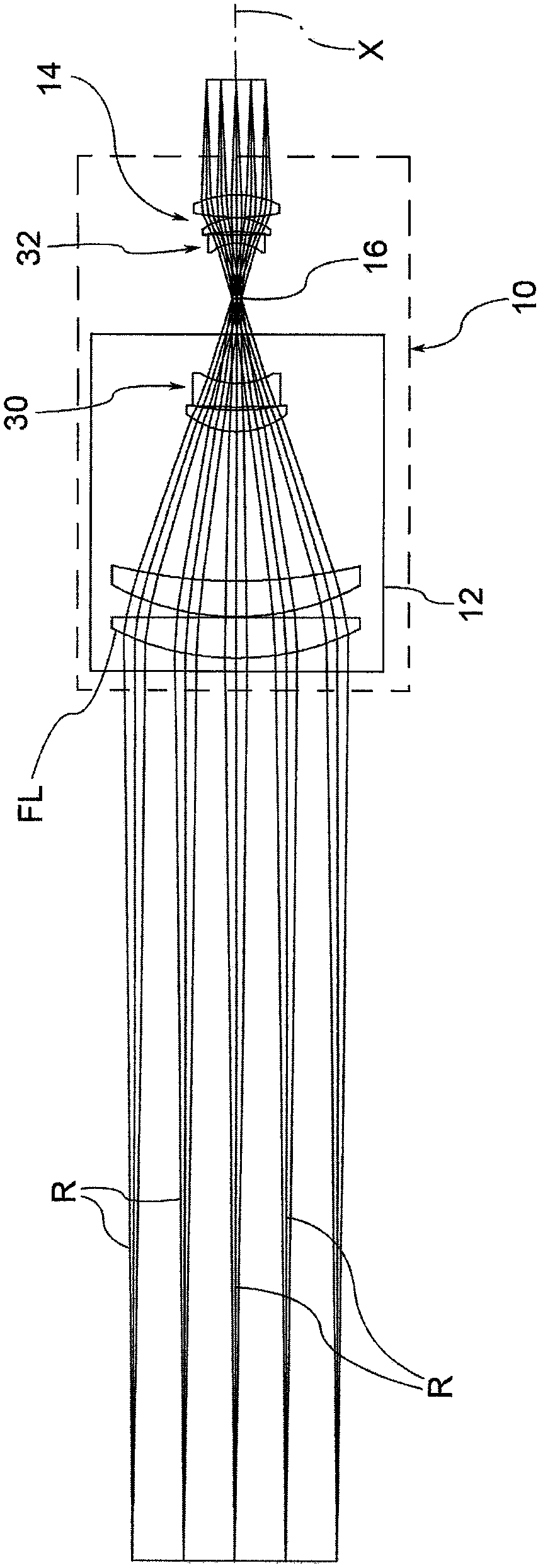

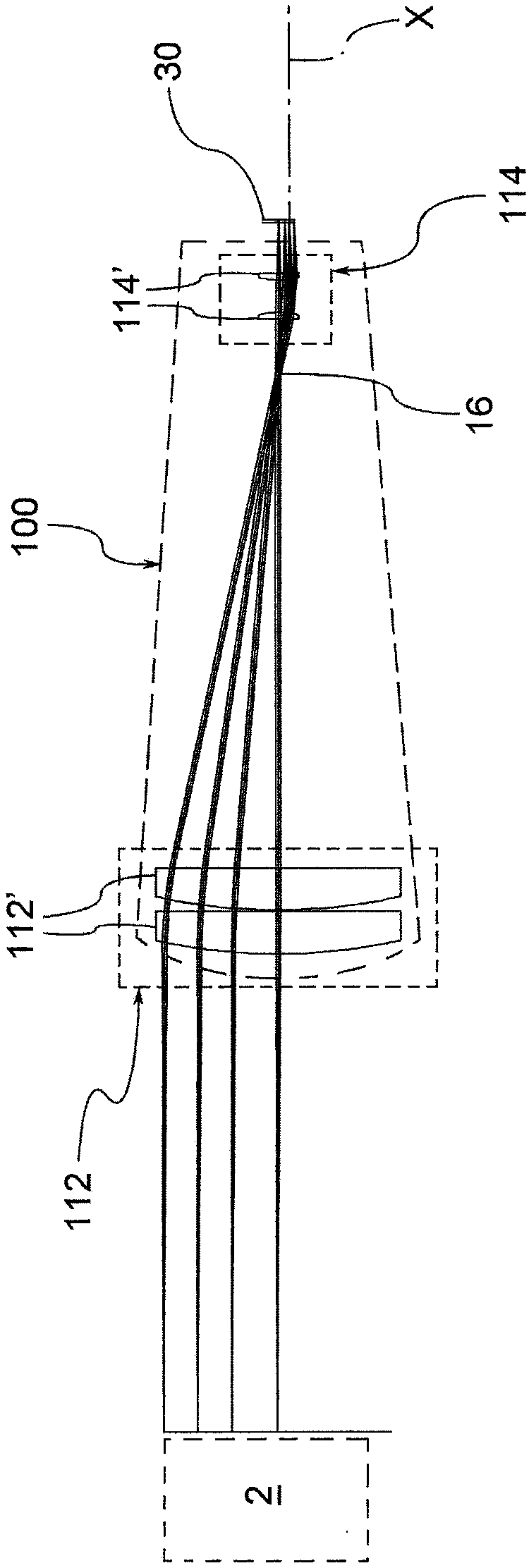

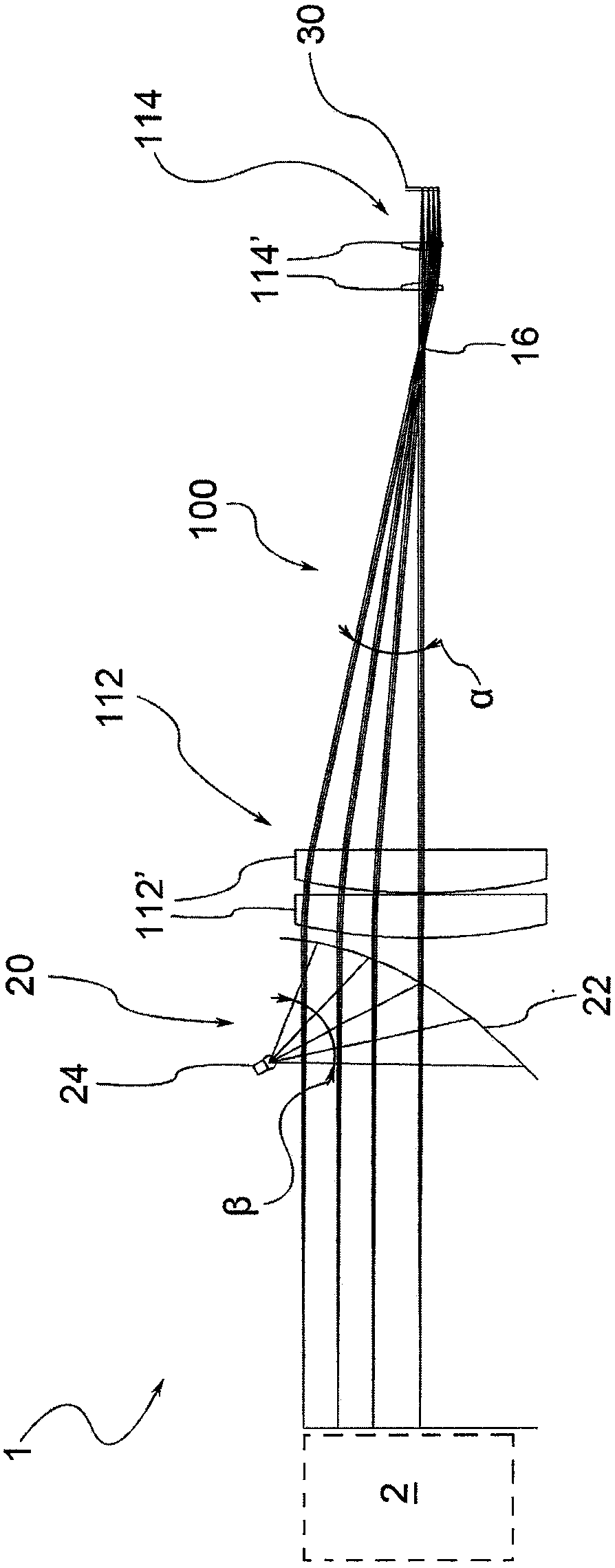

[0014] refer to figure 2 , the telecentric lens 100 according to the invention has a principal optomechanical axis X and comprises a front optical group 112 adapted to receive rays from the object 2 to be observed and a front optical group 112 adapted to transmit said rays to the sensor 30 of the vision device Rear optical group 114 . A telecentric lens aperture (indicated by reference numeral 16 ) is located between the front optical group 112 and the rear optical group 114 .

[0015] The front optical group 112 is intended to collect the rays from the object 2 in such a way that the axis of each ray cone is parallel to the chief beam by virtue of the position of the aperture 16 itself in the focal plane of the front optical group 112 Mechanical axis X. On the other hand, the rear optical group 114 collects the radiation passing through the aperture 16 and focuses the radiation on the sensor 30 to allow image formation. According to a preferred embodiment of this optical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com