Cut tobacco suction band guide rail device of cigarette making machine

A technology of guide rail device and suction ribbon, which is applied in the fields of tobacco, cigarette manufacturing, application, etc., and can solve the problem of affecting the uniformity of the thickness of the tobacco layer of the suction ribbon, hindering the suction effect of negative pressure suction, and easy wear of the center hole and center pin And other problems, to achieve the effect of improving filling and distribution uniformity, good support effect, and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and provides a detailed implementation manner and a specific operation process, but the protection scope of the present invention is not limited to the following implementation. example.

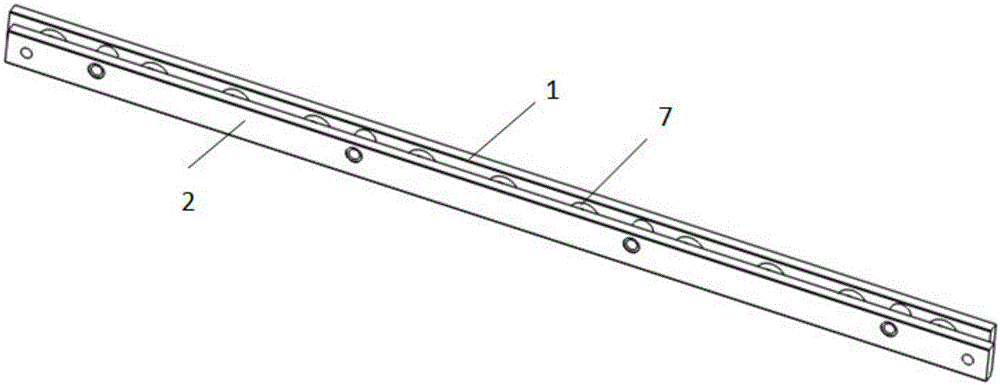

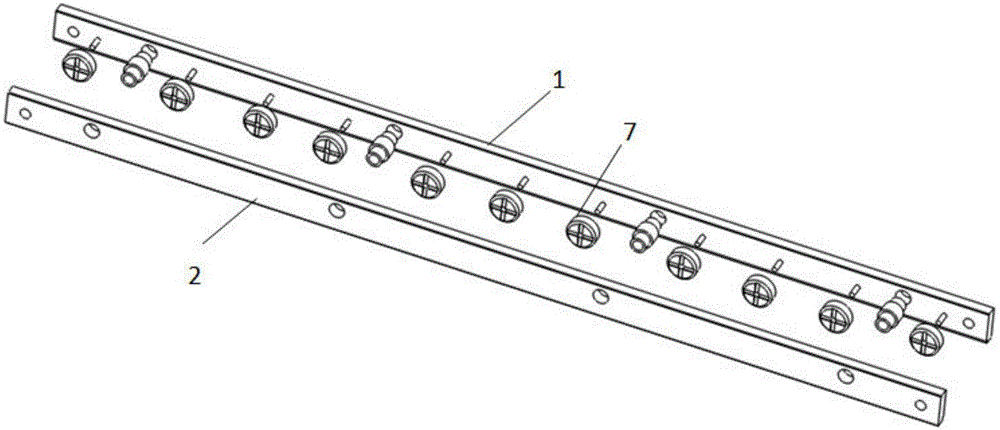

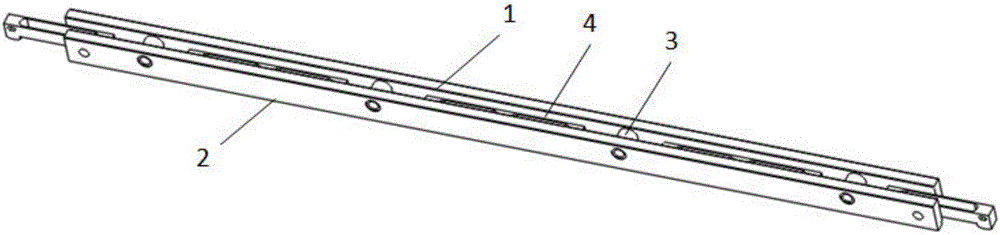

[0029] see image 3 , Figure 4 , This embodiment discloses a cigarette machine suction belt guide rail device, including a plurality of guide rail units, each guide rail unit includes an inner guide rail sheet 1 and an outer rail sheet 2, an inner rail sheet 1 and an outer rail sheet 2 arranged relatively parallel. Connected by the positioning column 3, the middle surface of the positioning column 3 is provided with a protruding annular limit boss, and the inner guide piece 1 and the outer guide piece 2 are respectively fixed on both sides of the annular limit boss of the positioning column 3.

[0030] Also see F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com