Box door auxiliary closing device and method of steam cabinet and steam cabinet

A technology of closing device and box door, which is applied in the field of steam cabinets, can solve the problems of difficult closing of the box door, waste of time, difficulty in use, etc., and achieve the effect of easy closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

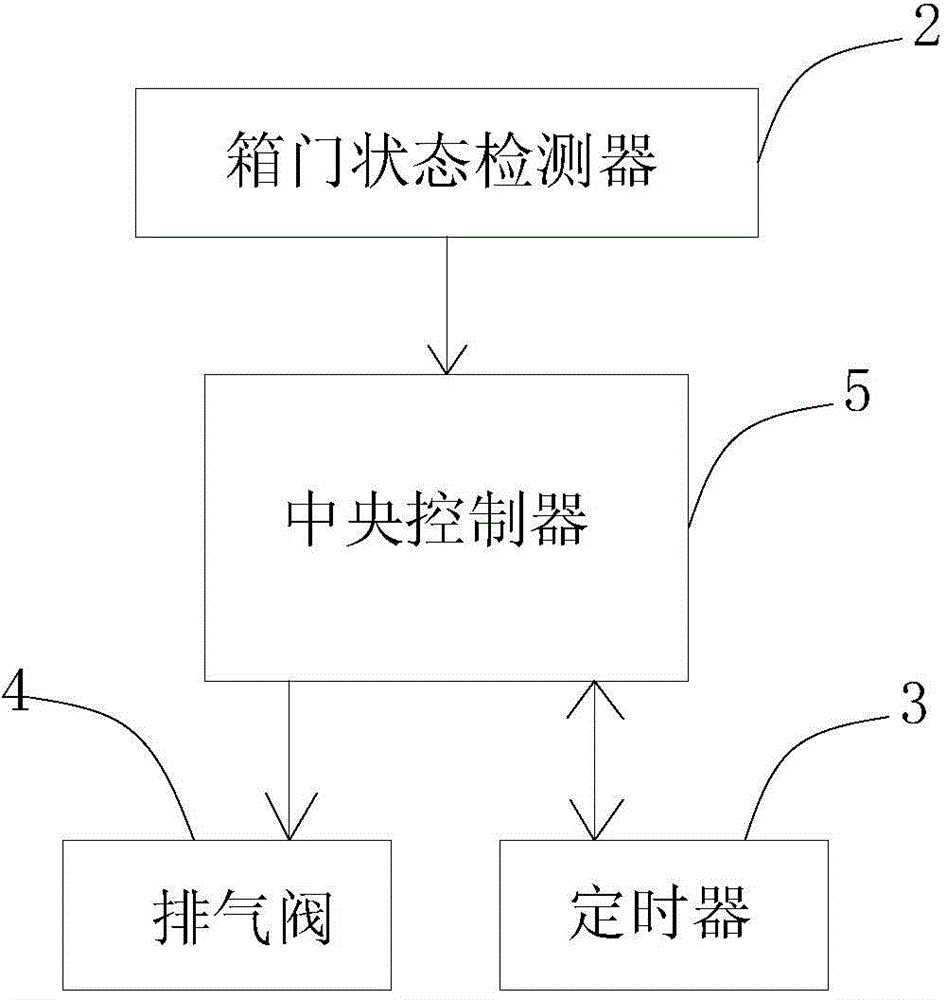

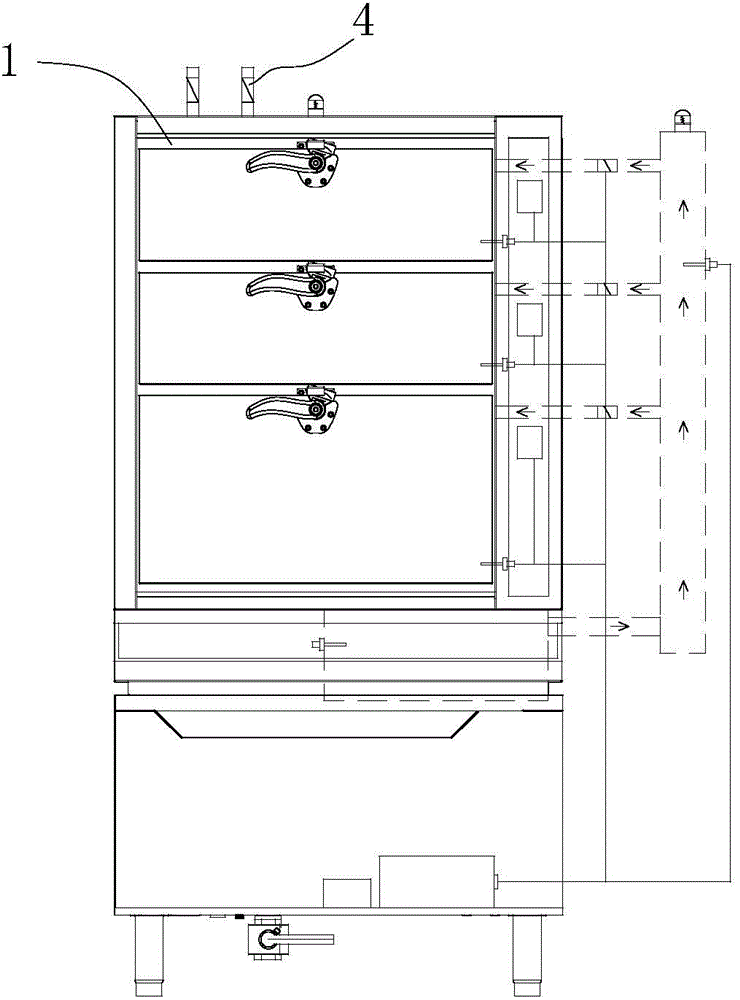

[0020] This embodiment proposes an auxiliary closing device for the door of the steaming cabinet, which combines Figure 1 to Figure 3 As shown, the steaming cabinet wherein includes a plurality of boxes 1, and each box 1 is provided with a door 6, and the auxiliary closing device for the door of the steaming cabinet includes a door state detector 2, a timer 3, at least An exhaust valve 4 and a central controller 5, wherein:

[0021] The door state detector 2 sends a door-closing signal when detecting that the door 6 is closed;

[0022] Send an end signal when the timer 3 finishes counting;

[0023] The exhaust valve 4 is installed in the box body 1;

[0024] The central controller 5 is electrically connected to the door state detector 2, the timer 3 and the exhaust valve 4 respectively, and the central controller 5 controls the exhaust valve 4 to open according to the door closing signal, and starts the timer 3 at the same time. When the timing of the timer 3 ends, the cen...

Embodiment 2

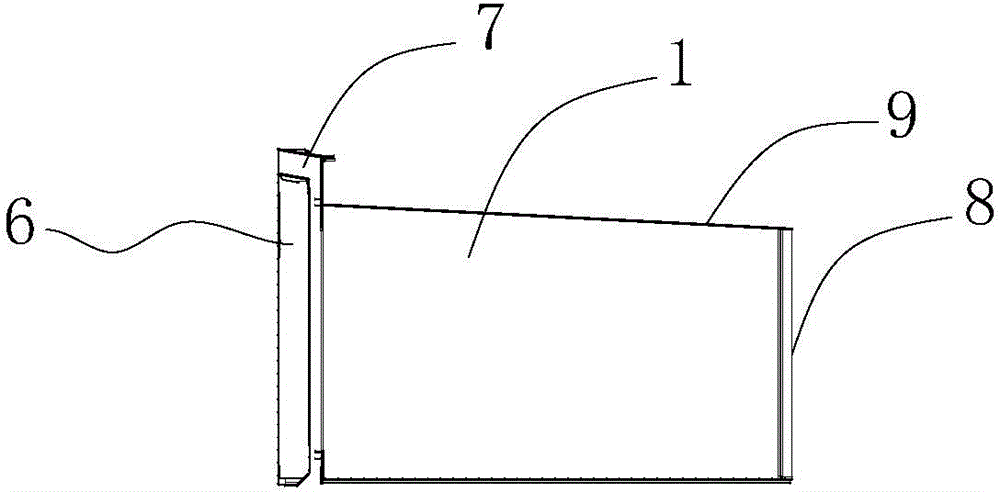

[0029] Present embodiment proposes a kind of steam cabinet, combines Figure 1 to Figure 3 As shown, it includes a plurality of boxes 1, and each box 1 is provided with a door 6, and the steamer also includes the auxiliary closing device for the door of the steamer in Embodiment 1. Wherein, the box body 1 includes a door frame 7, a rear side plate 8 and a top plate 9, the door 6 is arranged on the door frame 7, and the top plate 9 extends from the door frame 7 to the rear side plate 8 and is inclined downward. The upper edge of the door frame 7 extends upwards to the top of the top plate 9 . Since the top plate 9 is inclined downward, and the height of the upper edge of the door frame 7 is higher than that of the rear side plate 8 and the top plate 9, the condensed water on the top of the box body 1 can flow to the rear side of the box body 1, while the inner space of the box body 1 The direction from the box door 6 to the rear side panel 8 gradually decreases. Therefore, whe...

Embodiment 3

[0031] This embodiment proposes an auxiliary closing method for the door of the steam cabinet, combining Figure 1 to Figure 4 As shown, the method includes the following steps:

[0032] Step S1, when the box door state detector 2 detects that the box door 6 is closed, it sends out a door closing signal;

[0033] Step S2, the central controller 5 controls the exhaust valve 4 to open according to the door closing signal, and starts the timer 3 at the same time;

[0034] In step S3, the timer 3 finishes counting and sends out an end signal, and the central controller 5 receives the end signal and controls the exhaust valve 4 to close.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com