Cotton stalk pulling mechanism

A technology for pulling out cotton stalks and cotton stalks, which is applied in the field of cotton stalk pulling devices, which can solve problems such as difficult cutting, grass entanglement, and high energy consumption, and achieve the effect of simplifying the structure and preventing the blades from tangling grass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

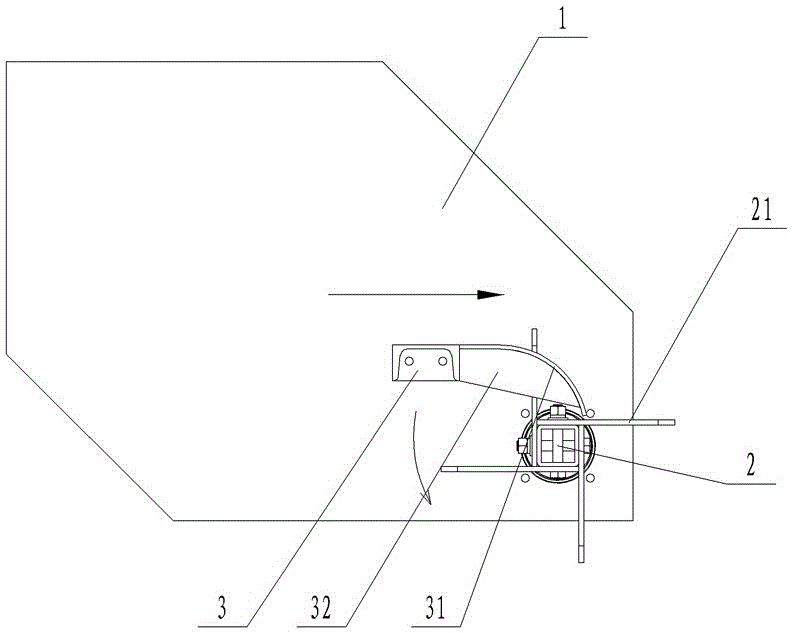

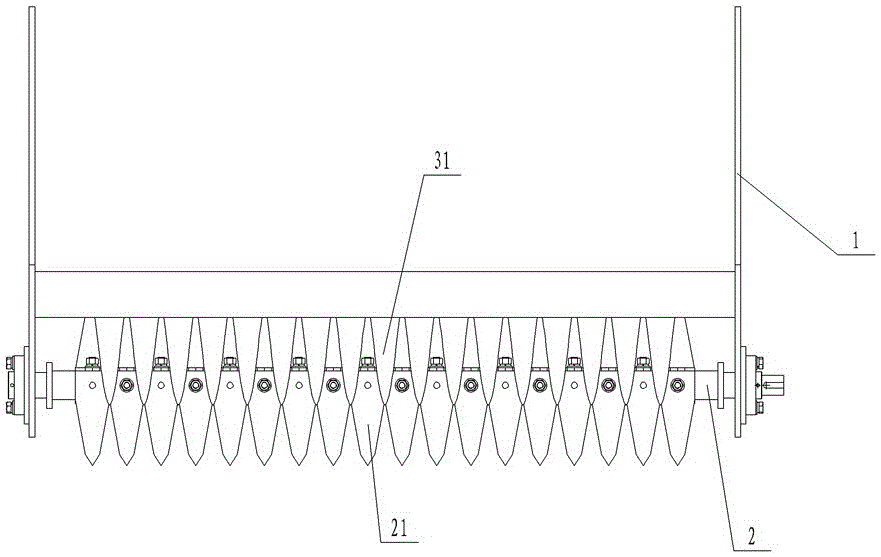

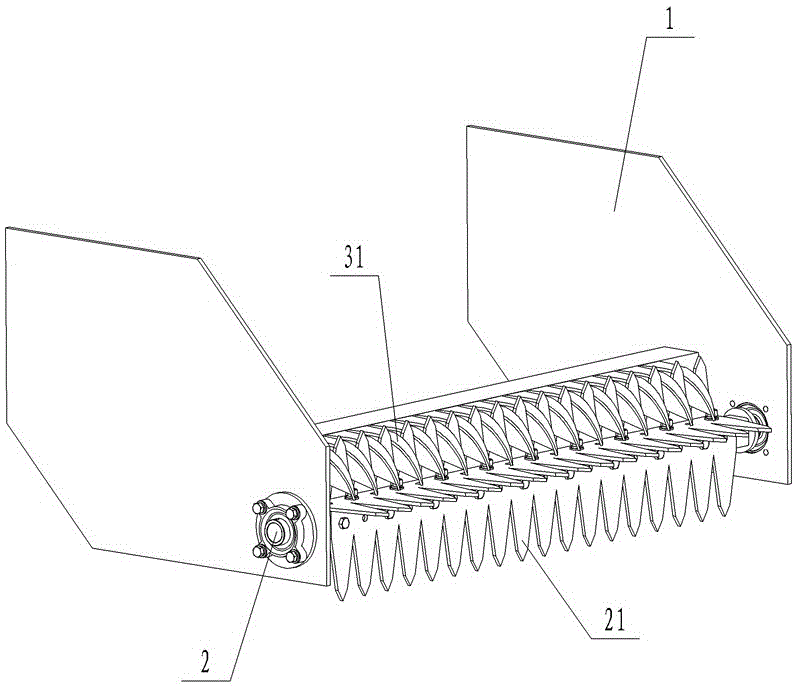

[0018] The mechanism for pulling out cotton stalks in this embodiment, such as figure 1 , figure 2 and image 3 As shown, it includes the stalk pulling tooth roller shaft 2 arranged on the frame 1 and the stalk retracting tooth seat 3 fixed on the frame 1. The stalk tooth roller shafts are arranged relative to each other. The stalk puller teeth 21 are fixed on the stalk puller tooth roller shaft 2, and a plurality of stalk puller teeth 31 are fixed on the stalk puller tooth seat 3. Between two adjacent stalk puller teeth 31 V-shaped notches are formed. Reinforcing ribs 32 are fixed on the stalk teeth 31 .

[0019] Each stalk-removing tooth 31 is an arc-shaped tooth protruding forward and downward, the outer circular surface of the arc-shaped tooth protrudes forward and upward, and the front end of the stalk-removing tooth 31 protrudes from the forward and downward position to pass over the stalk pulling tooth roller Axis 2 centerline.

[0020] When the stalk tooth roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com