Reactor with adjustable interior and exterior temperatures

A technology for adjusting temperature and reactors, which is applied in the field of pressure vessels, can solve the problems of affecting the life of reactors, poor temperature control accuracy, and large temperature changes, etc., to achieve fast absorption or emission of heat, large contact area, and increased heat transfer The effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

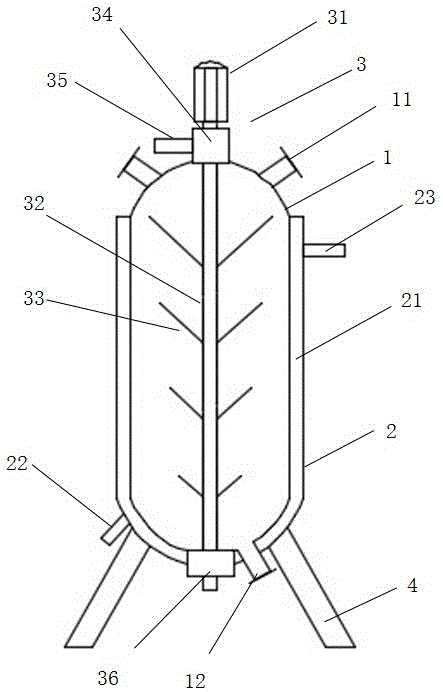

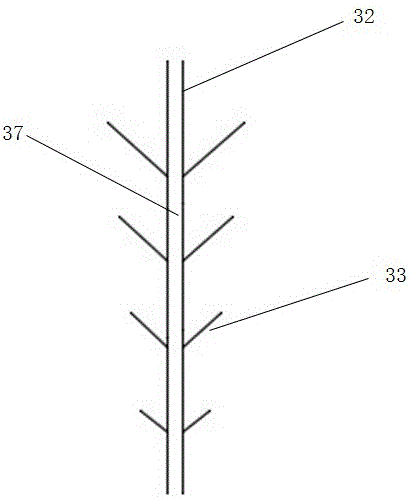

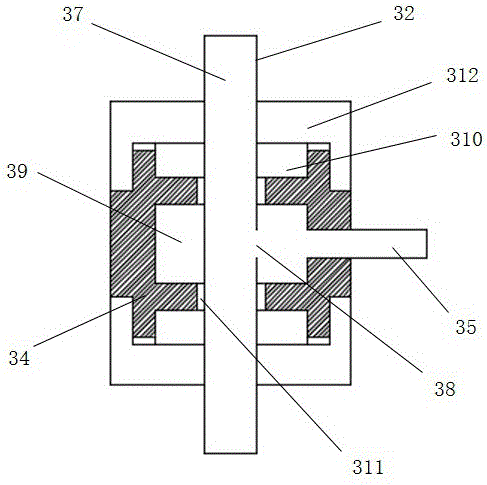

[0020] Embodiment 1: a kind of internal and external adjustment temperature reactor, comprises reactor body 1, reactor jacket 2, agitator 3 and reactor support 4, and described reactor body 1 is arranged on the reactor support 4; The reaction The upper end of the reactor body 1 is provided with at least one reactor body feed port 11; the lower end of the reactor body 1 is provided with a reactor outlet port 12; the reactor jacket 2 is arranged on the outside of the reactor body 1; An external heat exchange cavity 21 is formed between the reactor jacket 2 and the reactor body 1; the lower end of the reactor jacket 2 is provided with a water inlet of the reactor jacket 2; the upper end of the reactor jacket 2 The reactor jacket 2 water outlet is provided; the agitator 3 is arranged on the center line of the reactor body 1; the agitator 3 includes a servo motor 31, a stirring shaft 32 and a stirring paddle 33; the servo motor 31 is set On the top of the reactor body 1; the stirri...

Embodiment 2

[0021] Embodiment 2: a kind of internal and external adjustment temperature reactor, comprises reactor body 1, reactor jacket 2, agitator 3 and reactor support 4, and described reactor body 1 is arranged on the reactor support 4; The reaction The upper end of the reactor body 1 is provided with at least one reactor body feed port 11; the lower end of the reactor body 1 is provided with a reactor outlet port 12; the reactor jacket 2 is arranged on the outside of the reactor body 1; An external heat exchange cavity 21 is formed between the reactor jacket 2 and the reactor body 1; the lower end of the reactor jacket 2 is provided with a water inlet of the reactor jacket 2; the upper end of the reactor jacket 2 The reactor jacket 2 water outlet is provided; the agitator 3 is arranged on the center line of the reactor body 1; the agitator 3 includes a servo motor 31, a stirring shaft 32 and a stirring paddle 33; the servo motor 31 is set On the top of the reactor body 1; the stirri...

Embodiment 3

[0022] Embodiment 3: a kind of internal and external adjustment temperature reactor, comprises reactor body 1, reactor jacket 2, agitator 3 and reactor support 4, and described reactor body 1 is arranged on the reactor support 4; The reaction The upper end of the reactor body 1 is provided with at least one reactor body feed port 11; the lower end of the reactor body 1 is provided with a reactor outlet port 12; the reactor jacket 2 is arranged on the outside of the reactor body 1; An external heat exchange cavity 21 is formed between the reactor jacket 2 and the reactor body 1; the lower end of the reactor jacket 2 is provided with a water inlet of the reactor jacket 2; the upper end of the reactor jacket 2 The reactor jacket 2 water outlet is provided; the agitator 3 is arranged on the center line of the reactor body 1; the agitator 3 includes a servo motor 31, a stirring shaft 32 and a stirring paddle 33; the servo motor 31 is set On the top of the reactor body 1; the stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com