A special connecting piece for milking parlor fence

A special connection and milking parlor technology, applied in applications, animal houses, animal husbandry, etc., can solve problems such as large impact, increased maintenance costs, cutting and cutting processing errors, etc., to increase service life and save Maintenance cost, effect of enhanced fastening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

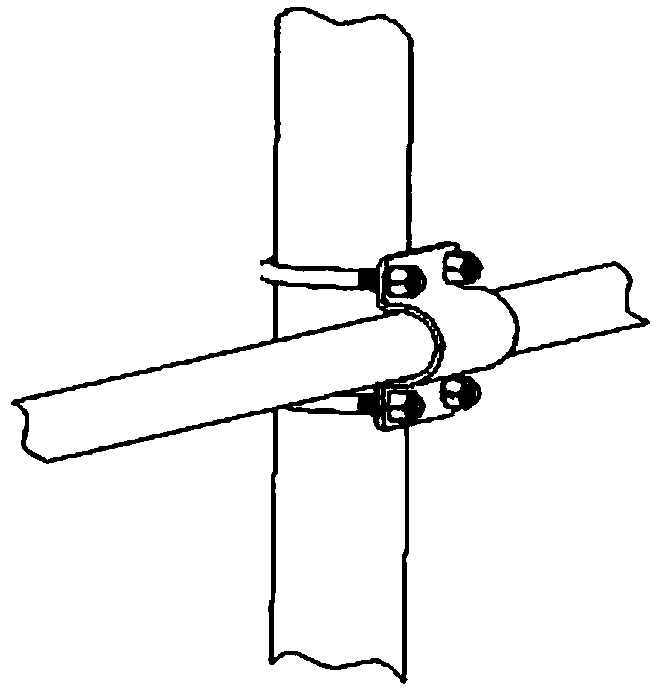

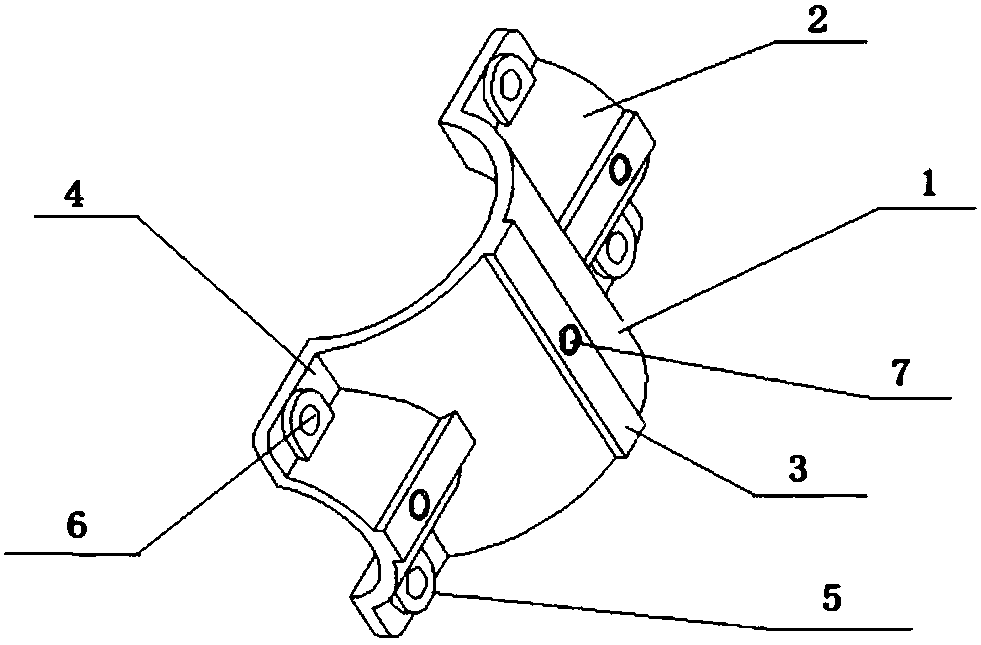

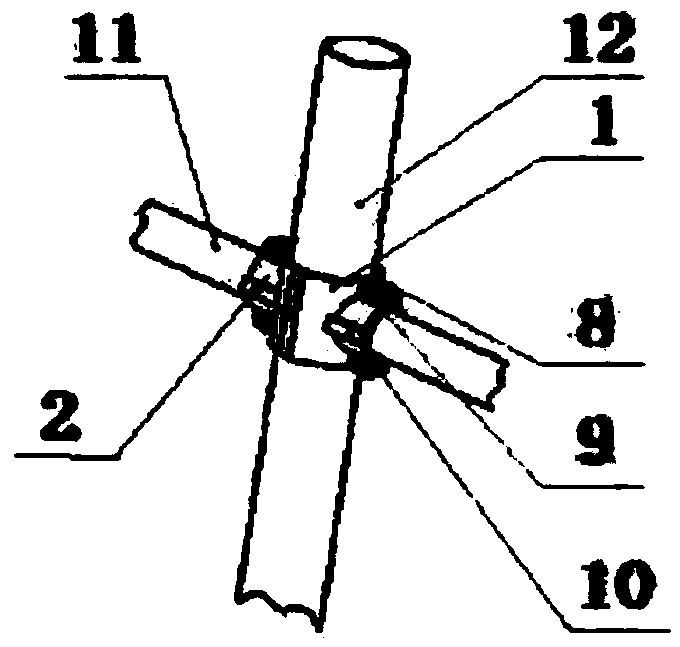

[0034] During installation, when the pre-embedded column 12 and the horizontal horizontal tube 11 are in the shape of a cross, they are connected by a pair of clamping clamps, and the two clamping column sleeves 1 are opposite to each other. Through the bolt hole 6 of the bolt boss 5 on the platform 4 on both sides of the horizontal pipe casing 2, lock it with the lock nut 8, fasten the clamp on the embedded column 12, and then elastically connect the horizontal horizontal pipe 11 on both sides. Insert into the horizontal tube casing 2, press the horizontal horizontal tube 11, pass the M10 threaded hole 7 on the screw boss 3 with the hexagon socket set screw 10, and connect and fasten the holding card with the horizontal horizontal tube 11.

[0035] When the pre-embedded column 12 and the horizontal horizontal tube 11 are at a 90° corner, use t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com